Surface-hydrophilic molecularly imprinted polymer microsphere and preparation method thereof

A hydrophilic polymer and molecular imprinting technology, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and other chemical processes, can solve the problem of affecting the molecular recognition ability of products, uncontrollable polymerization process, molecular imprinted polymer microsphere surface, etc. Issues such as uneven coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

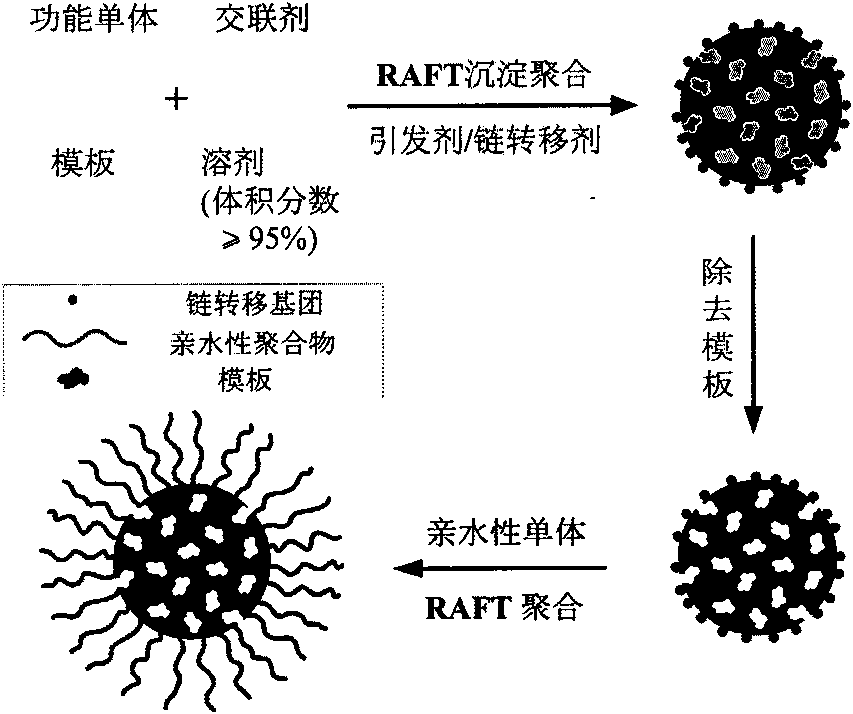

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

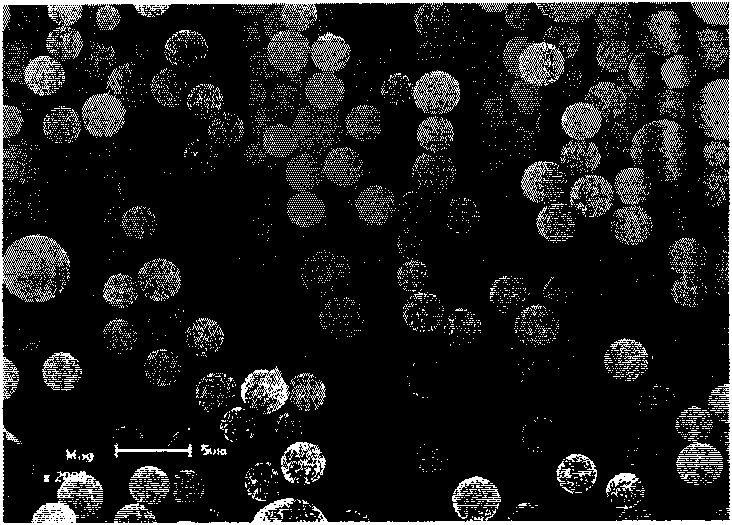

[0029] Add 0.25mmol of 2,4-D into a 250mL round-bottomed flask filled with 60mL of methanol / water (4:1, v / v), stir it with a magnet to dissolve it completely, and then add 1mmol of 4-vinylpyridine. After full contact for half an hour, 5mmol EDMA, 0.44mmol chain transfer agent cumyl dithiobenzoate (CDB), 0.22mmol azobisisobutyronitrile (AIBN) and 20mL methanol / water (4:1 , v / v). After stirring for half an hour, the reaction system was sealed with argon gas for deoxygenation for 30 minutes, placed in a constant temperature oil bath at 60°C, reacted for 24 hours, and the reaction product was obtained by suction filtration.

[0030] The reaction product was subjected to Soxhelt extraction with methanol / acetic acid (9:1, v / v) for 48h, and then Soxhelt extraction with methanol for 12h. After air drying, vacuum drying at 40°C for 48 hours yielded molecularly imprinted polymer microspheres with narrow particle size distribution and RAFT chain transfer groups on the surface.

[0031]...

example 2

[0035] Add 0.25 mmol of 2,4-D into a 250 ml round-bottomed flask filled with 60 ml of methanol / water (4:1, v / v), stir with a magnet to dissolve it completely, and then add 1 mmol of 4-vinylpyridine. After full contact for half an hour, add 5mmol

[0036] EDMA, 0.44 mmol chain transfer agent CDB, 0.22 mmol AIBN and 20 ml of methanol / water (4:1, v / v). After stirring for half an hour, the reaction system was sealed with argon gas for deoxygenation for 30 minutes, placed in a constant temperature oil bath at 60°C, reacted for 24 hours, and the reaction product was obtained by suction filtration.

[0037] The reaction product was subjected to Soxhelt extraction with methanol / acetic acid (9:1, v / v) for 48h, and then Soxhelt extraction with methanol for 12h. After air drying, vacuum drying at 40°C for 48 hours yielded molecularly imprinted polymer microspheres with narrow particle size distribution and RAFT chain transfer groups on the surface.

[0038] In the preparation of non-im...

example 3

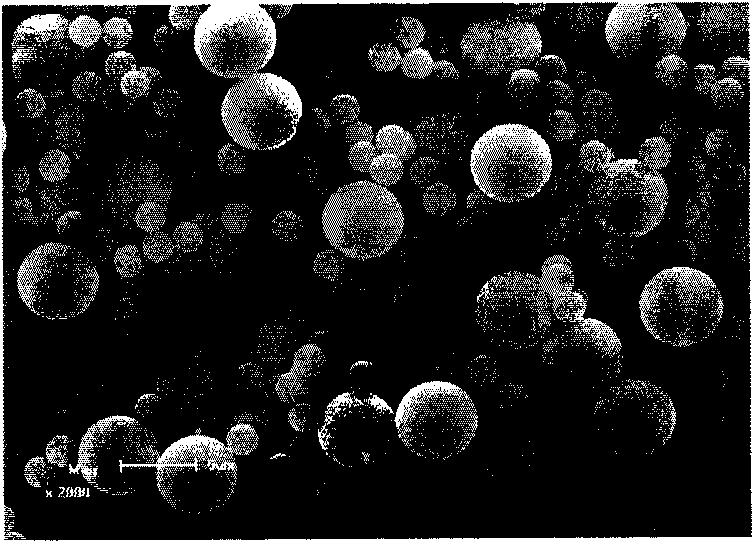

[0042] Add 0.25mmol theophylline and 30mL acetonitrile into a 100mL round bottom flask, stir to dissolve completely, then add 1mmol methacrylic acid, mix thoroughly for half an hour, then add 4mmol EDMA, 0.09mmol chain transfer agent CDB, 0.045mmolAIBN and 10 mL of acetonitrile. After stirring for half an hour, deoxygenate with argon for 30 minutes, seal the reaction system, place it in a constant temperature oil bath at 60°C, react for 24 hours, and filter with suction to obtain the reaction product.

[0043] The obtained polymer microspheres were subjected to Soxhelt extraction with methanol / acetic acid (9:1, v / v) for 48 hours, and then Soxhelt extraction with acetonitrile for 24 hours. Then vacuum-dried at 40°C for 48 hours to obtain molecularly imprinted polymer microspheres with narrow particle size distribution and chain transfer groups on the surface.

[0044] The preparation process of non-imprinted polymer microspheres is the same as above except that no template is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com