Wet rubbing fastness promoting agent and preparation method thereof

A technology for wet rubbing fastness and improving agent, which is applied in the field of textile auxiliaries and their preparation, can solve the problems of affecting color index, poor hand feeling, increasing processing cost, etc. The effect of rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

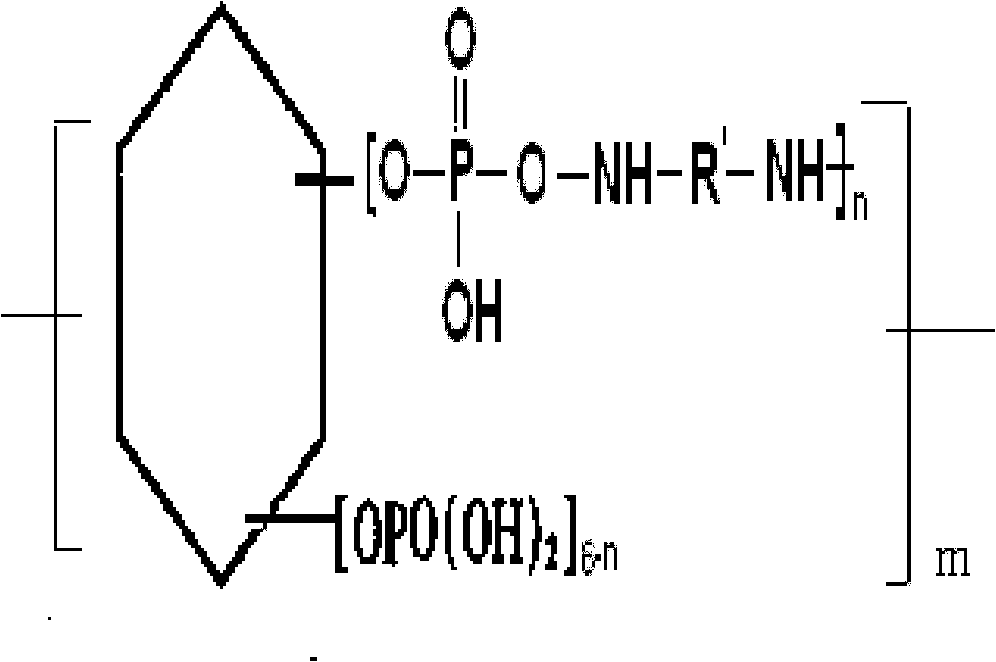

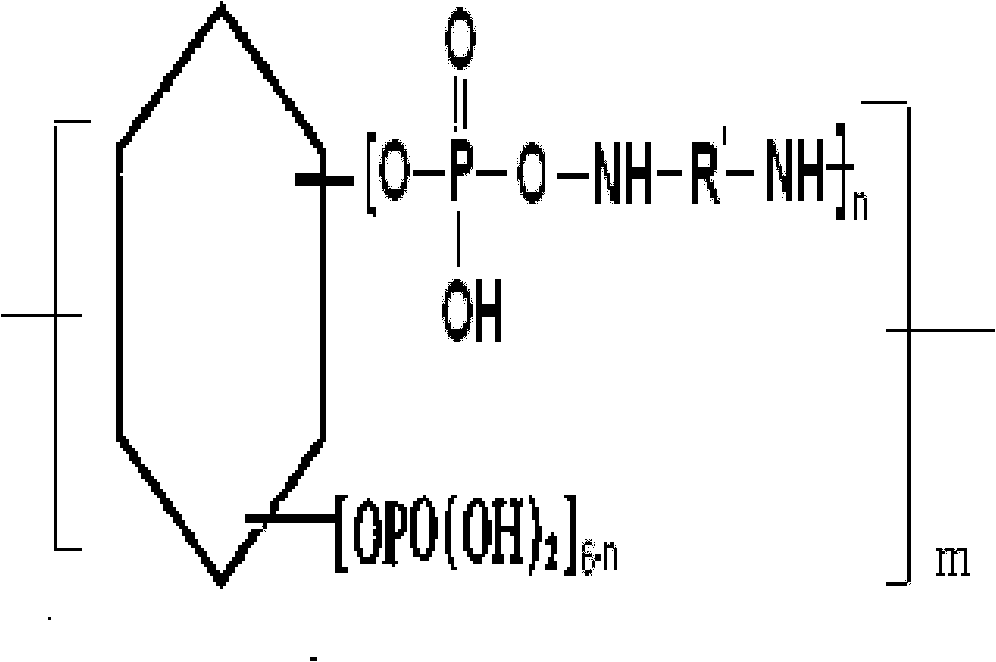

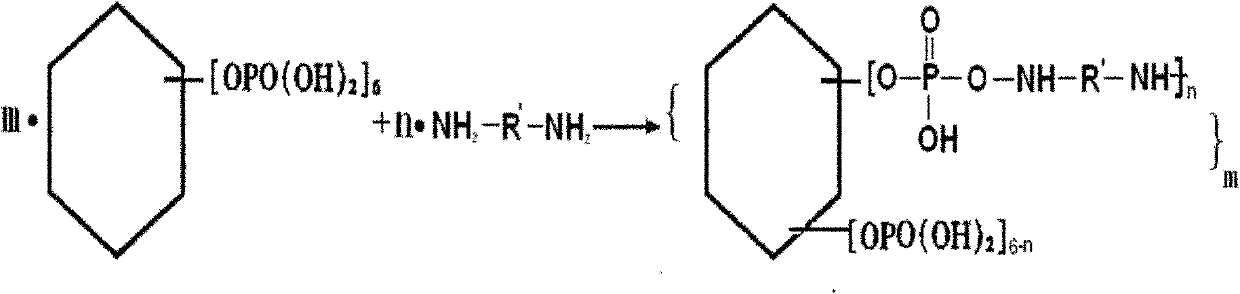

Method used

Image

Examples

Embodiment 1

[0023] The effect of the ratio on the appearance and performance of the synthetic enhancer:

[0024] Add ethylenediamine in the aqueous solution of cyclohexyl hexaphosphate (aqueous solution of cyclohexyl hexaphosphate with a concentration of 50% and a purity of 98%), heat up to 40°C, react for 30 minutes and then cool to room temperature (25 ℃), then,

[0025] The test results are shown in Table 1:

[0026] Table 1 Effect of raw material ratio on performance of synthetic enhancer

[0027]

[0028] It can be seen from Table 1 that with the increase of the proportion of the ethylenediamine component, the appearance of the synthetic enhancer gradually changes, from colorless to yellow, and at the same time gradually changes from transparent to opaque; the viscosity of the enhancer gradually increases; The pH of the synthetic enhancer transitions from acidic to weakly alkaline, and at the same time, the stability of the synthetic enhancer gradually decreases. In summary, th...

Embodiment 2

[0030] Influence of synthesis temperature on performance of enhancer

[0031] Add ethylenediamine to the aqueous solution of cyclohexyl hexaphosphate, raise the temperature, react for 30 minutes and then cool to room temperature (25°C). The molar ratio of cyclohexyl hexaphosphate to ethylenediamine is 1:3 .

[0032] The test results are shown in Table 2

[0033] Table 2 Effect of synthesis temperature on the performance of enhancer

[0034]

[0035]

[0036] It can be seen from Table 2 that under the conditions of determining the proportion and reaction time, the reaction temperature has little influence on the viscosity, pH value and stability of the synthetic enhancer, but has a greater impact on the appearance of the enhancer. As the temperature rises, the color of the enhancer gradually deepens. The color deepening of the lifting agent is not conducive to the fixation of dyed yarn or fabric, especially for light-colored fabrics, the color of the lifting agent will...

Embodiment 3

[0038] The effect of reaction time on the performance of synthetic enhancers.

[0039] Add ethylenediamine to the aqueous solution of cyclohexyl hexaphosphate, raise the temperature to 40°C, and after a period of reaction, cool to room temperature (25°C). The molar ratio of cyclohexanehexaphosphate to ethylenediamine It is 1:3.

[0040] The test results are shown in Table 3

[0041] Table 3 Effect of reaction time on performance of enhancer

[0042]

[0043] It can be seen from Table 3 that: under the determined proportioning and reaction temperature, only when the reaction time is 15min, the viscosity of the synthetic enhancer is low, indicating that the reaction is not sufficient; when the reaction time increases to 30min or longer, the synthetic enhancer The appearance, viscosity, pH value, and stability of the agent did not change much, indicating that the reaction time had little effect on the performance of the enhancer. From the perspective of energy saving, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com