Novel macromolecule liposome and preparation method thereof

A polymer and liposome technology, applied in the field of medicine, can solve the problems of limited application and large cell toxicity, and achieve the effect of low cytotoxicity, good stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

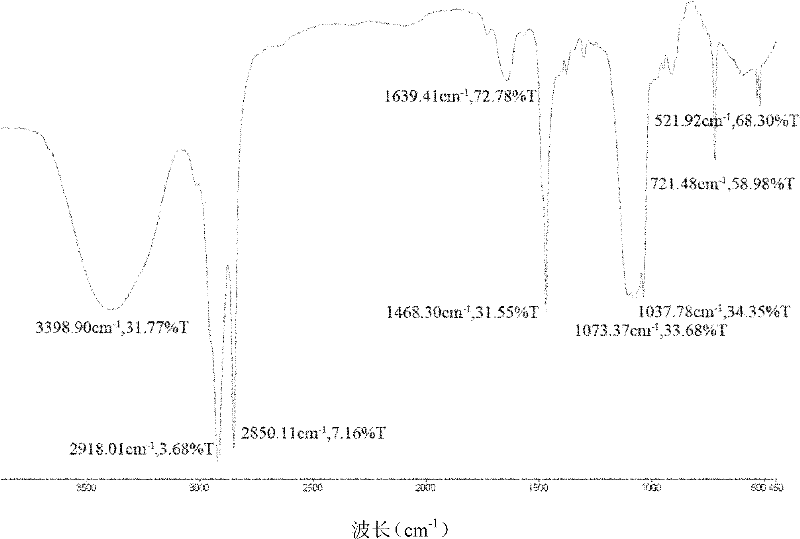

[0033] Synthesis of γ-polyglutamic acid stearyl quaternary ammonium salt. Take 2g of γ-polyglutamic acid and 50g of dimethylglycidyl octadecyl ammonium chloride into a four-necked flask, add 150mL of isopropanol to the flask, stir magnetically, heat to 50°C, condense and reflux Reaction for 3 days. After the reaction, the product was evaporated using a rotary evaporator to distill the isopropanol out, and then the product was placed in a dialysis bag of 8000-14000 for 7 days, the lower layer of gel was removed, filtered and lyophilized to obtain γ-polyglutamic acid Octadecyl quaternary ammonium salt. Such as figure 1 Infrared analysis test results show that 3,398.90 peaks have broad bands, which are the result of -OH hydrogen bonding; 1,639.41 peaks prove that the sample contains -NH-CO-, derived from γ-polyglutamic acid; 1073.37 peaks It proves that the tested sample contains -CO- and is ester; and the peak at 721.48 proves that the sample contains (CH 2 ) n (n≥4), derived...

Embodiment 2

[0035] Synthesis of γ-polyglutamic acid stearyl quaternary ammonium salt. Take 4g of γ-polyglutamic acid and 150g of dimethylglycidyl octadecylammonium chloride into a four-necked flask, add 200mL of isopropanol to the flask, stir magnetically, heat to 60°C, condense and reflux Reaction for 5 days. After the reaction, the product was evaporated using a rotary evaporator to distill the isopropanol out, and then the product was placed in a dialysis bag of 8000-14000 for dialysis for 3 days, the lower layer of gel was removed, filtered and lyophilized to obtain γ-polyglutamic acid Octadecyl quaternary ammonium salt.

Embodiment 3

[0037] Synthesis of γ-polyglutamic acid stearyl quaternary ammonium salt. Take 4g of γ-polyglutamic acid and 200g of dimethylglycidyl octadecylammonium chloride into a four-necked flask, add 250mL of isopropanol to the flask, stir magnetically, heat to 70°C, condense and reflux Reaction for 1 day. After the reaction is over, use a rotary evaporator to distill the isopropanol out, then put the product into a dialysis bag of 8000-14000 for 10 days, remove the lower layer of gel, filter and freeze-dry to obtain γ-polyglutamic acid Octadecyl quaternary ammonium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com