Residual oil hydrogenation process method and reactor

A technology of residue hydrogenation and process method, applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc., can solve the problems of phase separation and coking, unsuitable control of reaction temperature and shell temperature, etc. , to prevent the aggregation and phase separation process, reduce the probability of mutual collision, and avoid coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

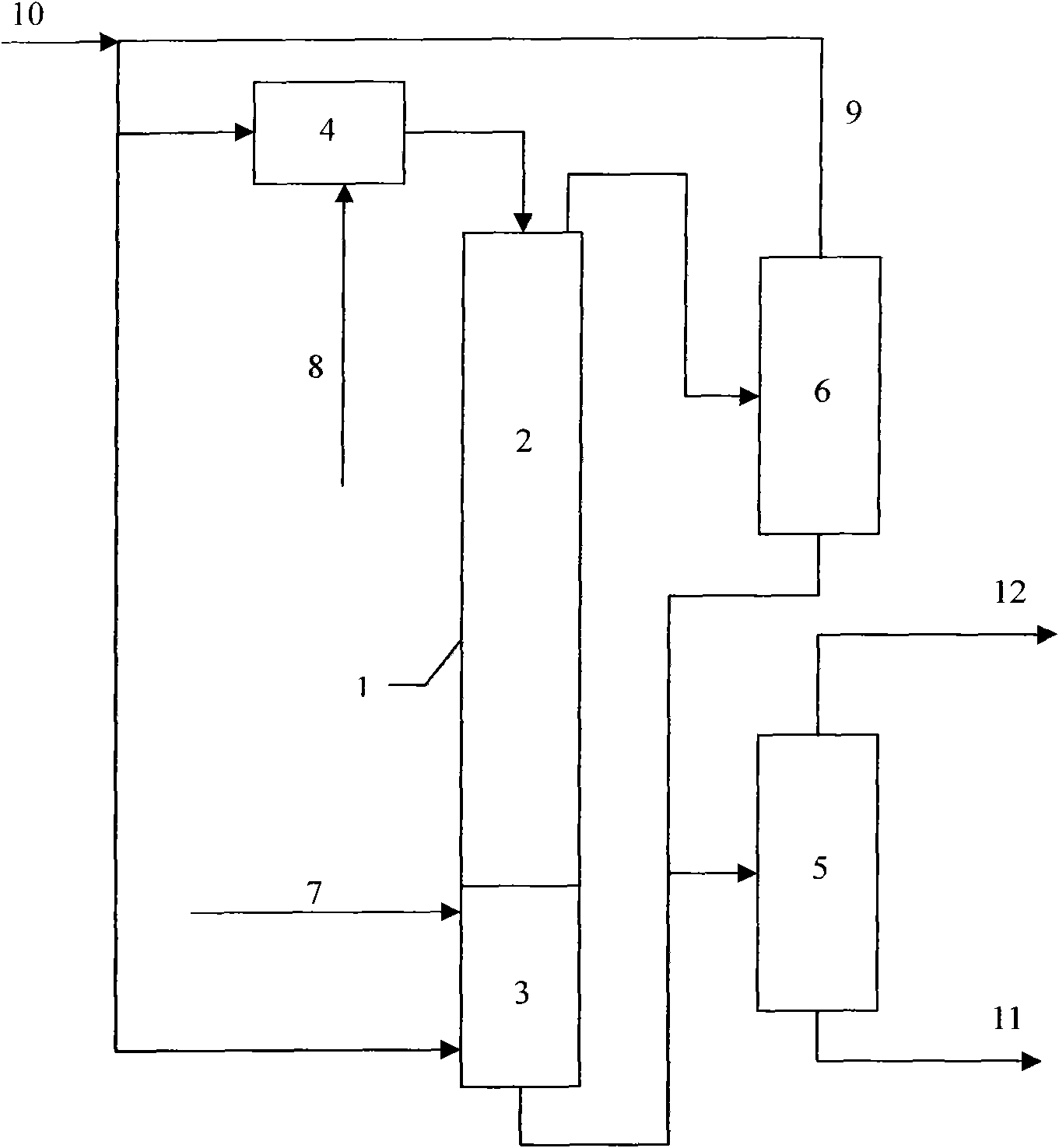

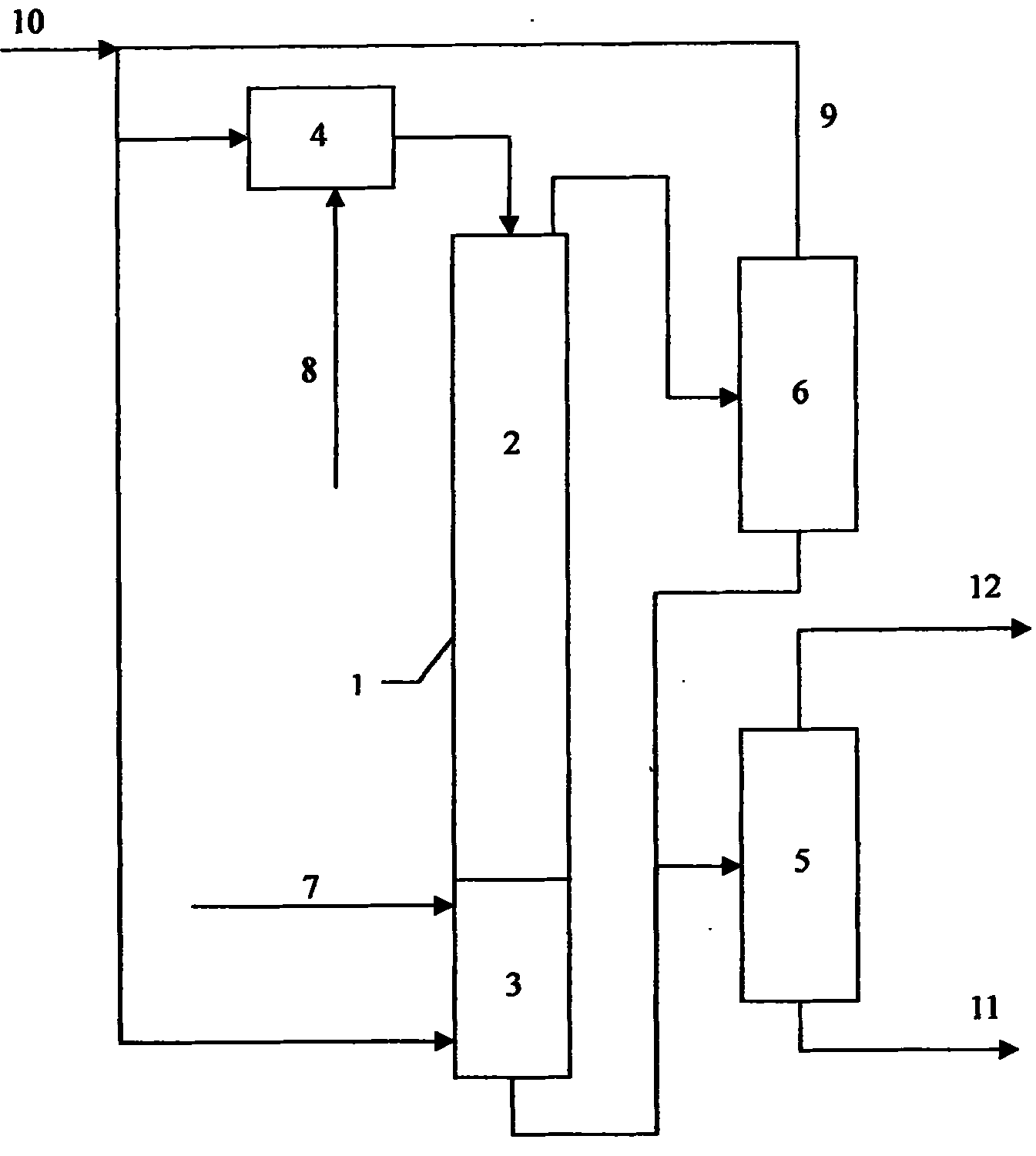

[0032] This example is an implementation of residual oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

[0033] The raw material oil 8, fresh hydrogen gas 10, and circulating hydrogen gas 9 added to the suspended bed homogeneous catalyst enter the hydrogen dissolving mixer for enhanced contact, so that the hydrogen gas is fully dissolved in the raw material oil. The hydrogen oil mixture enters the atomization reaction zone 2 in the reactor 1 for hydrogenation and cracking reactions. The reacted liquid stream drops into the liquid phase stable zone 3, and the stable oil rich in aromatics in the liquid phase stable zone is in countercurrent contact with hydrogen to form a stable dispersion system with the reacted liquid stream. The effluent stream from the reactor enters the high-pressure separator and the low-pressure separator respectively, the separated hydrogen is recycled, and the separated liquid enters the fractionation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com