A titanium-based composite anode for manganese electrolysis, preparation method and application thereof

A composite anode and electrolytic manganese technology, applied in the field of electrochemistry, can solve the problems of complex preparation of nano-titanium dioxide layers and difficult industrial application, and achieve the effects of no cleaning process, long service life, and tight adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

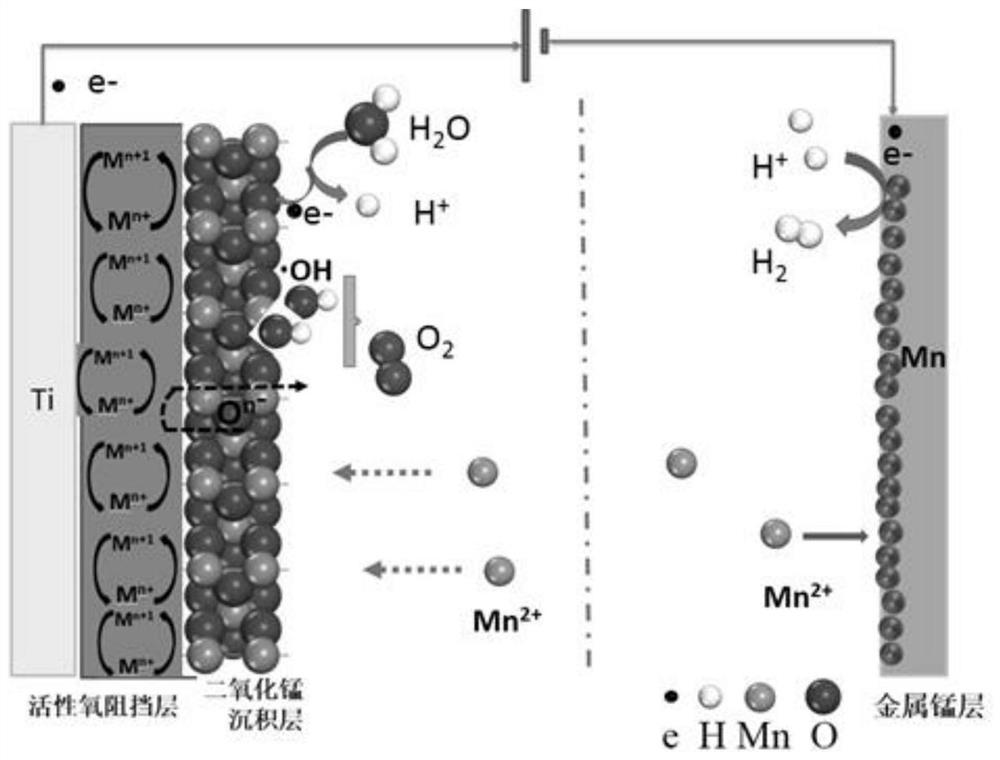

[0043] Such as figure 1 As shown, the titanium-based composite anode in this embodiment includes a titanium substrate, an active oxygen barrier layer and a manganese dioxide deposition layer. Among them, the titanium substrate is pure titanium sheet, and the active oxygen barrier layer is Ca 2 mn 2 o 5 layer, and the manganese dioxide deposition layer is in-situ electrodeposited on the surface of the active oxygen barrier layer.

[0044] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0045](1) Titanium sheet pretreatment: Polish the titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and then polish the titanium sheet to a smooth surface. Piece into HF:HNO 3 = Activate in a mixed acid solution of 1:2 for 30s, wash and dry;

[0046] (2) Preparation of active oxygen barrier layer: Calcium acetate and ma...

Embodiment 2

[0059] The structure of the titanium-based composite anode in this example is the same as in Example 1, but the active oxygen barrier layer is CoMn 2 o 4 layer.

[0060] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0061] (1) Titanium sheet pretreatment: Polish the titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and then polish the titanium sheet to a smooth surface. Piece into HF:HNO 3 =1:2 mixed acid solution for activation for 60s, cleaning and drying;

[0062] (2) Preparation of active oxygen barrier layer: Dissolve manganese acetate and cobalt acetate in a mixture of ethylene glycol and citric acid solution at an atomic ratio of 2:1, and then coat the resulting solution on the surface of the above-mentioned electrode. Place it under the muffle furnace and roast for 15 minutes, this process is...

Embodiment 3

[0074] The structure of the titanium-based composite anode in this example is the same as in Example 1, but the active oxygen barrier layer is NiCo 2 o 4 layer.

[0075] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0076] (1) Titanium sheet pretreatment: Polish the titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 20 minutes, and then polish the titanium sheet to a smooth surface. Piece into HF:HNO 3 = Activate in a mixed acid solution of 1:2 for 30s, wash and dry;

[0077] (2) Preparation of active oxygen barrier layer: Dissolve nickel acetate and cobalt acetate in a mixture of ethylene glycol and citric acid solution at an atomic ratio of 1:2, and then coat the resulting solution on the surface of the above electrode, and heat it at 500°C Place it under the muffle furnace and roast for 15 minutes, this proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com