Nano wind tube and preparation method thereof

A nano-air duct technology, applied in mining equipment, earth square drilling, mine/tunnel ventilation, etc., can solve the problems of poor flame retardancy and high resistivity of safety air ducts, and achieve good comprehensive mechanical properties and flame retardant Good performance and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

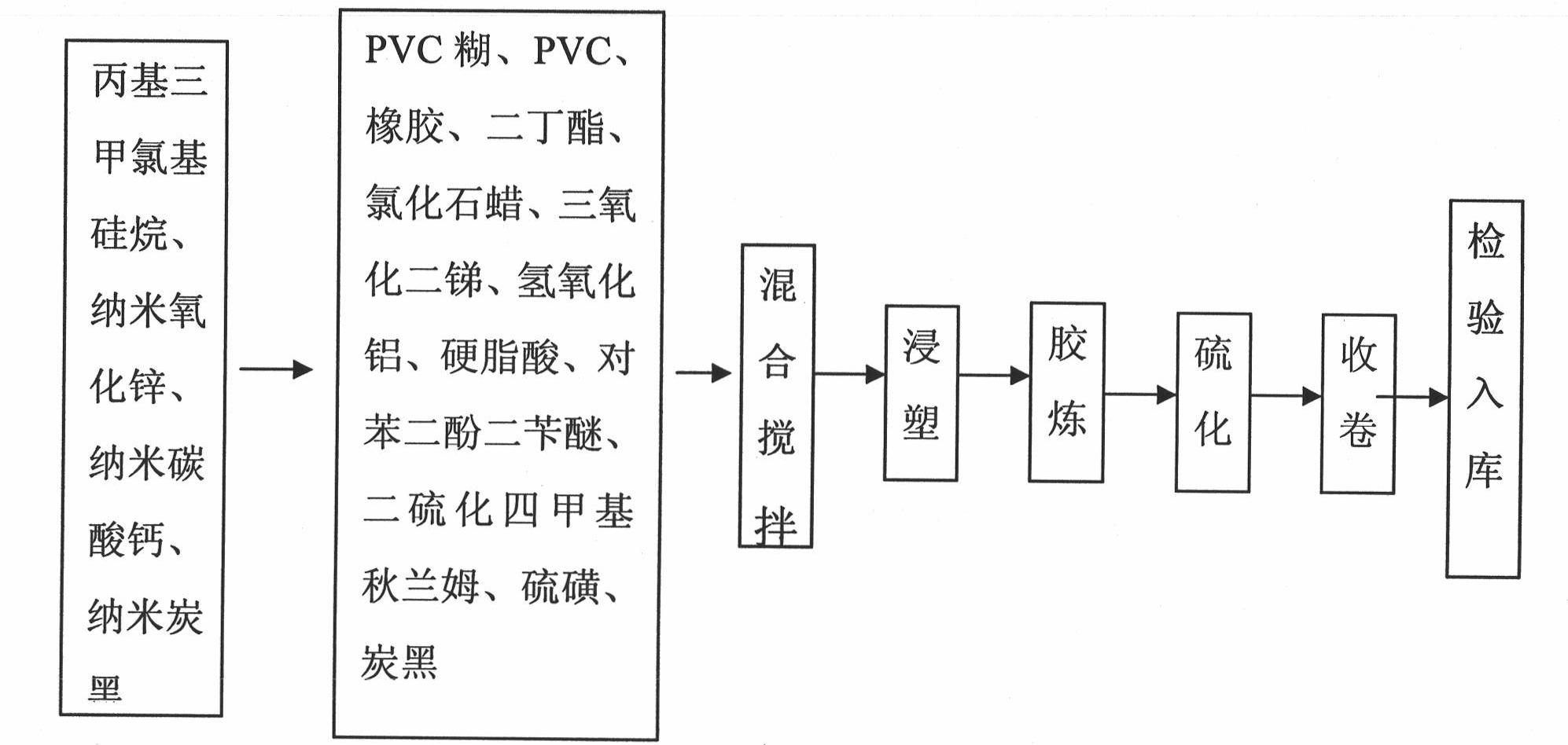

[0024] A kind of preparation method of nano air duct is characterized in that it is carried out according to the following steps:

[0025] (1) After weighing the raw materials according to the dosage, mix 0.2 parts of nano-carbon black, 0.3 parts of nano-ZnO, and 0.2 parts of nano-CaCO 3 Mix and stir with 0.2 parts of propyltrimethylchlorosilane at normal temperature;

[0026] (2) Mix 2 parts of PVC paste, 10 parts of PVC, 20 parts of rubber, 5 parts of dibutyl ester, 2 parts of chlorinated paraffin, 2 parts of antimony trioxide, 2 parts of aluminum hydroxide, 0.2 parts of stearic acid, 0.2 parts Hydroquinone dibenzyl ether, 0.2 parts of tetramethylthiuram disulfide, 0.2 parts of sulfur, 2 parts of carbon black and the material obtained in step (1) are mixed, and the mixture is heated at 40°C to 60°C by a rubber mill Mix for 10-20 minutes to form a film;

[0027] (3) Cover two pieces of rubberized polymer composite material on the glass fiber net, vulcanize and mold at 140-1...

Embodiment 2

[0035] Add 2 parts of potter's clay in the rubber mixing process of the step (2) of embodiment 1, other are with embodiment 1. After clay is added in the rubber mixing process, the production cost of the material can be reduced.

Embodiment 3

[0037] A kind of preparation method of nano air duct is carried out according to the following steps:

[0038] (1) After weighing the raw materials according to the dosage, mix 0.2 parts of nano-carbon black, 0.3 parts of nano-ZnO, and 0.2 parts of nano-CaCO 3 Mix and stir with 0.3 parts of propyltrimethylchlorosilane at normal temperature;

[0039] (2) Mix 3 parts of PVC paste, 11 parts of PVC, 22 parts of rubber, 0.3 parts of zinc oxide, 6 parts of dibutyl ester, 3 parts of chlorinated paraffin, 3 parts of antimony trioxide, 3 parts of aluminum hydroxide, 0.3 parts of hard Fatty acid, 0.3 part of hydroquinone dibenzyl ether, 0.3 part of tetramethylthiuram disulfide, 0.3 part of sulfur, 2 parts of carbon black and the material that step (1) obtains are mixed, through rubber mill at 40 ℃ Rubber mixing at ~60°C for 10-20 minutes to form a film;

[0040] (3) Cover two pieces of high polymer composite material that has been rubberized on the glass fiber net, vulcanize and mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com