Solvent recovery method and device for organic solvent-containing dye and coating waste

A solvent recovery device and technology for organic solvents, applied in separation methods, chemical instruments and methods, distillation separation, etc., can solve the problems of slow heating speed, time-consuming loading and unloading processes, low heat conduction efficiency, etc., and achieve heating and cooling. The effect of high speed, high temperature control accuracy and high solvent recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions and effects of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

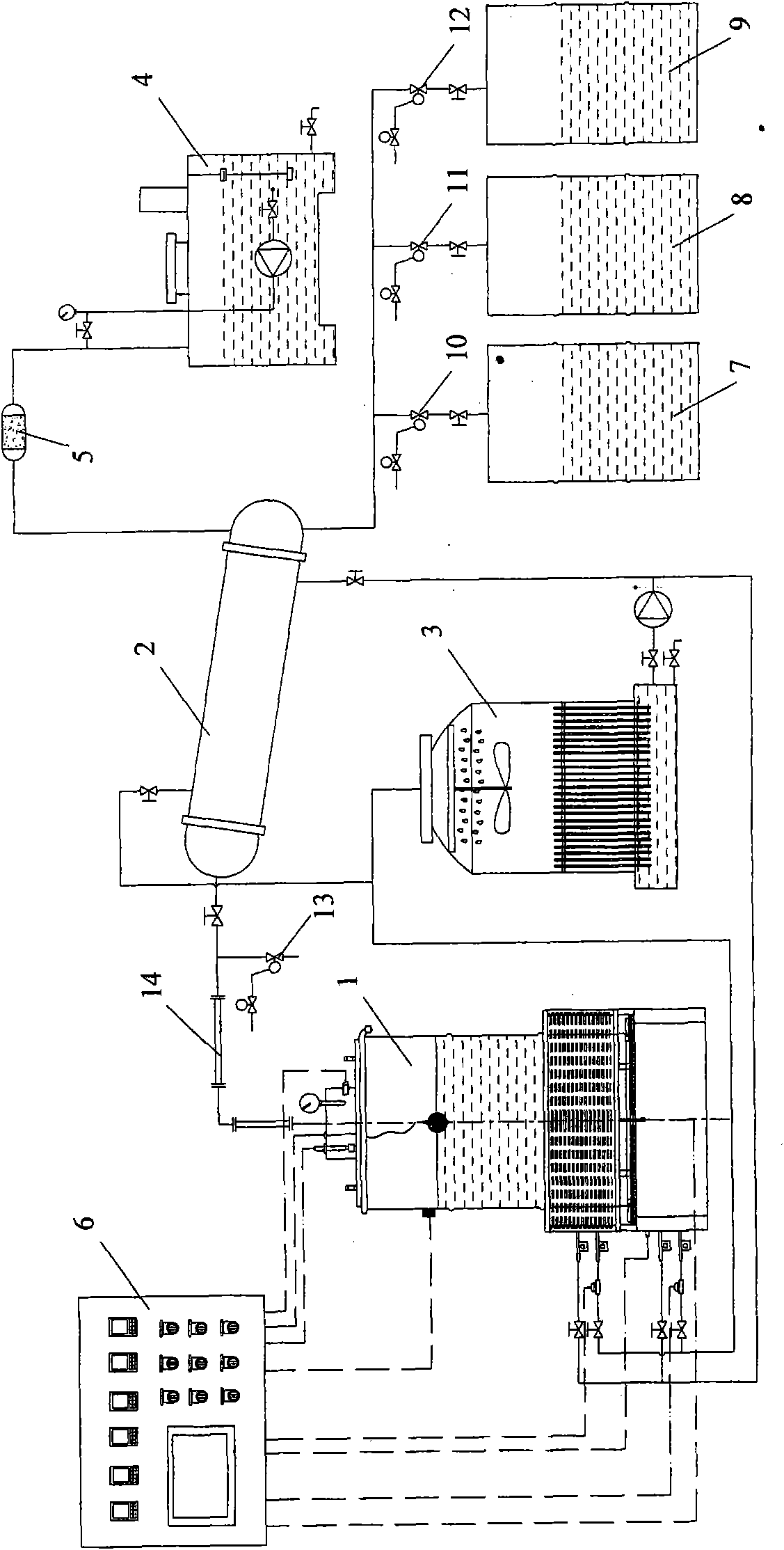

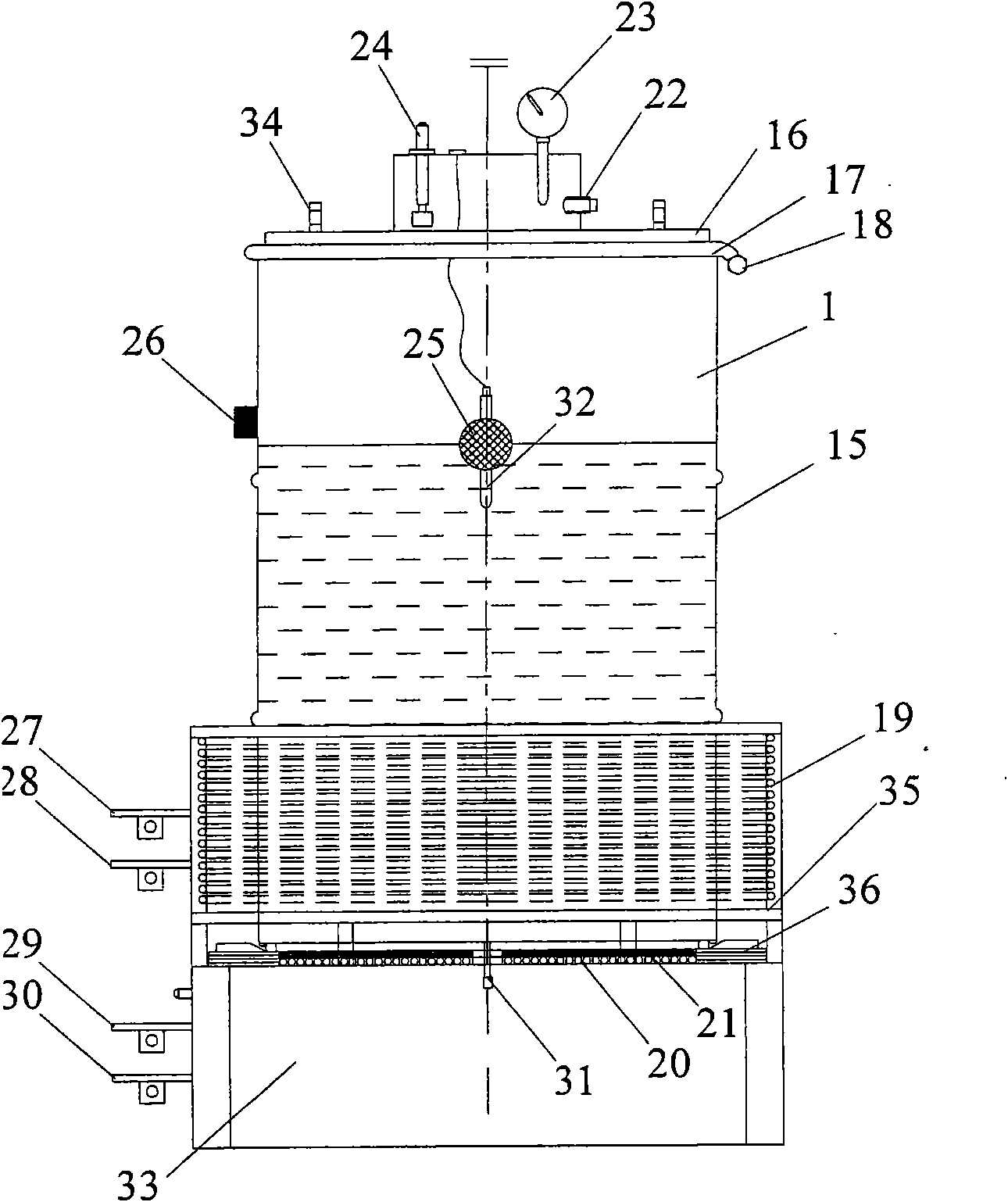

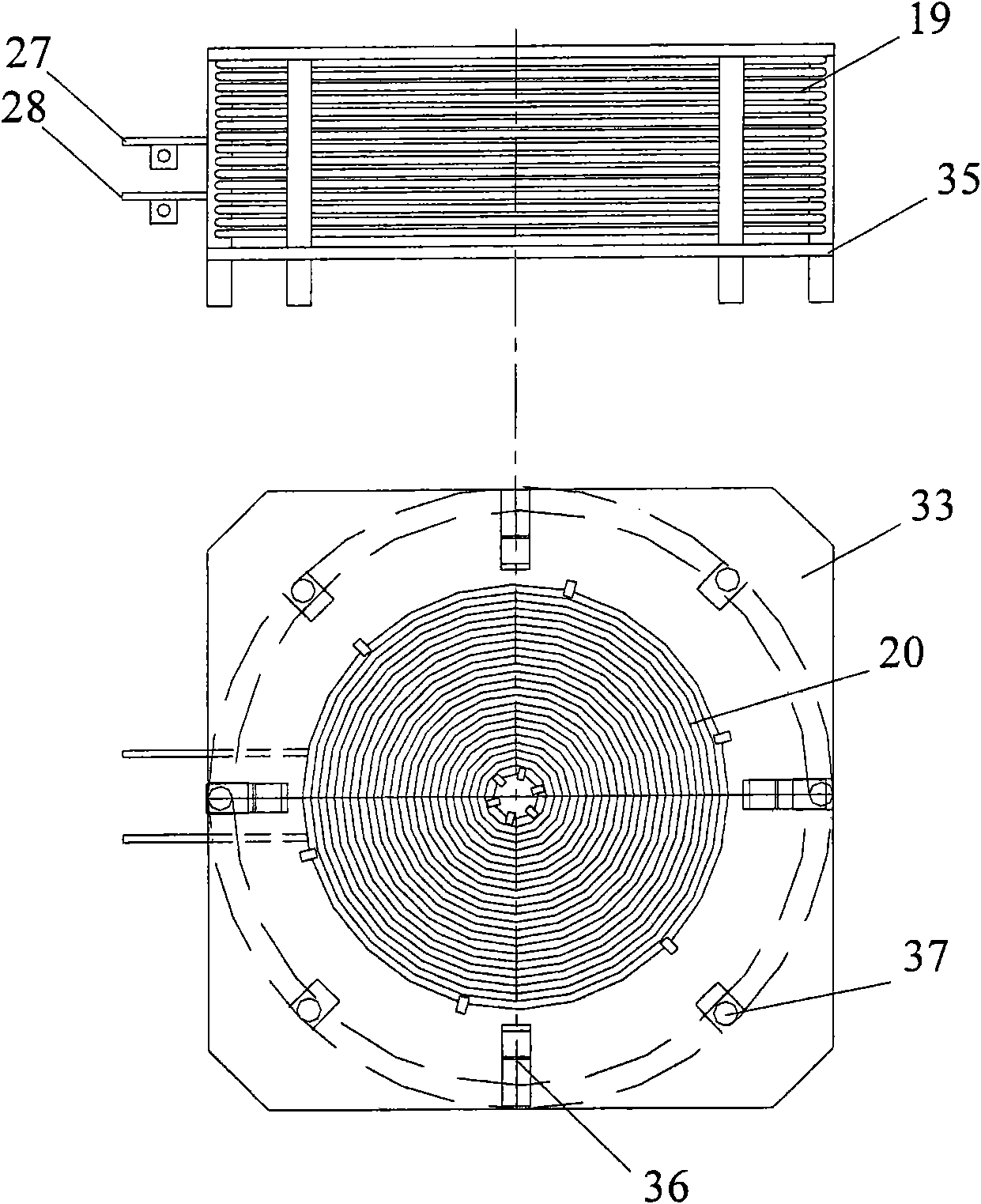

[0057] figure 1 It is a schematic diagram of a solvent recovery device for dye paint waste containing organic solvents of the present invention. Such as figure 1 As shown, the solvent recovery device of the present invention is mainly composed of a solvent recovery heating device 1, a condenser 2, a circulating water cooling tower 3, a water flow exhaust fan 4, an electric control cabinet 6, and regenerated solvent storage tanks 7, 8, and 9. The solvent recovery heating device 1 and the condenser 2 are connected through a solvent vapor delivery pipe 14, and a liquid discharge and pressure relief valve 13 is arranged on the solvent vapor delivery pipe 14, and the rear end of the condenser 2 is connected to the regeneration solvent storage tank 7, 8 , 9 and the water flow type exhaust fan 4 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com