Tetragonal-phase barium titanate nanorod array and preparation method thereof

A technology of nanorod array and phase barium titanate, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of high repeatability and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

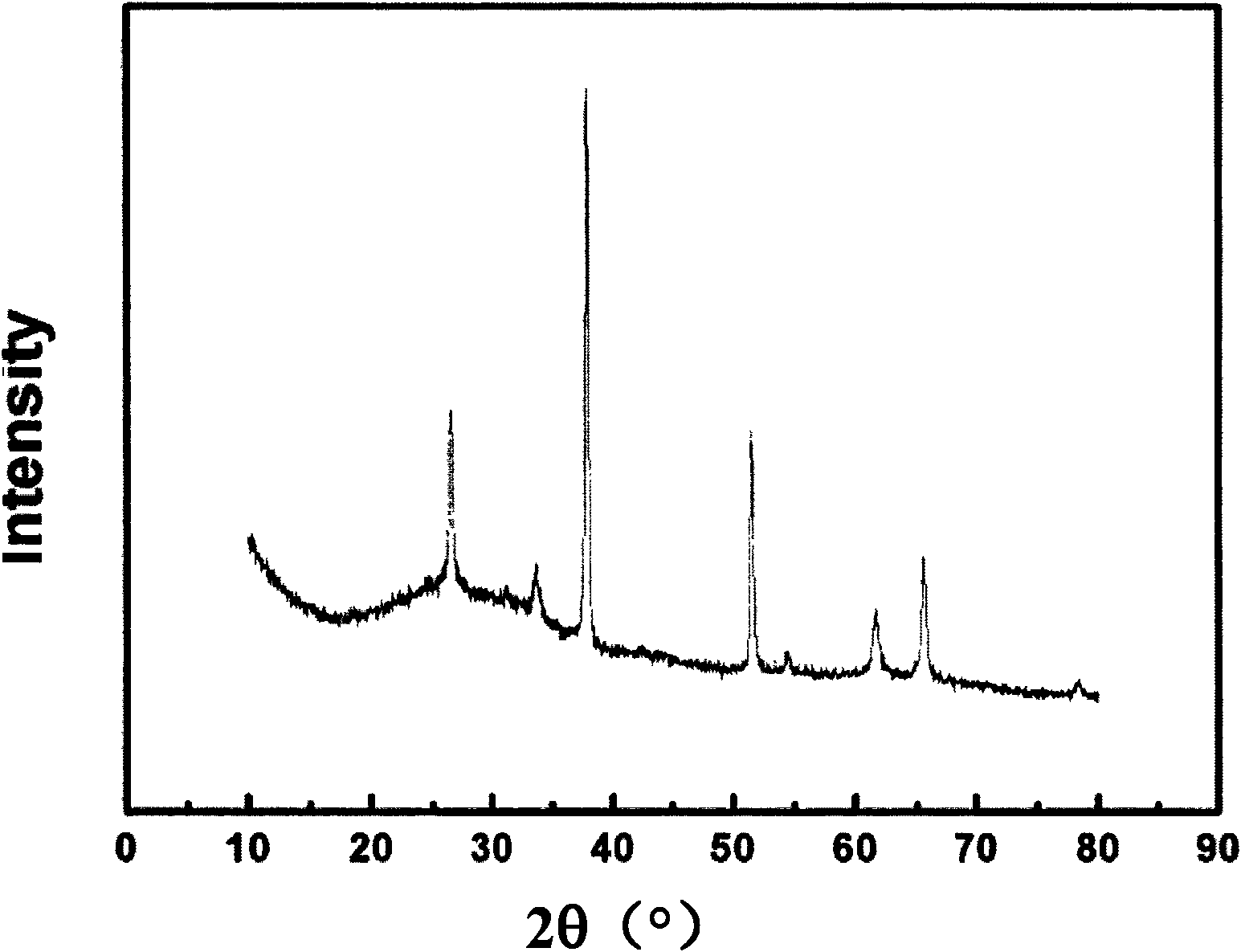

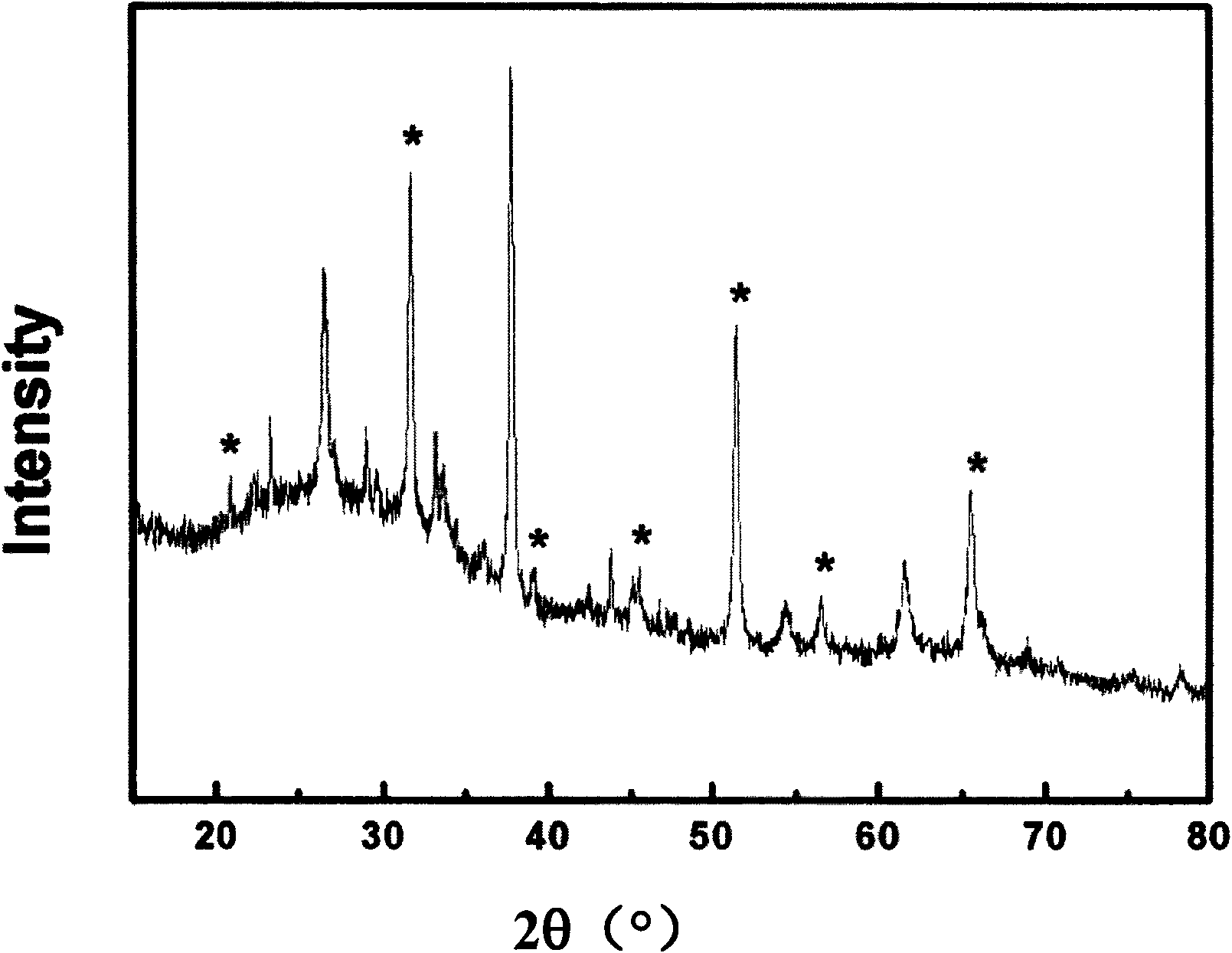

[0030] Step 1, preparation of titanium dioxide nanorod arrays with rutile structure:

[0031] At room temperature, add deionized water, concentrated hydrochloric acid and tetrabutyl titanate to the polytetrafluoroethylene lining of the hydrothermal kettle according to the volume ratio of 30:30:1, and mix well to prepare a titanium ion solution , the clean fluorine-doped tin dioxide conductive glass is completely immersed in the titanium ion solution, and then the polytetrafluoroethylene lining is placed in a hydrothermal kettle for sealing; the hydrothermal kettle is placed in an oven and heated to 150°C, heat preservation for 6h, take out the hydrothermal kettle, cool naturally, and obtain a titanium dioxide nanorod array with a rutile structure on the fluorine-doped tin dioxide conductive glass;

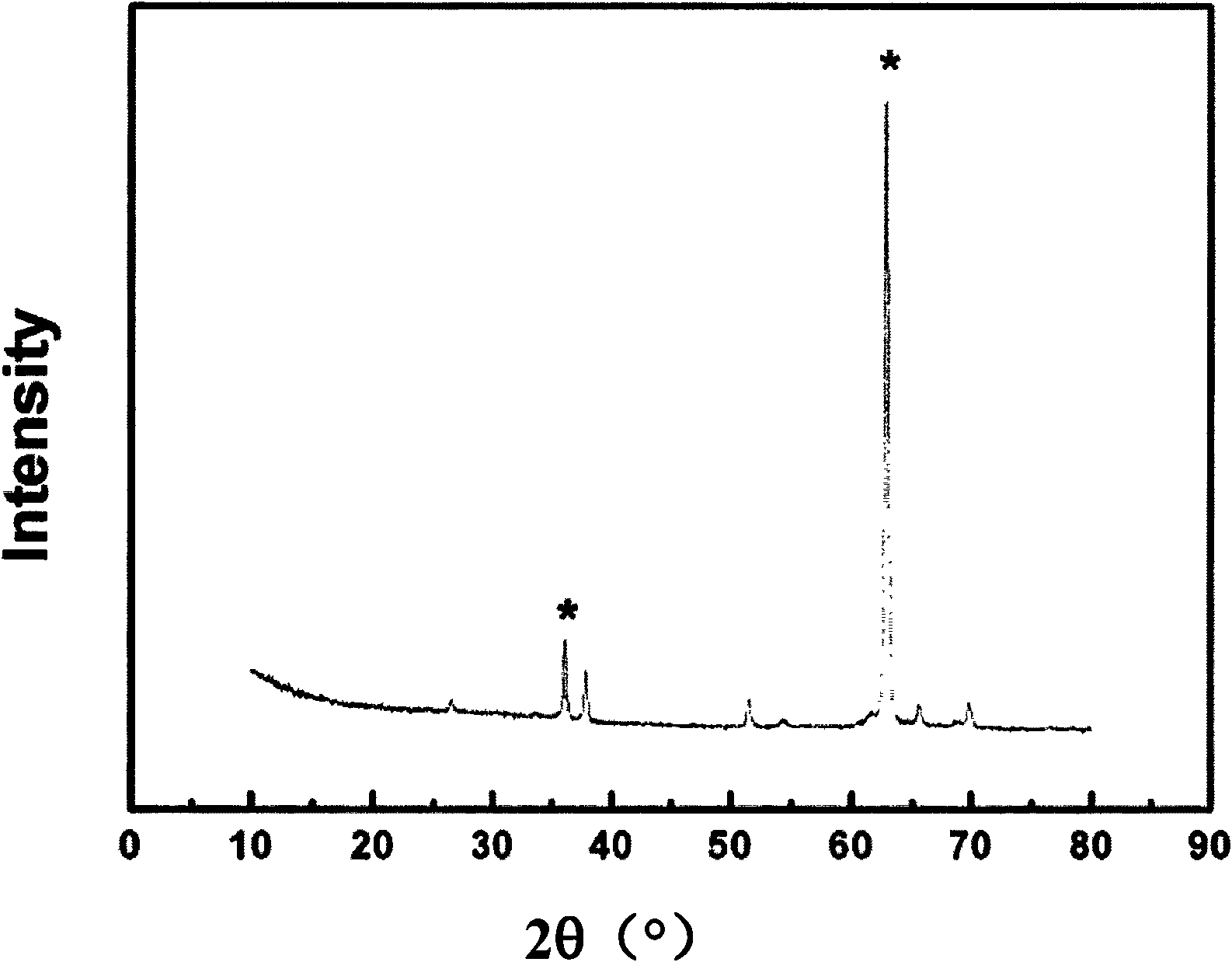

[0032] Step 2, preparation of tetragonal barium titanate nanorod arrays:

[0033]The fluorine-doped tin dioxide conductive glass grown in the titanium dioxide nanorod array with t...

Embodiment 2

[0036] Step 1, preparation of titanium dioxide nanorod arrays with rutile structure:

[0037] At room temperature, add deionized water, concentrated hydrochloric acid and titanium tetrachloride respectively in the polytetrafluoroethylene lining of the hydrothermal kettle according to the volume ratio of 30:30:0.5, and mix well to prepare a titanium ion solution. The clean fluorine-doped tin dioxide conductive glass is completely immersed in the titanium ion solution, and then the polytetrafluoroethylene lining is placed in a hydrothermal kettle for sealing; the hydrothermal kettle is placed in an oven, and the temperature is raised to 180 ℃, keep warm for 2h, take out the hydrothermal kettle, cool naturally, and obtain a titanium dioxide nanorod array with a rutile structure on the fluorine-doped tin dioxide conductive glass;

[0038] Step 2, preparation of tetragonal barium titanate nanorod arrays:

[0039] The fluorine-doped tin dioxide conductive glass grown in the titaniu...

Embodiment 3

[0042] Step 1, preparation of titanium dioxide nanorod arrays with rutile structure:

[0043] At room temperature, add deionized water, concentrated hydrochloric acid and titanium isopropoxide respectively in the polytetrafluoroethylene lining of the hydrothermal kettle according to the volume ratio of 20:40:1, and mix them uniformly to prepare a titanium ion solution. The clean fluorine-doped tin dioxide conductive glass is completely immersed in the titanium ion solution, and then the polytetrafluoroethylene lining is placed in a hydrothermal kettle for sealing; the hydrothermal kettle is placed in an oven, and the temperature is raised to 200 ℃, keep warm for 1h, take out the hydrothermal kettle, cool naturally, and obtain a titanium dioxide nanorod array with a rutile structure on the fluorine-doped tin dioxide conductive glass;

[0044] Step 2, preparation of tetragonal barium titanate nanorod arrays:

[0045] The fluorine-doped tin dioxide conductive glass grown in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com