Electric contact material made of silver-tungsten carbide graphite and preparation method thereof

A technology of tungsten carbide graphite and contact materials, which is applied to contacts, electrical components, electrical switches, etc., can solve the problem of meeting the requirements of high reliability and electromagnetic compatibility, oxidation resistance, and welding resistance of the fourth-generation low-voltage electrical appliances. Poor resistance to arc burnout, limited application fields of contact materials, etc., to achieve the effects of high reliability, high electrical life, and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

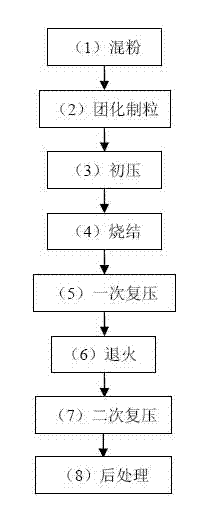

[0022] Example 1 , refer to figure 1 , taking the preparation of AgWC9.6ZrC2.4C3 with a specification of 7.5×7.5×2.5mm as an example.

[0023] (1) Ag powder was mixed with tungsten carbide-zirconium carbide solid solution and graphite at a ratio of 85:12:3, mixed with 0.3% Ni and 0.7% B for 6 hours, and the ball-to-material ratio was 1:1, and dried in vacuum. Agglomerate granulation at 700°C in a hydrogen atmosphere for 4 hours to obtain a mixed powder with good fluidity, wherein the ratio of tungsten carbide to zirconium carbide in the tungsten carbide-zirconium carbide solid solution is 8:2;

[0024] (2) Press the granulated mixed powder into a 7.5×7.5×3.5mm compact, with an initial pressure of 150MPa;

[0025] (3) Sinter the compact in a hydrogen atmosphere at 880°C for 4 hours;

[0026] (4) Repress the sintered body with a pressure of 250MPa, and the thickness of the green body is 2.8mm;

[0027] (5) Anneal the green body after re-pressing at 500°C for 2 hours in a hy...

Embodiment 2

[0031] Example 2 , taking the preparation of AgWC9.8ZrC4.2C2 with a specification of 6×6×2mm as an example.

[0032] (1) Mix Ag powder with tungsten carbide-zirconium carbide solid solution and graphite at a ratio of 84:14:2, wet mix with 0.4% Cr for 4 hours, the ball-to-material ratio is 3:1, dry in vacuum, and dry in a hydrogen atmosphere 750°C, 3 hours for agglomeration and granulation to obtain a mixed powder with good fluidity, wherein the ratio of tungsten carbide to zirconium carbide in the tungsten carbide-zirconium carbide solid solution is 7:3;

[0033] (2) Press the granulated mixed powder into a 6×6×2.8mm compact, and the initial pressure is 180MPa.

[0034] (3) The compact is sintered in a hydrogen atmosphere at 900°C for 3 hours;

[0035] (4) Repress the sintered body with a pressure of 280MPa, and the thickness of the green body is 2.2mm;

[0036] (5) Anneal the green body after re-pressing at 600°C for 4 hours in a hydrogen atmosphere;

[0037] (6) Repress...

Embodiment 3

[0040] Example 3 , taking the preparation of AgWC10.8ZrC1.2C3 with a specification of 11×9×2mm as an example.

[0041] (1) Ag powder was mixed with tungsten carbide-zirconium carbide solid solution and graphite at a ratio of 85:12:3, mixed with 0.3% Ni and 0.7% B for 6 hours, and the ball-to-material ratio was 1:1, and dried in vacuum. Agglomerate granulation at 700°C in a hydrogen atmosphere for 4 hours to obtain a mixed powder with good fluidity, wherein the ratio of tungsten carbide to zirconium carbide in the tungsten carbide-zirconium carbide solid solution is 9:1;

[0042] (2) Press the granulated mixed powder into a 11×9×2.8mm compact, with an initial pressure of 150MPa;

[0043] (3) The compact is sintered in a hydrogen atmosphere at 880°C for 4 hours;

[0044] (4) Repress the sintered body with a pressure of 250MPa, and the thickness of the green body is 2.2mm;

[0045] (5) Anneal the repressed green body at 500°C for 2 hours in a hydrogen atmosphere;

[0046] (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com