Surface functional titanium material and preparation method thereof

A technology of surface functionalization and titanium material, which is applied in the field of biomedical materials to achieve the effect of reducing thrombosis, good application prospect and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

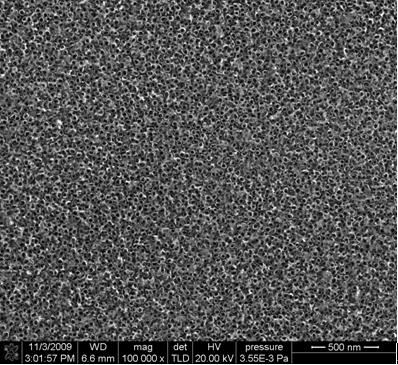

[0033] Embodiment 1, surface functionalized titanium material (TiO 2 Preparation of nanotubes with a diameter of 30nm)

[0034] Include the following steps:

[0035] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 10 minutes in sequence, and drying at 37°C for later use;

[0036] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 10V, soak the oxidized titanium material in deionized water for 2 hours, wash it with deionized water for 5 times, and dry it with nitrogen gas to obtain a tube with a surface. TiO with a diameter of 30nm 2 Titanium material of nanotube array (FE-SEM pictu...

Embodiment 2

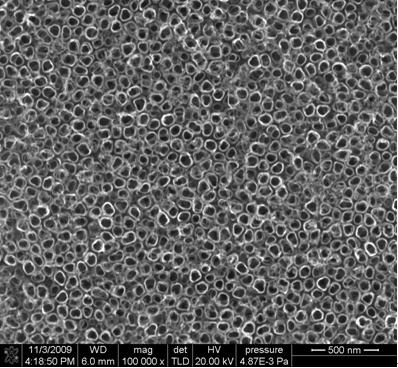

[0041] Embodiment 2, surface functionalized titanium material (TiO 2 Preparation of nanotubes with a diameter of 60nm)

[0042] Include the following steps:

[0043] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 10 minutes in sequence, and drying at 37°C for later use;

[0044] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 20V, soak the oxidized titanium material in deionized water for 2 hours, wash it with deionized water for 5 times, and dry it with nitrogen gas to obtain a tube with a surface. TiO with a diameter of 60nm 2 Titanium material of nanotube array (FE-SEM pictu...

Embodiment 3

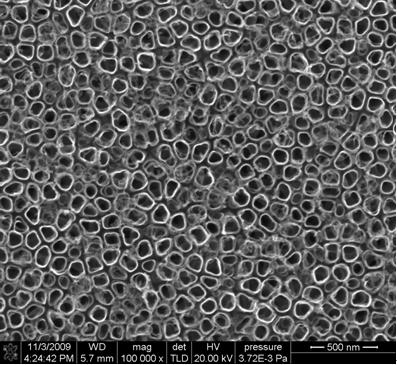

[0049] Embodiment 3, surface functionalized titanium material (TiO 2 Preparation of nanotubes with a diameter of 100nm)

[0050] Include the following steps:

[0051] a. Ultrasonic cleaning the titanium material with acetone, absolute ethanol, and deionized water for 10 minutes in sequence, and drying at 37°C for later use;

[0052] b, dissolving ammonium fluoride with a volume fraction of 50% ethanol solution to make a solution with a concentration of 0.27mol / L, as the electrolyte; then the titanium material pretreated in step a is used as the anode, and the platinum electrode is used as the cathode. In the above-mentioned ammonium fluoride electrolyte, electrolyze for 3 hours under the action of a direct current of 25V, soak the oxidized titanium material in deionized water for 2 hours, wash it with deionized water for 5 times, and dry it with nitrogen gas to obtain a tube with a surface. TiO with a diameter of 100nm 2 Titanium material of nanotube array (FE-SEM pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com