Separation preparation method for high-purity agarotetrol and 4'-methoxy agarotetrol

A kind of methoxy agarwood tetraol, agarwood tetraol technology, applied in the direction of organic chemistry, etc., to achieve the effect of improved separation efficiency, mild separation environment, and large separation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The agarwood is crushed into coarse powder, 100 g of coarse powder is added to 1000 mL of 95% ethanol, and extracted under reflux for 3 hours, 3 hours each time, filtered, and rotary evaporated to dryness to obtain a brown-black extract for later use.

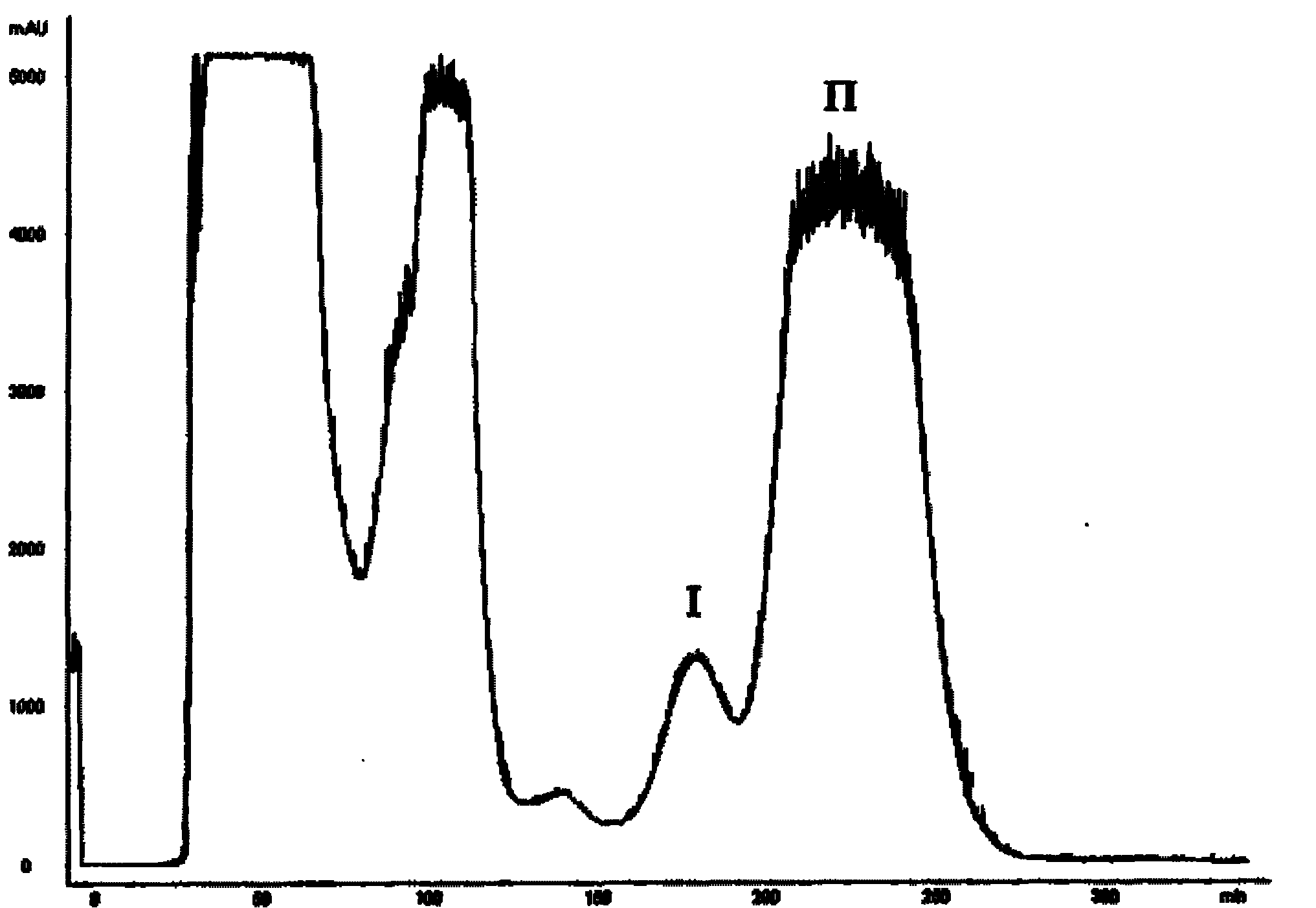

[0037] Select n-heptane-chloroform-methanol-water from the solvent system on a semi-preparative high-speed countercurrent chromatograph to separate and prepare agarwood tetraol and 4'-methoxy linalane tetraol. Place the above-mentioned solvent components in a separatory funnel at a volume ratio of 0.5:3.5:2.8:2.2, shake well, and stand still for layering. After equilibrating for a period of time, the upper phase (stationary phase) and the lower phase (mobile phase) are separated, and the experimental condition temperature is 20°C. Use TBE-300A high-speed countercurrent chromatograph, equipped with KTA purifier P-900 pump, UV detector, HX-1050 thermostatic circulator. Weigh 80 mg of the sample and dissolve it in 10 mL of m...

Embodiment 2

[0039] The agarwood is crushed into coarse powder, 100 g of coarse powder is added to 1000 mL of 95% ethanol, and extracted under reflux for 3 hours, 3 hours each time, filtered, and rotary evaporated to dryness to obtain a brown-black extract for later use.

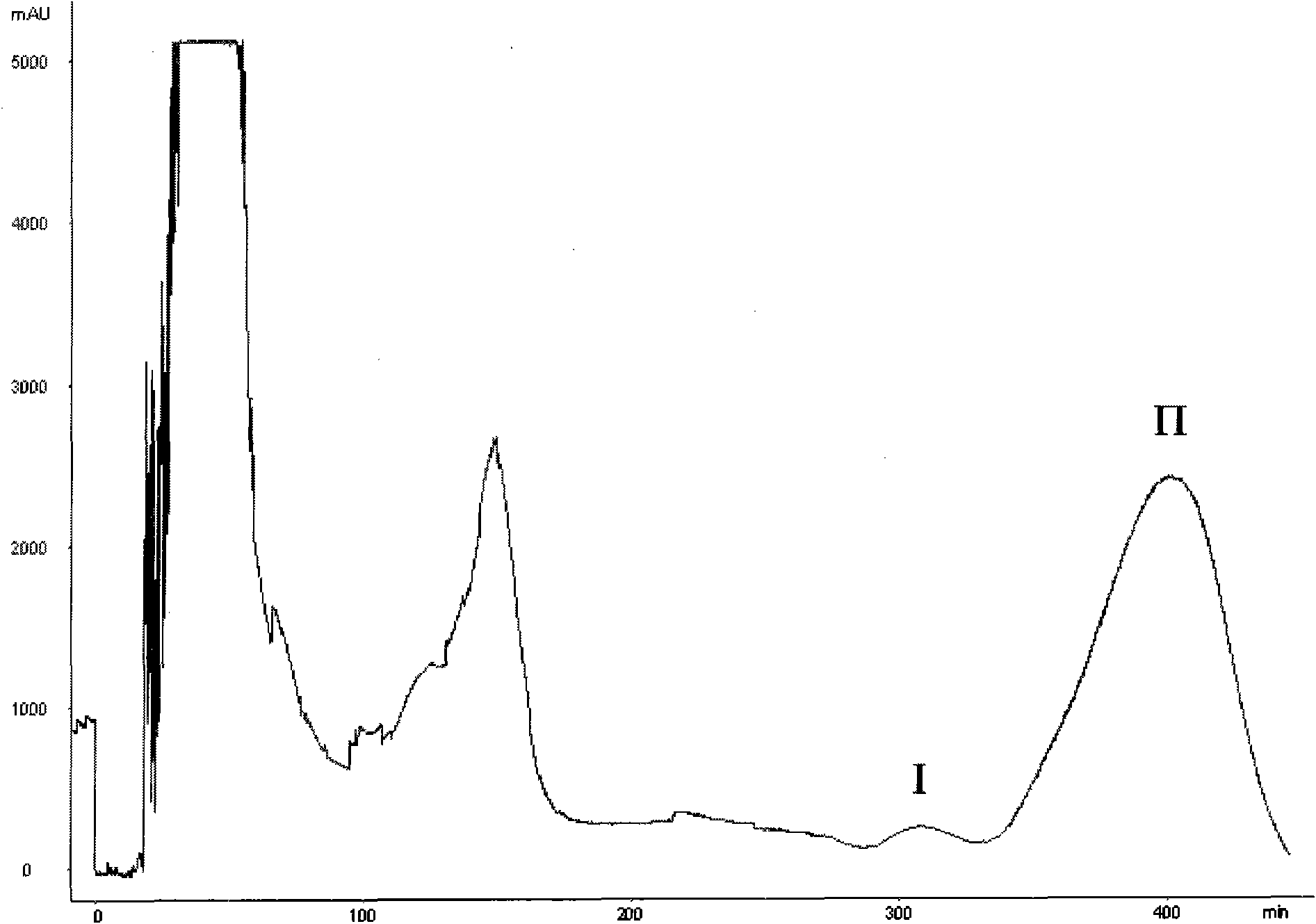

[0040] Select n-hexane-chloroform-methanol-water from the solvent system to separate and prepare agarwood tetraol and 4'-methoxy agarwood tetraol on a semi-preparative high-speed countercurrent chromatograph. Place the above-mentioned solvent components in a separatory funnel at a volume ratio of 0.3:3.7:2.6:2.4, shake well, and stand still for layering. After equilibrating for a period of time, the upper phase (stationary phase) and the lower phase (mobile phase) are separated, and the experimental condition temperature is 20°C. Use TBE-300A high-speed countercurrent chromatograph, equipped with KTA purifier P-900 pump, UV detector, HX-1050 thermostatic circulator. Weigh 30 mg of the sample and dissolve it in 10 mL of mo...

Embodiment 3

[0042] The agarwood is pulverized into coarse powder, 100 g of coarse powder is added to 1000 mL of 95% ethanol, and extracted under reflux for 3 hours, 3 hours each time, filtered, and rotary evaporated to dryness to obtain a brown-black extract for later use.

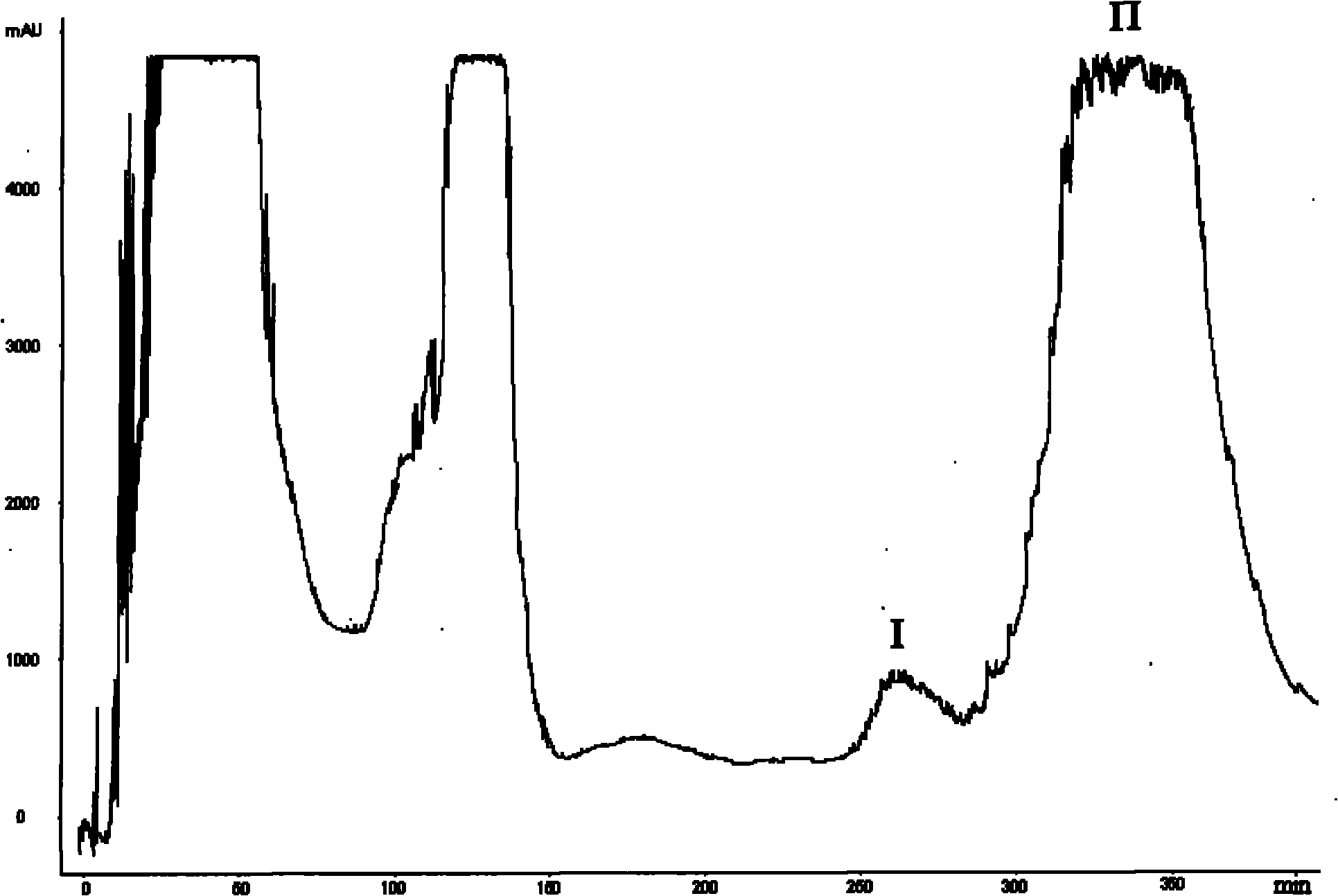

[0043] Select carbon tetrachloride-chloroform-acetone-water from the solvent system to separate and prepare agarwood tetraol and 4'-methoxy agarwood tetraol on a semi-preparative high-speed countercurrent chromatograph. The above-mentioned solvent components are arranged in a separatory funnel at a volume ratio of 0.2:3.8:3.2:1.8, shake well and stand still for layering. After equilibrating for a period of time, the upper phase (stationary phase) and the lower phase (mobile phase) are separated, and the experimental condition temperature is 20°C. Use TBE-300A high-speed countercurrent chromatograph, equipped with KTA purifier P-900 pump, UV detector, HX-1050 thermostatic circulator. Weigh 150 mg of the sample and disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com