A kind of fiber-reinforced functional adhesive tape and its preparation method and product

A fiber reinforced and functional technology, applied in the field of fiber reinforced functional tape and its preparation, can solve the problems of reducing the resource utilization rate and economic benefit of carbon fiber composite materials, large "bridge" area, increasing defect area, etc. Application prospect, large performance adjustment range, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

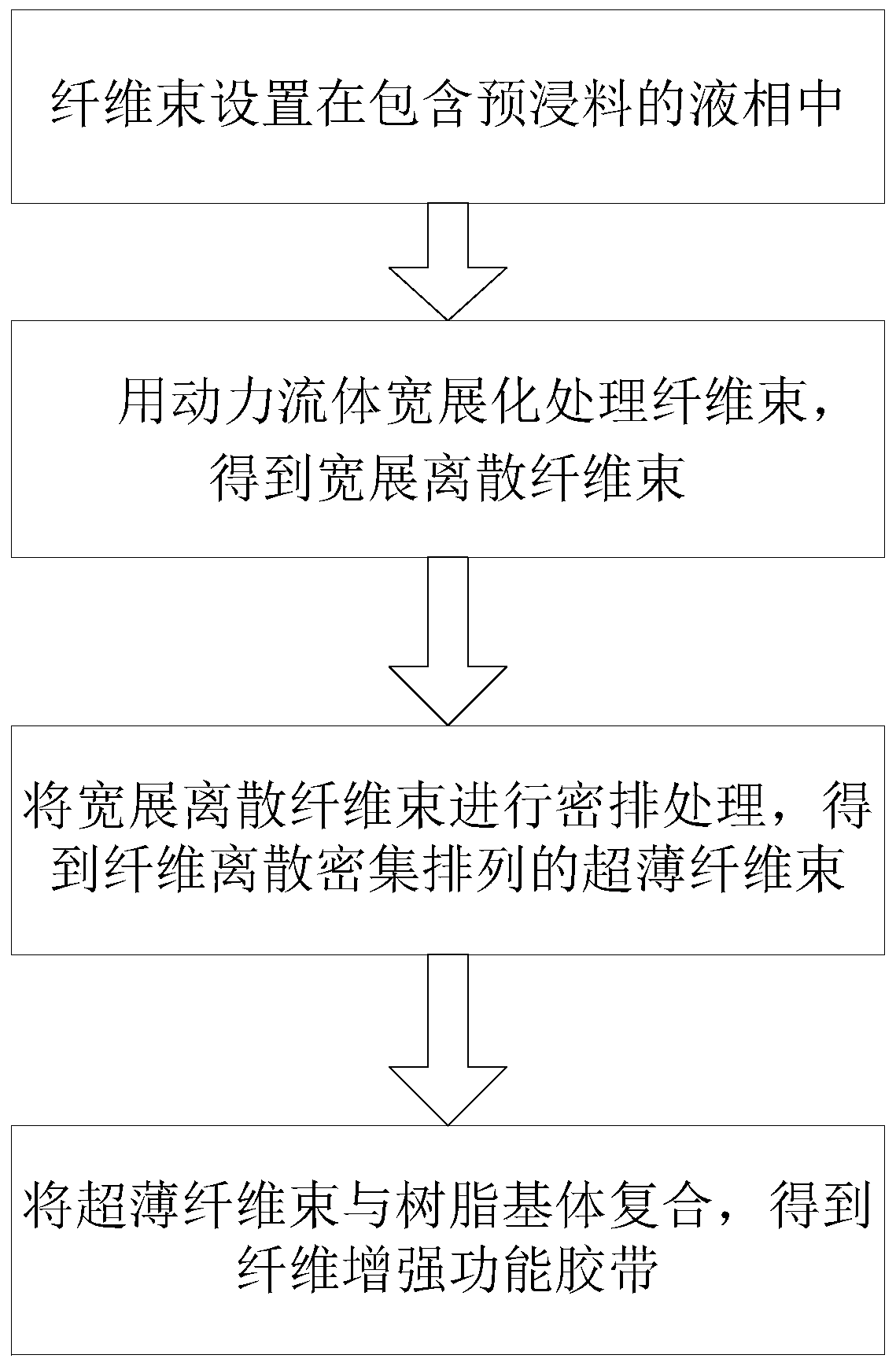

[0054] Embodiment 1 preparation method and preparation device

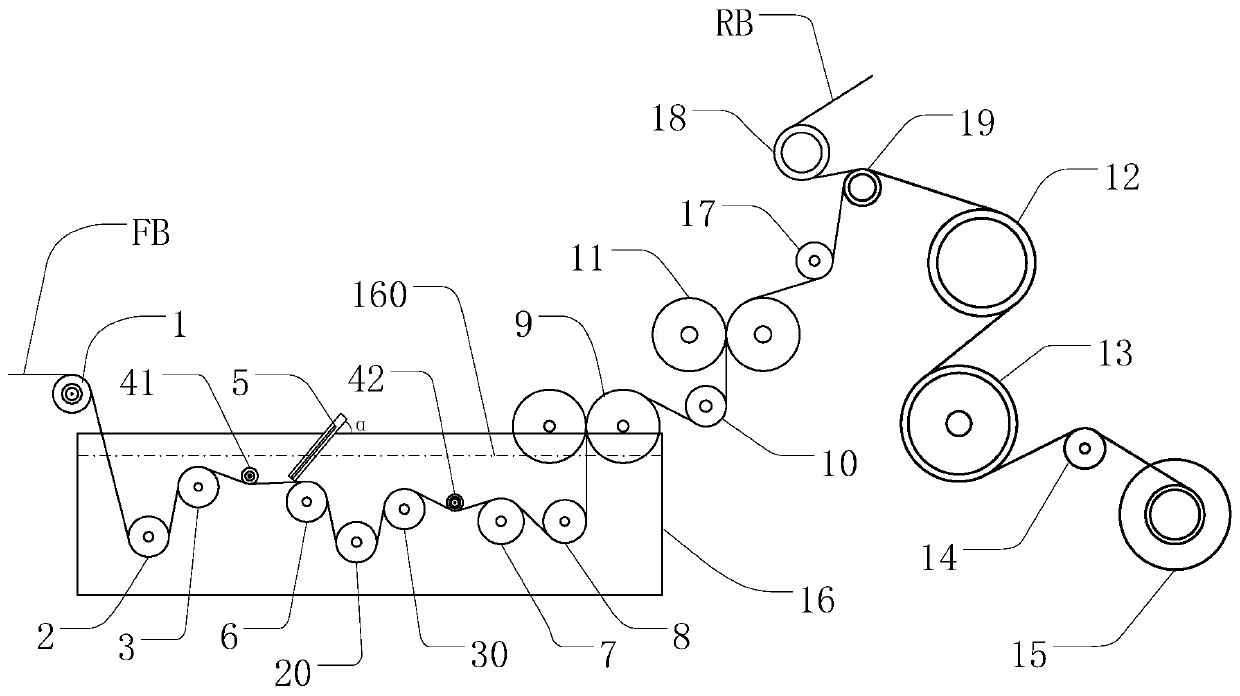

[0055] Embodiment 1 is combined with attached figure 2 and 3 , the preparation process of the fiber-reinforced functional adhesive tape disclosed in the present invention will be further described in detail.

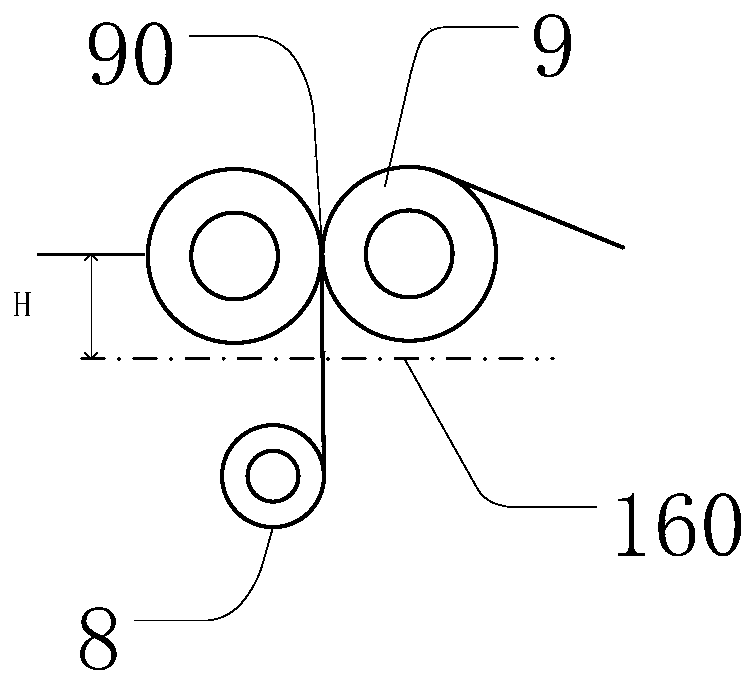

[0056] The device in this embodiment is installed along the horizontal direction, and the cuboid box 16 is installed horizontally, and its upper part is open. The solution containing prepreg is set in the box 16. The liquid level 160 is shown by the dotted line in the figure, and the first guide wheel 1 is set. Above the box body 16 side, the first traction wheel 2 and the first auxiliary wheel 3 are sequentially arranged in the box body 16, and the two cooperate with each other to provide the first power for the fiber bundle FB to advance, and the fiber bundle FB is under the action of the first power into solution;

[0057] The first tension sensor 41 and the loose yarn component 5 are set, and then th...

Embodiment 2

[0063] Embodiment 2 Ultra-thin carbon fiber prepreg tape unidirectional laminate

[0064]Use the device disclosed in Example 1 of the present invention to prepare an ultra-thin carbon fiber prepreg tape, prepare a unidirectional laminate with carbon fiber ultrathin than the impregnated tape and PA6 resin, wherein the mass fraction of carbon fiber is 60%, and the mass fraction of PA6 resin is 40%. The thickness of the carbon fiber prepreg tape is 0.02mm, and the thickness of the unidirectional laminate is 1mm. The performance test results show that the tensile strength of the laminate is 2200MPa, the tensile modulus is 150GPa, the compressive strength is 1600MPa, the compressive modulus is 165GPa, the open-hole tensile strength is 520MPa, the open-hole compressive strength is 430MPa, and the compressive strength after impact is 420MPa. Compared with a unidirectional laminate with a thickness of 1mm prepared by conventional 0.2mm thick carbon fiber prepreg tape and PA6 resin, th...

Embodiment 3 2

[0065] Embodiment 3 two-dimensional woven cloth

[0066] A 0.02 mm thick ultra-thin carbon fiber prepreg tape was woven in a two-dimensional orthogonal manner to prepare a two-dimensional woven fabric, which was then laminated into a quasi-isotropic laminate with a thickness of 1 mm.

[0067] After testing, the fiber axial tensile strength of the quasi-isotropic laminate is 1020MPa, the compressive strength is 870MPa, and the tensile modulus is 130GPa; the tensile strength perpendicular to the fiber axial direction is 980MPa, the compressive strength is 860MPa, and the tensile modulus The volume is 130GPa. Compared with a laminate of the same thickness prepared by 0.2mm carbon fiber pre-taped woven cloth, the mechanical properties are all improved by more than 30%.

[0068] The quasi-isotropic laminate obtained by using the two-dimensional woven fabric of Example 3 has quasi-isotropy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com