Method for preparing S-(+)-3-methyl hydroxybutyrate through microbial transformation

A technology for the transformation of methyl hydroxybutyrate and microorganisms, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of cumbersome catalyst preparation and high cost, and achieve easy large-scale industrial production, simple operation, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Saccharomyces cerevisiae CGMCC No. 2266 strain was inoculated into the slant medium, and cultured at 30° C. for 4 to 6 days to prepare the bacterial cell slant. Use an inoculation needle to take an inoculation loop from the slant of the bacterium and inoculate it into a 250mL Erlenmeyer flask containing 100mL of liquid medium, and culture it at 30°C and 180r / min for 24h to obtain a seed solution. Inoculate 10 mL of seed solution (the inoculum size is 10% of the volume of the liquid medium) into a 250 mL Erlenmeyer flask containing 100 mL of liquid medium, cultivate it for 24 hours at 30° C. and 180 r / min to obtain a fermented liquid, and centrifuge the fermented liquid to obtain Enzyme cells.

[0028] The determination of the dry weight of the bacteria is to take a small part from the wet cells after centrifuging the fermentation broth and dry it at 120°C for 48 hours to a constant weight, measure the weight of the dry cells, and calculate the ratio of dry cells in the ...

Embodiment 2

[0036] Saccharomyces cerevisiae CGMCC No.2266 strain was inoculated into the slant medium, and cultured at 30° C. for 4 to 6 days to obtain the slant surface of the bacteria. Use an inoculation needle to take an inoculation loop from the slant of the bacterium and inoculate it into a 250mL Erlenmeyer flask containing 100mL of liquid medium, and culture it at 30°C and 180r / min for 24h to obtain a seed solution. The seed solution was inoculated in a 250mL Erlenmeyer flask containing 100mL of liquid medium with a 10% inoculation amount, cultivated at 30°C and 180r / min for 24 hours to obtain a fermentation broth, and the fermentation broth was centrifuged to obtain enzyme-containing bacterial cells. The dry weight of enzyme-containing bacterium cells contained in 1 liter of fermented liquid is 50 grams.

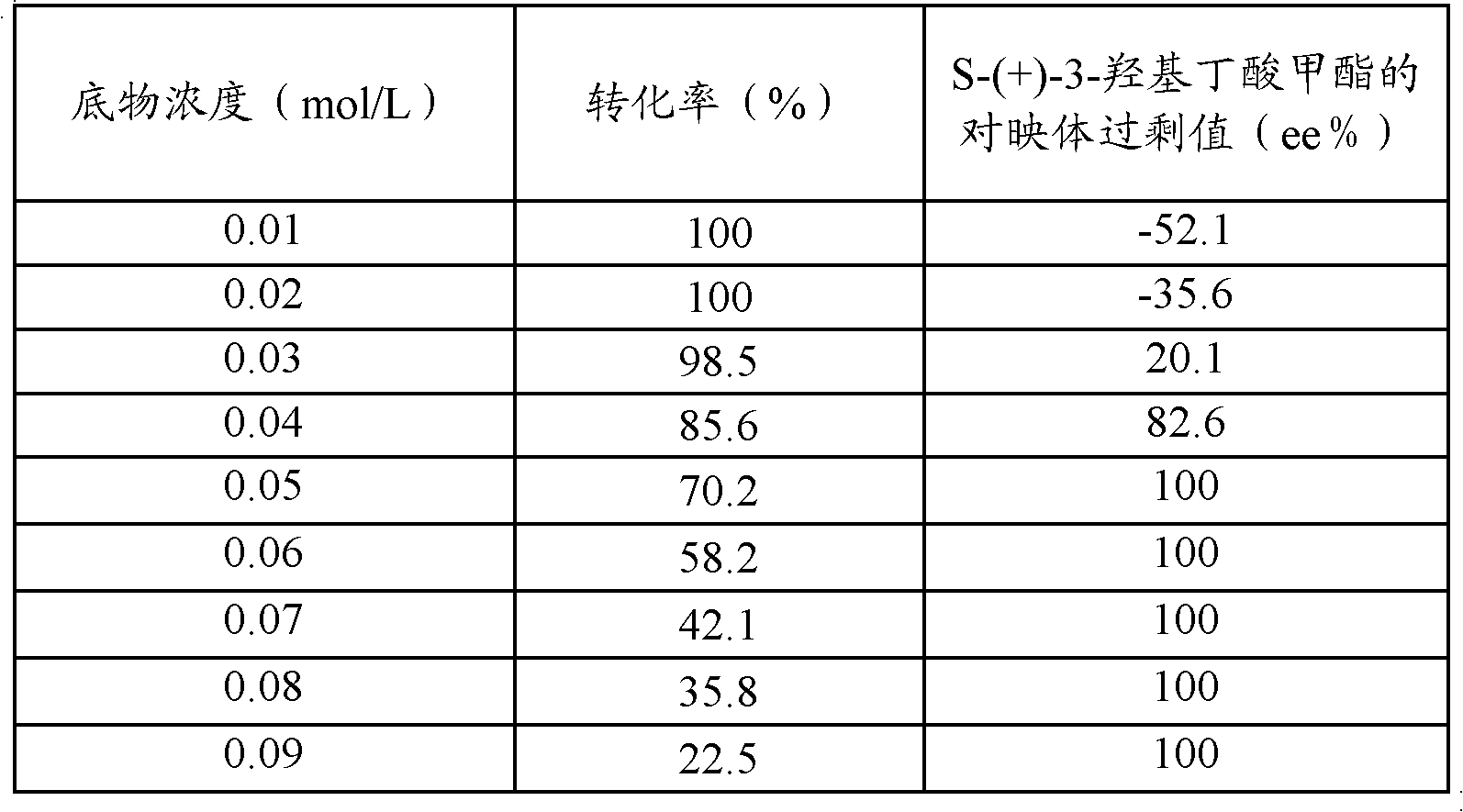

[0037] In five parts of Erlenmeyer flasks containing 100mL pH7.0 phosphate buffer solution, add the wet cells obtained after centrifugation of 200 milliliters of fermented liquid...

Embodiment 3

[0042] Saccharomyces cerevisiae CGMCC No.2266 strain was inoculated into the slant medium, and cultured at 30° C. for 4 to 6 days to obtain the slant surface of the bacteria. Use an inoculation needle to take an inoculation loop from the slant of the bacterium and inoculate it into a 250mL Erlenmeyer flask containing 100mL of liquid medium, and culture it at 30°C and 180r / min for 24h to obtain a seed solution. The seed solution was inoculated in a 250mL Erlenmeyer flask containing 100mL of liquid medium with a 10% inoculation amount, cultivated at 30°C and 180r / min for 24 hours to obtain a fermentation broth, and the fermentation broth was centrifuged to obtain enzyme-containing bacterial cells. The dry weight of enzyme-containing bacterium cells contained in 1 liter of fermented liquid is 50 grams.

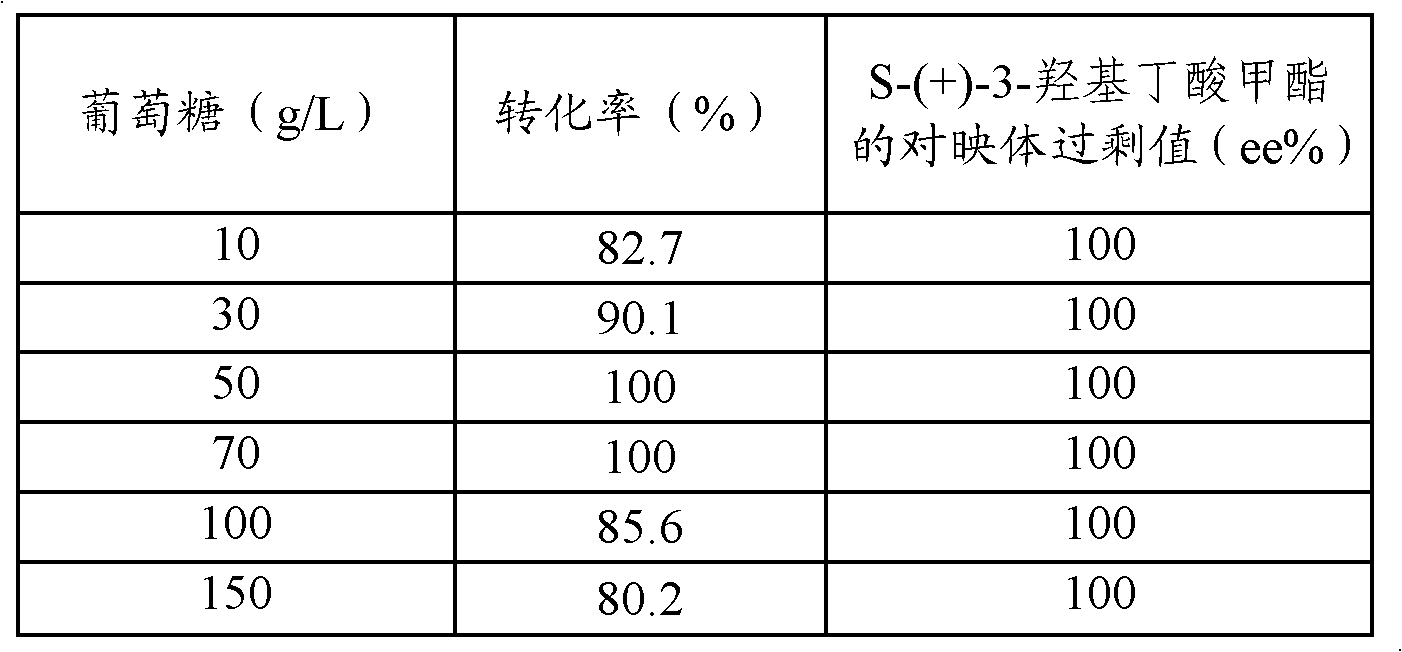

[0043] In five parts of Erlenmeyer flasks containing 100mL pH7.0 phosphate buffer solution, add the wet cells obtained after centrifugation of 200 milliliters of the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com