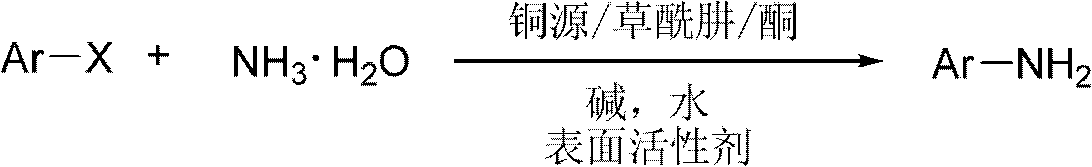

Method for preparing aromatic primary amine by taking ammonia water as ammonia source in water phase system

An aromatic primary amine, ammonia water technology, applied in the field of chemistry, can solve the problems of limited functional group tolerance, unsatisfactory benzene conversion rate, long reaction time, etc. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

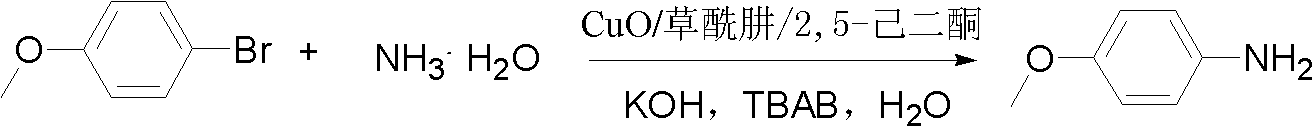

[0024] Example 1: Synthesis of p-methoxyaniline

[0025]

[0026] 4mg (0.025mmol) CuO, 24mg (0.2mmol) oxalazide, 57mg (0.5mmol) 2,5-hexanedione, 187mg (1.0mmol) p-methoxybromobenzene, 840mg (6.0mmol) ammonia water, 112mg (2.0mmol) KOH, 81mg (0.25mmol) TBAB, and 1ml water were added to a 10ml reaction tube, and stirred at room temperature for 72h. After the reaction stopped, it was extracted with ethyl acetate, washed with water and saturated brine respectively, dried over anhydrous sodium sulfate, filtered, and the solvent was distilled off under reduced pressure, and the obtained reaction mixture was separated and purified by silica gel column chromatography [eluent : Petroleum ether / ethyl acetate (20:1)], 107 mg of p-methoxyaniline was obtained, and the yield was 87%.

[0027] ESI-MS: m / z=124[M+H] + ; 1 H NMR (300MHz, CDCl 3 ): δ6.72 (d, J=8.8Hz, 2H), 6.62 (d, J=8.8Hz, 2H), 3.72 (s, 3H), 3.24 (br s, 2H).

Embodiment 2

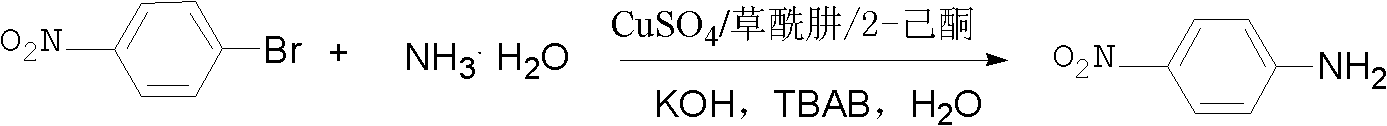

[0028] Embodiment 2: the synthesis of p-nitroaniline

[0029]

[0030] 63mg (0.25mmol) CuSO 4 ·5H 2 O, 59mg (0.5mmol) oxalazide, 200mg (2.0mmol) 2-hexanone, 202mg (1.0mmol) p-nitrobromobenzene, 560mg (4.0mmol) ammonia water, 168mg (3.0mmol) KOH, 32.2mg (0.1 mmol) TBAB, 1ml H 2 O was added to a 10ml reaction tube, heated in an ordinary oil bath at 90°C and stirred for 30min. After the reaction stopped, it was extracted with ethyl acetate, washed with water and saturated brine respectively, dried over anhydrous sodium sulfate, filtered, and the solvent was distilled off under reduced pressure, and the obtained reaction mixture was separated and purified by silica gel column chromatography [eluent : Petroleum ether / ethyl acetate (10:1)] to obtain 112 mg of p-nitroaniline, with a yield of 81%.

[0031] ESI-MS: m / z=139[M+H] + ; 1 H NMR (300 MHz, DMSO): δ 7.90 (d, J=9.2 Hz, 2H), 6.67 (s, 2H), 6.56 (d, J=9.2 Hz, 2H).

Embodiment 3

[0032] Embodiment 3: the synthesis of p-chloroaniline

[0033]

[0034] 19mg (0.1mmol) CuI, 59mg (0.5mmol) oxalazide, 57mg (0.5mmol) 2,5-hexanedione, 192mg (1.0mmol) p-chlorobromobenzene, 1.6g (10.0mmol) ammonia water, 56mg ( 1.0mmol) KOH, PEG400 (0.2ml), 2.0ml H 2 O was added to a 10ml reaction tube, heated in an ordinary oil bath at 120°C and stirred for 5 minutes. After the reaction stopped, it was extracted with ethyl acetate, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and the solvent was distilled off under reduced pressure. The resulting reaction mixture was separated and purified by silica gel column chromatography [eluent: petroleum Ether / ethyl acetate (20:1)] to obtain 104 mg of p-chloroaniline with a yield of 82%.

[0035] ESI-MS: m / z=128[M+H] + ; 1 H NMR (300MHz, CDCl 3 ): δ7.09 (d, J=8.8Hz, 2H), 6.60 (d, J=8.8Hz, 2H), 3.68 (br s, 2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com