Method for producing lactic acid by fermentation of acorn powder

A kind of technology of acorn powder and lactic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem that acorn powder has not been widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

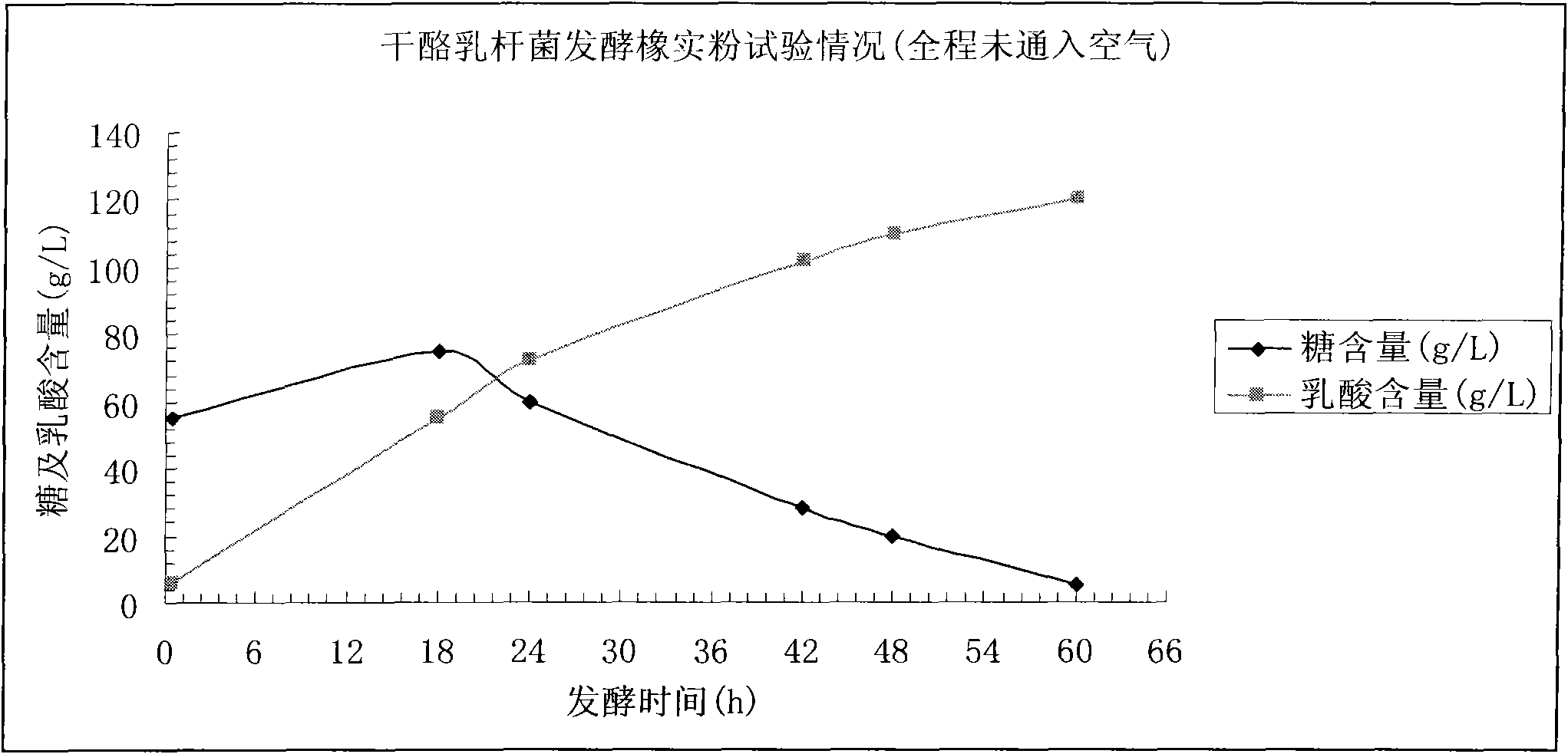

[0029] Lactobacillus casei fermentation test (no air was introduced during the fermentation process)

[0030] Add 2kg of acorn powder (acorn powder mesh number 100, tannin content 0.5wt%) to 7L of tap water, add 1kg of light calcium carbonate, 2.0mL of high-temperature amylase (40000U / mL), liquefy at 92°C for 1 hour, and cool to 50°C , add 7.0mL starch glucoamylase (30000U / mL), keep warm for 3h, measure the glucose concentration as 55g / L.

[0031] Lactobacillus casei (Lactobacillus casei) was cultured to the logarithmic phase in the MRS medium, and 1.2 L of the seed culture solution was added to the fermenter. 42°C, 100rpm, pH value 5.0, fermented for 48h, the lactic acid concentration reached the maximum value of 120g / L.

Embodiment 2

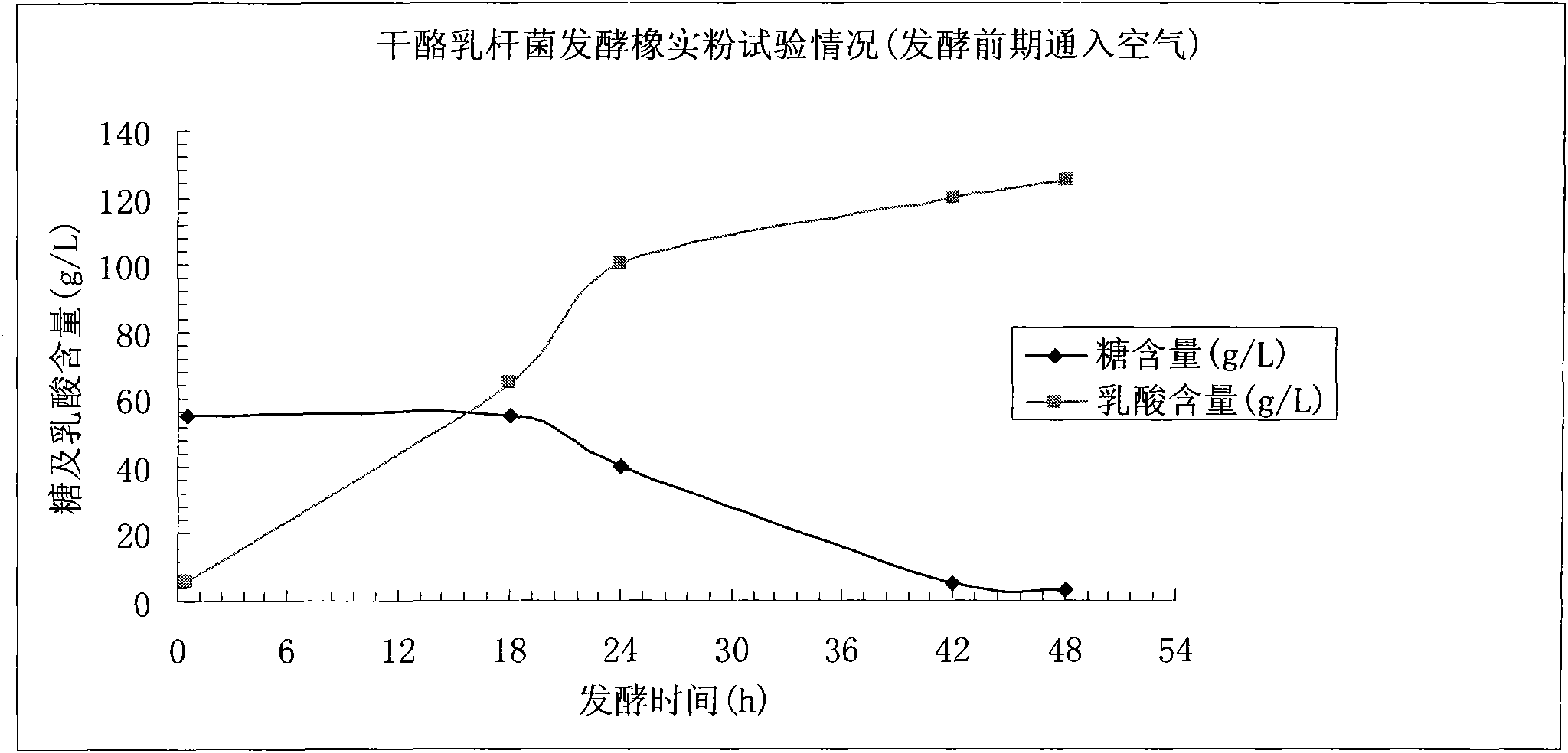

[0033] Lactobacillus casei fermentation test (air in the early stage of fermentation)

[0034] Add 2kg acorn powder (acorn powder mesh number 100, tannin content 0.5wt%) to 7L tap water, add 1kg light calcium carbonate, 0.36kg soybean meal powder, 2.0mL high-temperature amylase (40000U / mL), liquefy at 92°C for 1h , lower the temperature to 50°C, add 7.0mL starch glucoamylase (30000U / mL), keep warm for 3h, and measure the glucose concentration to be 55g / L.

[0035] Lactobacillus casei (Lactobacillus casei) was cultured to the logarithmic phase through the MRS medium, and added to the fermenter. After inoculation, air is introduced, and the volumetric space velocity is 15h -1 , maintain 6h. 42°C, 100rpm, pH value 5.0, co-fermentation for 48h, the lactic acid concentration reached the maximum value of 125g / L.

Embodiment 3

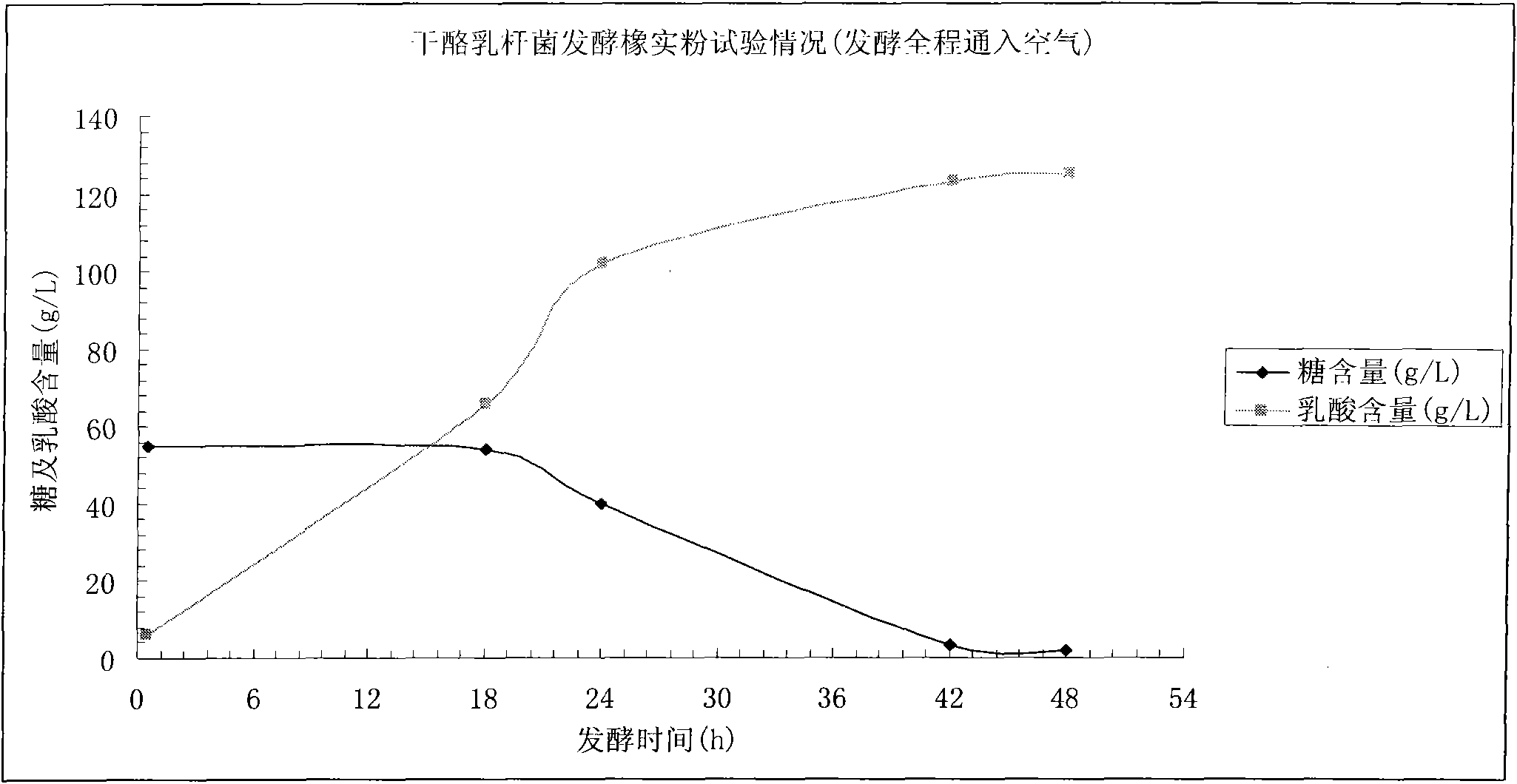

[0037] Lactobacillus casei fermentation test (breathing air throughout the fermentation process)

[0038] Add 2kg of acorn powder (acorn powder mesh number 100, tannin content 0.5wt%) to 7L of tap water, add 1kg of light calcium carbonate, 2.0mL of high-temperature amylase (40000U / mL), liquefy at 92°C for 1 hour, and cool to 50°C , add 7.0mL starch glucoamylase (30000U / mL), keep warm for 3h, measure the glucose concentration as 55g / L.

[0039] Lactobacillus casei (Lactobacillus casei) was cultured to the logarithmic phase in the MRS medium, and 1.2 L of the seed culture solution was added to the fermenter. After inoculation, air is introduced, and the volumetric space velocity is 15h -1 , 42°C, 100rpm, pH value 5.0, fermented for 48h, the lactic acid concentration reached the maximum value of 125g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com