Environmentally-friendly flexible epoxy resin grouting material

A technology of epoxy resin grouting and epoxy resin, which is applied in the direction of building insulation materials, building components, sea area engineering, etc., can solve the problems of detonation, high compressive strength, poor environmental protection performance, etc., achieve the reduction of liquid viscosity, improve Improvement of air environment and work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ratio of raw materials of this embodiment is:

[0020] CYD-128 type epoxy resin 100 parts by weight

[0021] Butyl glycidyl ether 60 parts by weight

[0022] Amino-terminated polyether D400 60 parts by weight

[0023] Modified fatty amine curing agent 8 parts by weight

[0024] 2,4,6-tris(dimethylaminomethyl)phenol 4 parts by weight

[0025] 5 parts by weight of γ-aminopropyltriethoxysilane

[0026] Mix the above CYD-128 type epoxy resin and butyl glycidyl ether into A liquid, amino-terminated polyether D400, modified fatty amine curing agent, 2,4,6-tris(dimethylaminomethyl)phenol and γ -Aminopropyltriethoxysilane mixed into liquid B. Mix liquid A and liquid B evenly before use.

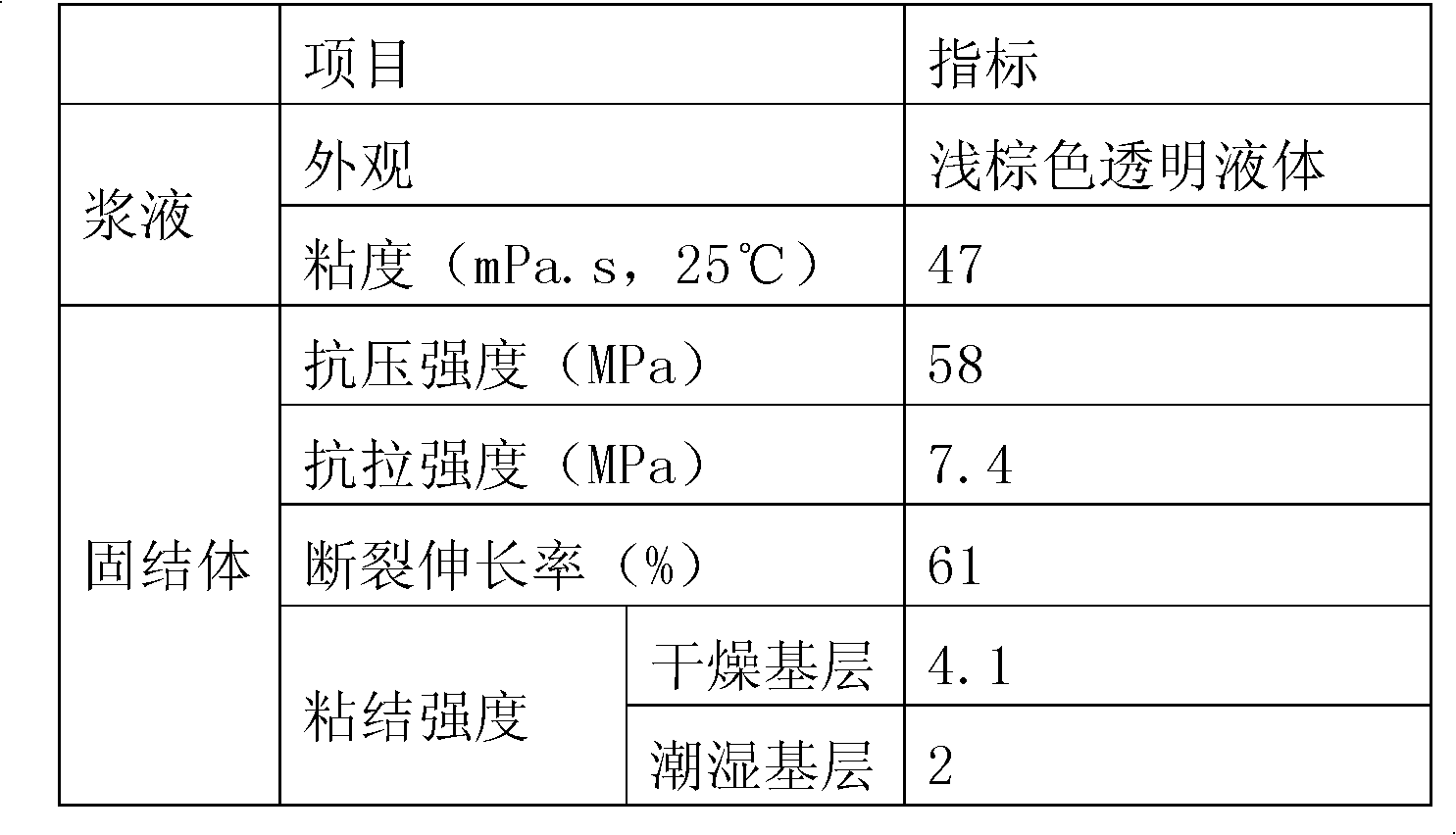

[0027] The product technical indicators obtained in the above implementation cases are as follows:

[0028]

Embodiment 2

[0030] The raw material ratio of this example is:

[0031] E-51 type epoxy resin 100 parts by weight

[0032] 80 parts by weight of ethylene glycol diglycidyl ether

[0033] Amino-terminated polyether D2000 60 parts by weight

[0034] 14 parts by weight of modified fatty amine curing agent

[0035] 2,4,6-tris(dimethylaminomethyl)phenol 3 parts by weight

[0036] γ-glycidoxypropyltrimethoxysilane 6 parts by weight

[0037] Mix the above-mentioned E-51 type epoxy resin, ethylene glycol diglycidyl ether and γ-glycidoxypropyl trimethoxysilane into liquid A, mix the above-mentioned amino-terminated polyether D2000, modified fatty amine curing agent , 2,4,6-tris(dimethylaminomethyl)phenol were mixed into liquid B. Mix liquid A and liquid B evenly before use.

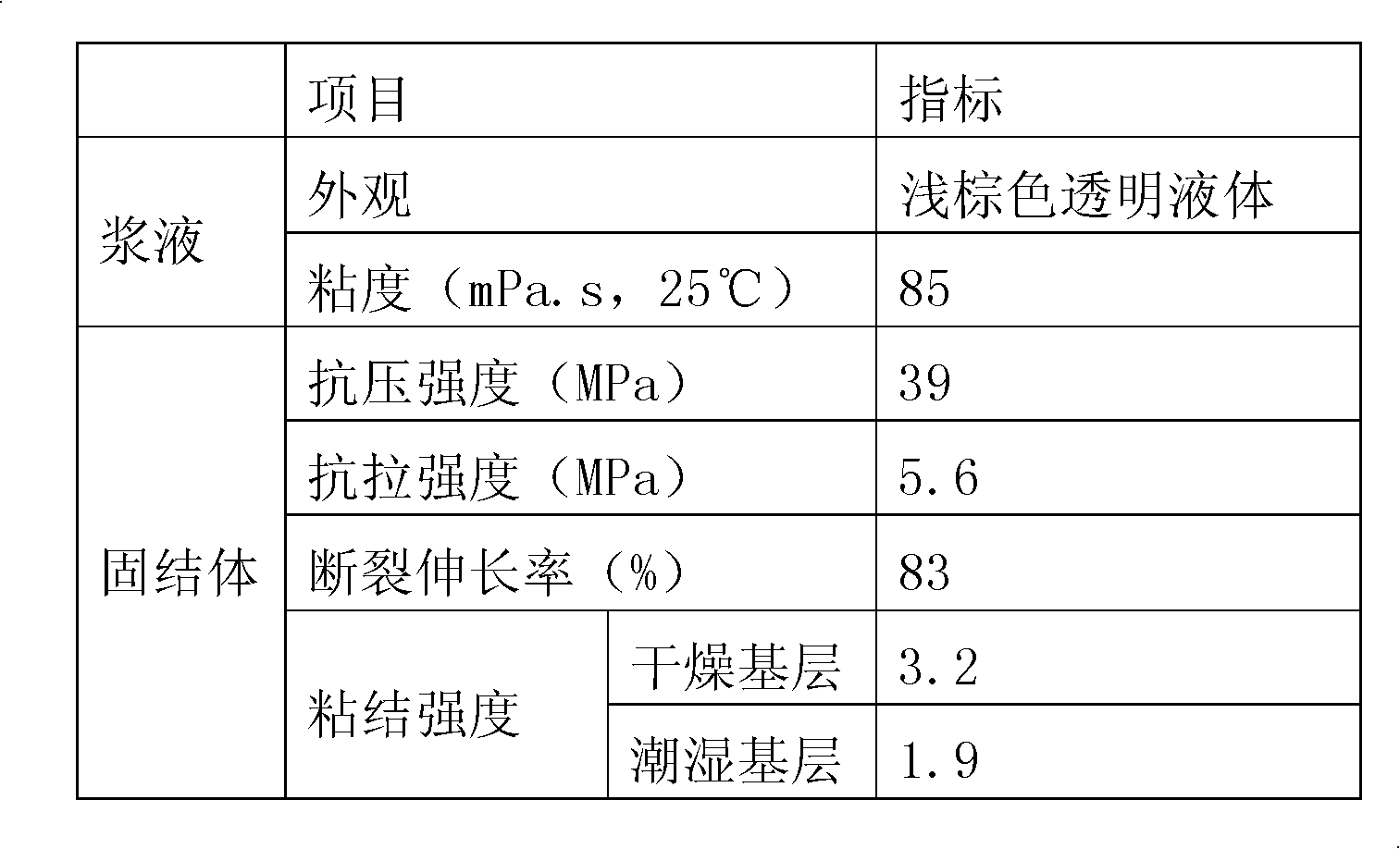

[0038] The product technical indicators obtained in the above implementation cases are as follows:

[0039]

Embodiment 3

[0041] The raw material ratio of this example is:

[0042] F51 type epoxy resin 100 parts by weight

[0043] Butanediol diglycidyl ether 60 parts by weight

[0044]Amino-terminated polyether D400 50 parts by weight

[0045] 651 curing agent 18 parts by weight

[0046] 2,4,6-Tris(dimethylaminomethyl)phenol 2 parts by weight

[0047] γ-glycidoxypropyltrimethoxysilane 6 parts by weight

[0048] The above-mentioned F51 type epoxy resin, butanediol diglycidyl ether and γ-glycidoxypropyl trimethoxysilane are mixed into A liquid, the above-mentioned amino-terminated polyether D400, 651 curing agent and 2,4, 6-Tris(dimethylaminomethyl)phenol is mixed into B liquid. Mix A and B evenly before use.

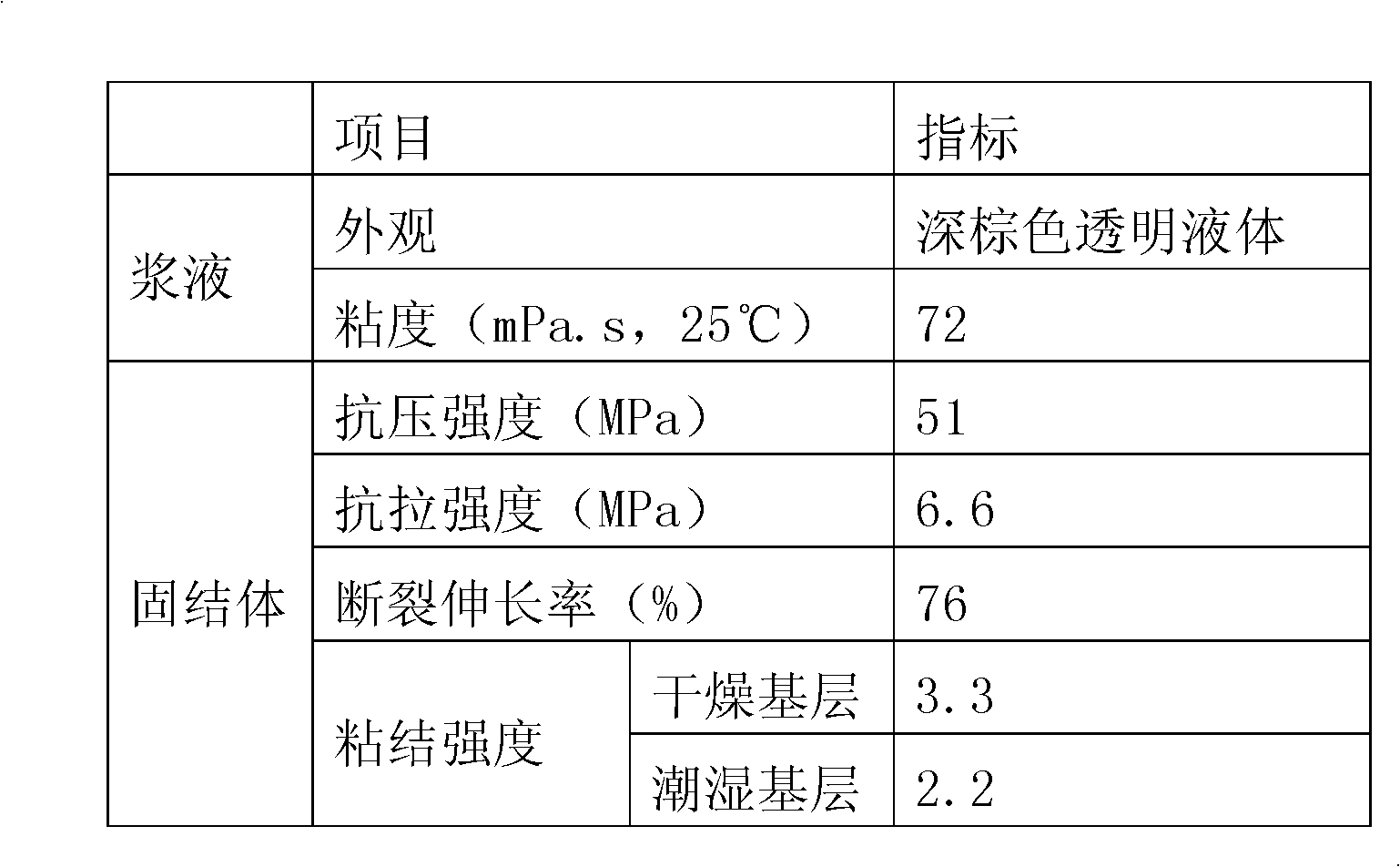

[0049] The product technical indicators obtained from the above implementation cases are as follows:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com