Doped and modified barium strontium calcium titanate heat-release pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and barium strontium titanate, which is applied in the field of barium strontium titanate calcium pyroelectric ceramic materials and its preparation, can solve the problems of dielectric and pyroelectric performance degradation, and achieve a large dielectric constant, The effect of simple process and high pyroelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

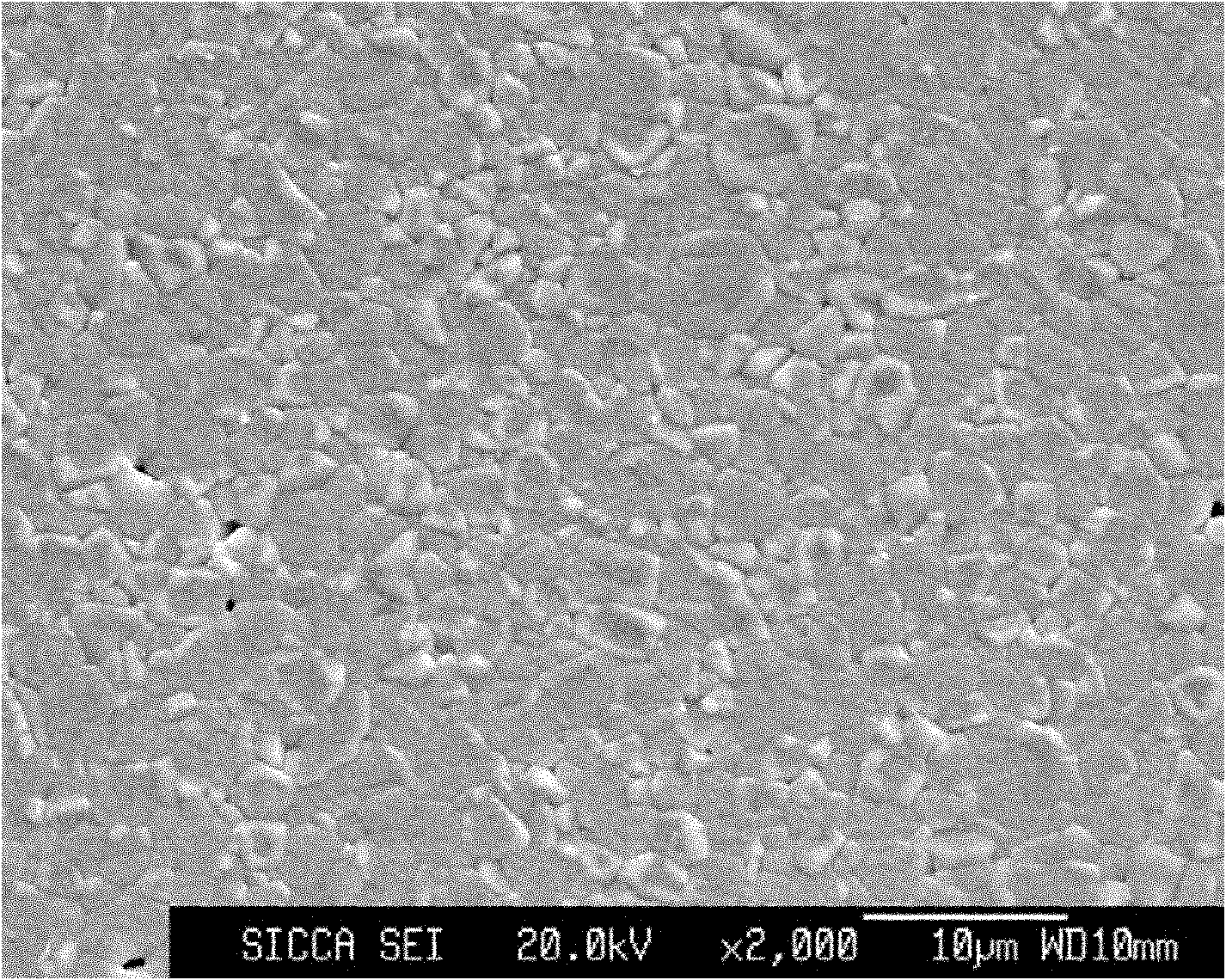

[0033] First, according to the general formula (Ba 0.6 Sr 0.3 Ca 0.1 ) 0.993 Y 0.007 Ti 0.999 mn 0.001 o 3 Weigh out the stoichiometric BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 , Y 2 o 3 and MnCO 3 For each powder, use a wet ball milling process to mix all the powders evenly; the mass ratio of ball milling material to ball milling medium and deionized water is 1:1.5:1.2, and the ball milling time is 18 hours. The ball milling medium is steel ball, zirconium ball or agate ball.

[0034]Dry, add the deionized water of 10% weight of total powder, briquette, synthesize under atmospheric atmosphere, synthesis temperature is 1100 ℃, and holding time is 2 hours, obtains composition as (Ba 0.6 Sr 0.3 Ca 0.1 ) 0.993 Y 0.007 Ti 0.999 mn 0.001 o 3 The powder; pulverize, cross 40 mesh sieves, and then use the wet ball milling process to mix the powder evenly; the mass ratio of ball milling material to ball milling medium and deionized water is 1: 1.8: 0.7, and the ball milling...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is only: according to the general formula (Ba 0.6 Sr 0.3 Ca 0.1 ) 0.991 Y 0.009 Ti 0.999 mn 0.001 o 3 Weigh out the stoichiometric BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 , Y 2 o 3 and MnCO 3 Each powder.

[0044] The remaining content of this embodiment is the same as that described in Example 1, and the performance test results of the prepared samples are shown in Table 1.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is only: according to the general formula (Ba 0.6 Sr 0.3 Ca 0.1 ) 0.995 Y 0.005 Ti 0.999 mn 0.001 o 3 Weigh out the stoichiometric BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 , Y 2 o 3 and MnCO 3 Each powder.

[0047] The remaining content of this embodiment is the same as that described in Example 1, and the performance test results of the prepared samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Pyroelectric coefficient | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com