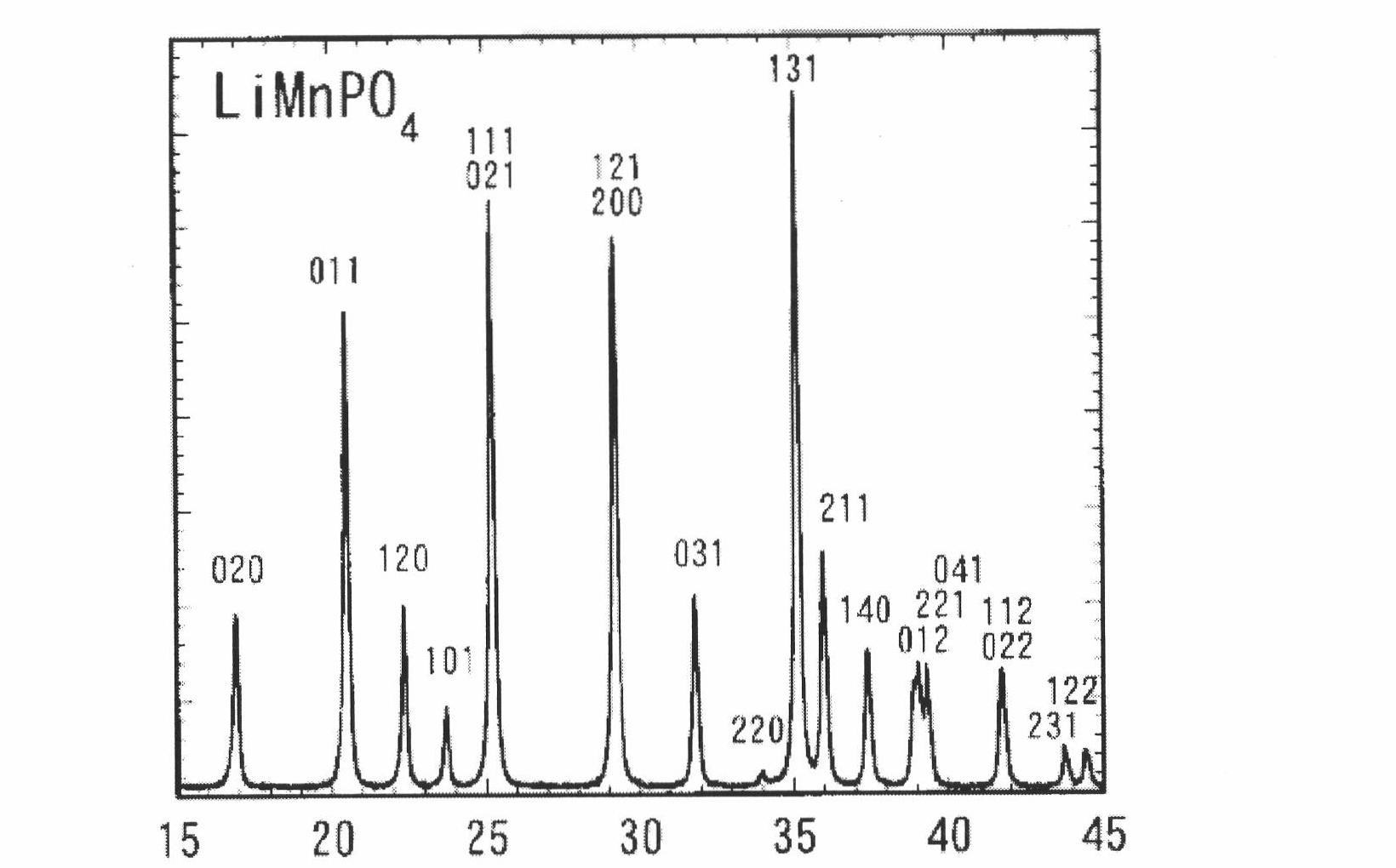

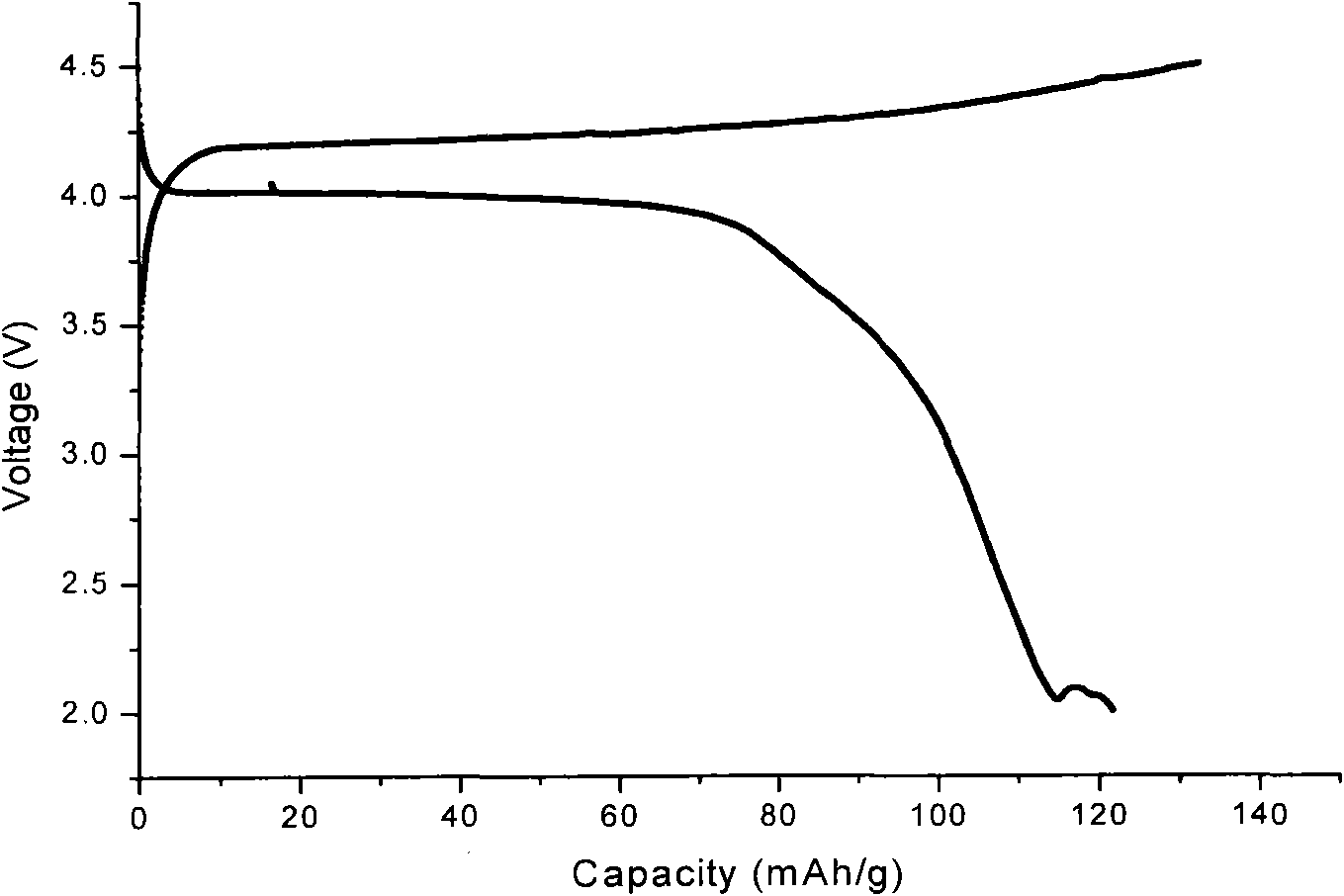

Method for synthesizing manganese lithium phosphate/carbon serving as positive material of lithium ion battery

A lithium-ion battery and synthesis method technology, which is applied in the field of carbon-coated phosphate cathode materials, can solve the problems of low purity of synthetic products and cumbersome operations, and achieve the effects of easy control of experimental conditions, accelerated reaction speed, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of ethanol solution of phenolic resin

[0026] Using resorcinol (AR) and formaldehyde aqueous solution (CR) with a mass percent concentration of 36% as raw materials, dissolve 0.03mol resorcinol and 0.02mol formaldehyde in deionized water, add a small amount of LiOH as a catalyst, and heat at 80°C Heat in a water bath until it becomes gel, dissolve it with 20ml of absolute ethanol while it is still hot, cool to room temperature for later use, and finally obtain an ethanol solution of phenolic resin. After calculation, the carbon element in the phenolic resin has a concentration of 10mol / L in the ethanol solution of the phenolic resin.

[0027] The preparation method of the one-step solid-phase method synthesis lithium manganese phosphate material of the present embodiment, its steps are as follows:

[0028] 1) Mixing process

[0029] Raw material: 0.8g Li 2 CO 3 , 2.32g NH 4 h 2 PO 4 and 2.3gMnCO 3 (the mol ratio of lithium, manganese, phosphorus is ...

Embodiment 2

[0040] Preparation of ethanol solution of phenolic resin

[0041] Using resorcinol (AR) and formaldehyde aqueous solution (CR) with a mass percent concentration of 36% as raw materials, dissolve 0.03mol resorcinol and 0.02mol formaldehyde in deionized water, add a small amount of LiOH as a catalyst, and heat at 80°C Heat in a water bath until it becomes gel, dissolve it with 20ml of absolute ethanol while it is still hot, cool to room temperature for later use, and finally obtain an ethanol solution of phenolic resin. After calculation, the concentration of C atoms in the phenolic resin in the ethanol solution of the phenolic resin is 10mol / L.

[0042] The preparation method of the one-step solid-phase method synthesis lithium manganese phosphate material of the present embodiment, its steps are as follows:

[0043] The first step, the mixing process

[0044] Raw material: 0.89g LiOH·H 2 O, 2.32g NH 4 h 2 PO 4 and 2.3gMnCO 3 (the molar ratio of lithium, manganese, and p...

Embodiment 3

[0051] The preparation method of the one-step solid-phase method synthesis lithium manganese phosphate material of the present embodiment, its steps are as follows:

[0052] The first step, the mixing process

[0053] Take 0.80g Li 2 CO 3 , 2.32g NH 4 h 2 PO 4 and 2.3gMnCO 3 (the molar ratio of lithium, manganese, and phosphorus is 1.05:1:1) into the ball mill jar, then add 0.471g of glucose (calculated, the quality of the carbon element in the glucose is 3.5% of the raw material quality), and finally add acetone to dissolve the raw material and glucose Submerged and ball milled at 250rpm for 12h.

[0054] In the second step, the mixture is dried

[0055] After the ball milling is completed, the obtained mixture is taken out and placed in an evaporating dish, dried at 100° C., and ground into a powder.

[0056] The third step, calcining

[0057] Transfer the powder of the above mixture to a porcelain boat, in the Ar-H 2 (where H 2 The volume fraction is 10%), using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com