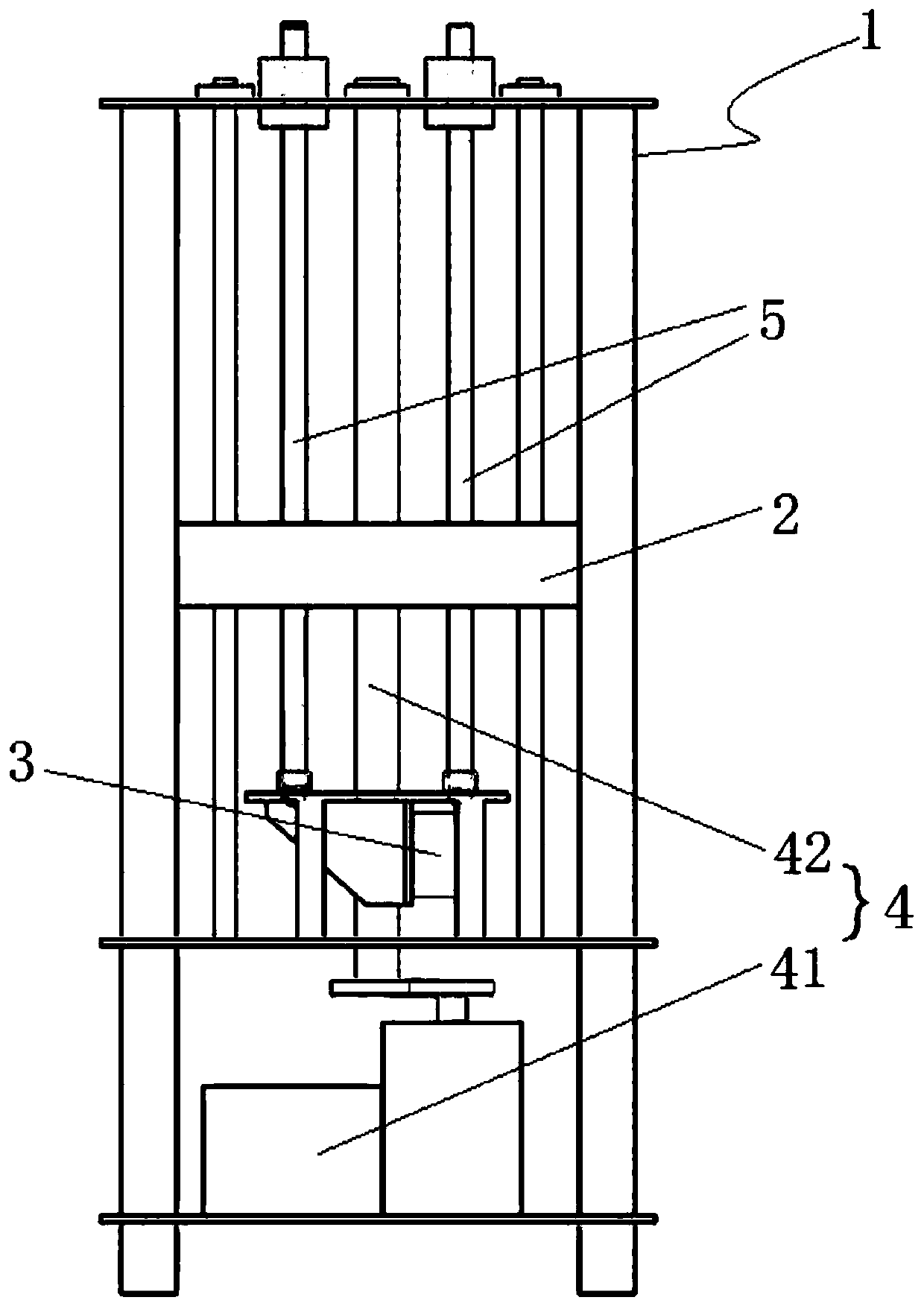

Zone melting-directional solidification furnace and semiconductor thermoelectric material synthesis method

A technology of directional solidification furnace and thermoelectric materials, which is applied in self-regional melting method, manufacturing/processing of thermoelectric devices, polycrystalline material growth, etc., can solve the problems of difficult realization of high energy density heat source, large temperature difference, low efficiency, etc., to achieve Easy to query and call, wide range of performance adjustment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

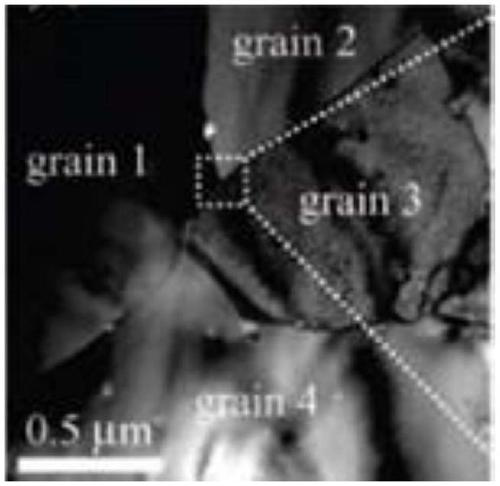

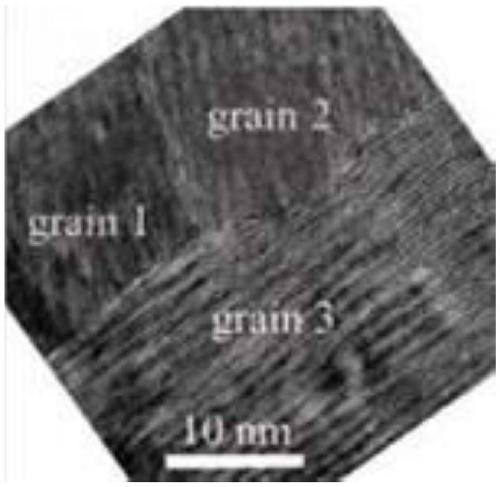

[0051] The synthesis method of bismuth telluride-based thermoelectric material inlaid with N-type nano crystal grains comprises the following steps:

[0052] (1) Place the N bismuth telluride-based thermoelectric material sintered by the fusion mixing method in a vacuum-tight quartz tube in a zone melting-directional solidification furnace, move the columnar heating ring to the bottom of the quartz tube, and set the heating temperature to 1073K;

[0053] (2) After the temperature reaches 1073K, stabilize for 30 minutes, start the frequency conversion vibrator, and set the frequency to 150Hz;

[0054] (3) Set the lifting speed of the heating body to 0.15 mm / min, start the heating body lifting device, and slowly lift the heating body;

[0055] (4) When the top material in the quartz tube is solidified through zone melting, stop the heating body lifting device;

[0056] (5) Adjust the set temperature to 673K. After stabilization, set the descending speed of the heating body to 4...

specific Embodiment 2

[0059] The synthesis method of bismuth telluride-based thermoelectric material inlaid with P-type nano crystal grains comprises the following steps:

[0060] (1) Place the P bismuth telluride-based thermoelectric material sintered by the fusion mixing method in the vacuum-tight quartz tube in a zone melting-directional solidification furnace, move the columnar heating ring to the bottom of the quartz tube, and set the heating temperature to 973K;

[0061] (2) After the temperature reaches 973K, stabilize for 30 minutes, start the frequency conversion vibrator, and set the frequency to 180Hz;

[0062] (3) Set the lifting speed of the heating body to 0.35 mm / min, start the heating body lifting device, and slowly lift the heating body;

[0063] (4) When the top material in the quartz tube is solidified through zone melting, stop the heating body lifting device;

[0064] (5) Adjust the set temperature to 623K. After stabilization, set the heating body to drop at a speed of 3.5 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com