Device for online measuring wall thickness of hot-rolled metal pipe by using gamma rays

A metal tube, gamma ray technology, applied in the direction of measuring device, length measuring device, metal rolling, etc., to achieve the effect of expanding the eccentric range, improving the accuracy, and relaxing the conditions of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

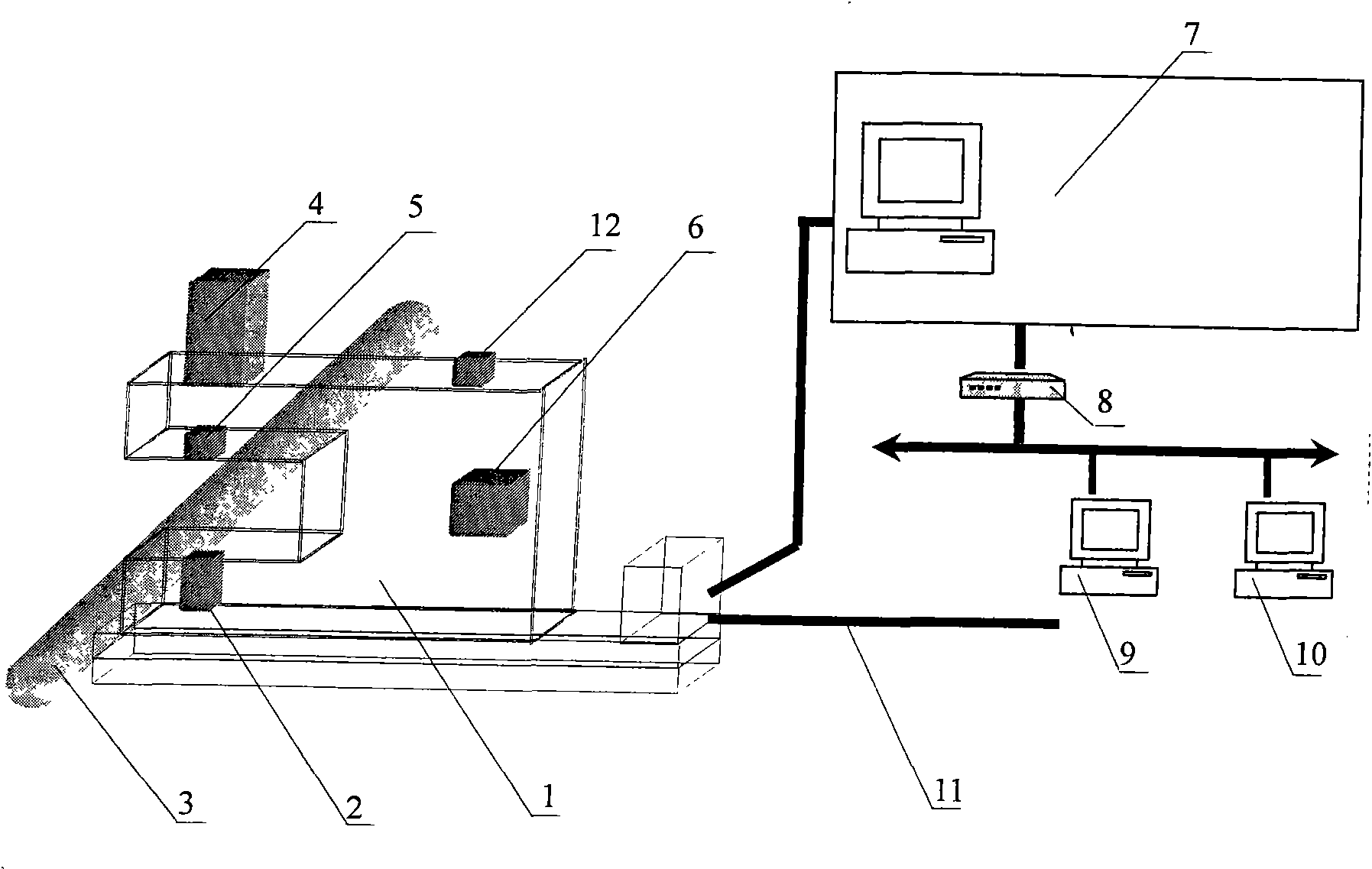

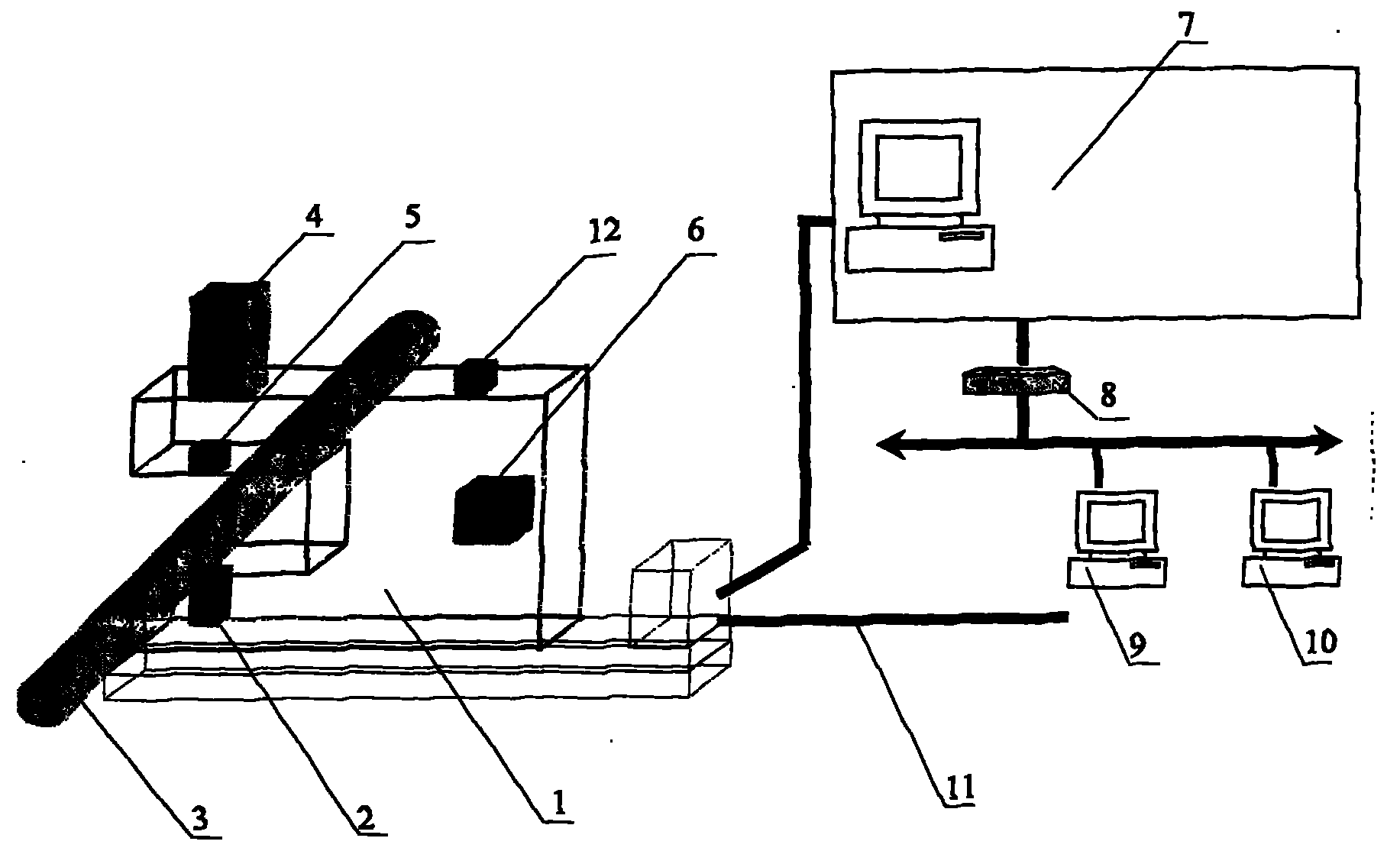

[0026] The present invention uses gamma rays to measure the wall thickness of hot-rolled metal pipes on-line with high precision. The system composition includes:

[0027] Gamma ray thickness gauge: It is composed of a detector, a radiation source and an amplifier circuit, and is used to measure the thickness of the pipe.

[0028] CCD camera: It consists of a set of optical linear array CCD lens (built-in FPGA host) and background light source, used to detect the eccentricity of the pipe.

[0029] Water refrigeration cycle system: used for cooling of on-site measurement equipment (including detectors, radioactive sources and CCD lenses, etc.).

[0030] Gas path processing system: used for purging of on-site measurement equipment and switching radioactive sources. Small PLC system: I / O point control interlock signal and relay output signal.

[0031] Main cabinet of central station: including measurement host system, system power supply and wiring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com