Long-acting environmental-protection general-purpose water-base metal working fluid

A metal working fluid, general-purpose technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of not meeting the requirements of modern production and environmental protection, and achieve the reduction of surface roughness value, reduction of cutting and grinding force, prolongation of The effect of tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] A long-acting environment-friendly general-purpose water-agent metal working fluid, its components and the weight ratio are: nonionic surfactant H: 20-25, triethanolamine oleate: 25-30, synthetic extreme pressure agent: 10 -15. Coagulant: 3-5 and defoamer: 2-3.

[0021] The nonionic surfactant H is a product obtained by further neutralizing the copolymer obtained by the copolymerization reaction of rosin and maleic anhydride with polyamine, and the product is a reddish-brown viscous liquid.

[0022] The triethanolamine oleate is a triethanolamine oleate product prepared by esterification of oleic acid and trihexanolamine.

[0023] The synthetic extreme pressure agent is a product prepared by adjusting components and weight ratios as lubricant additive: 10-15, rust inhibitor: 5-10 and foam inhibitor: 2-5.

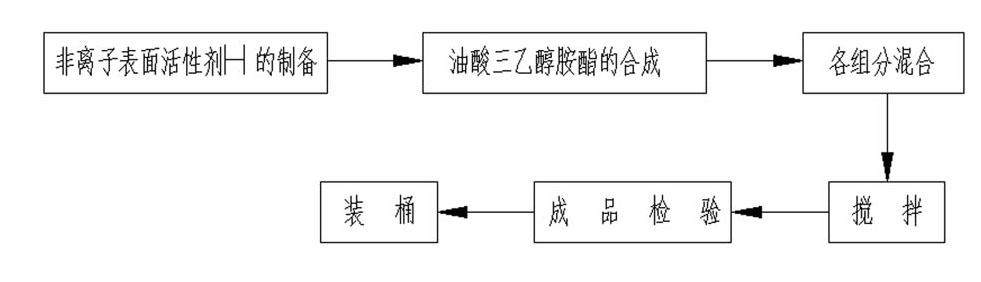

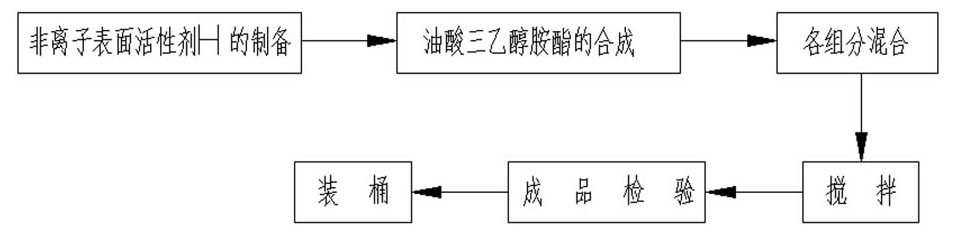

[0024] see figure 1 , the method for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com