Modified asphalt composition and production process thereof

A technology of modified asphalt and composition, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, building structures, etc., and can solve the problems of limited addition, difficult materials to handle, and high price of SBS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

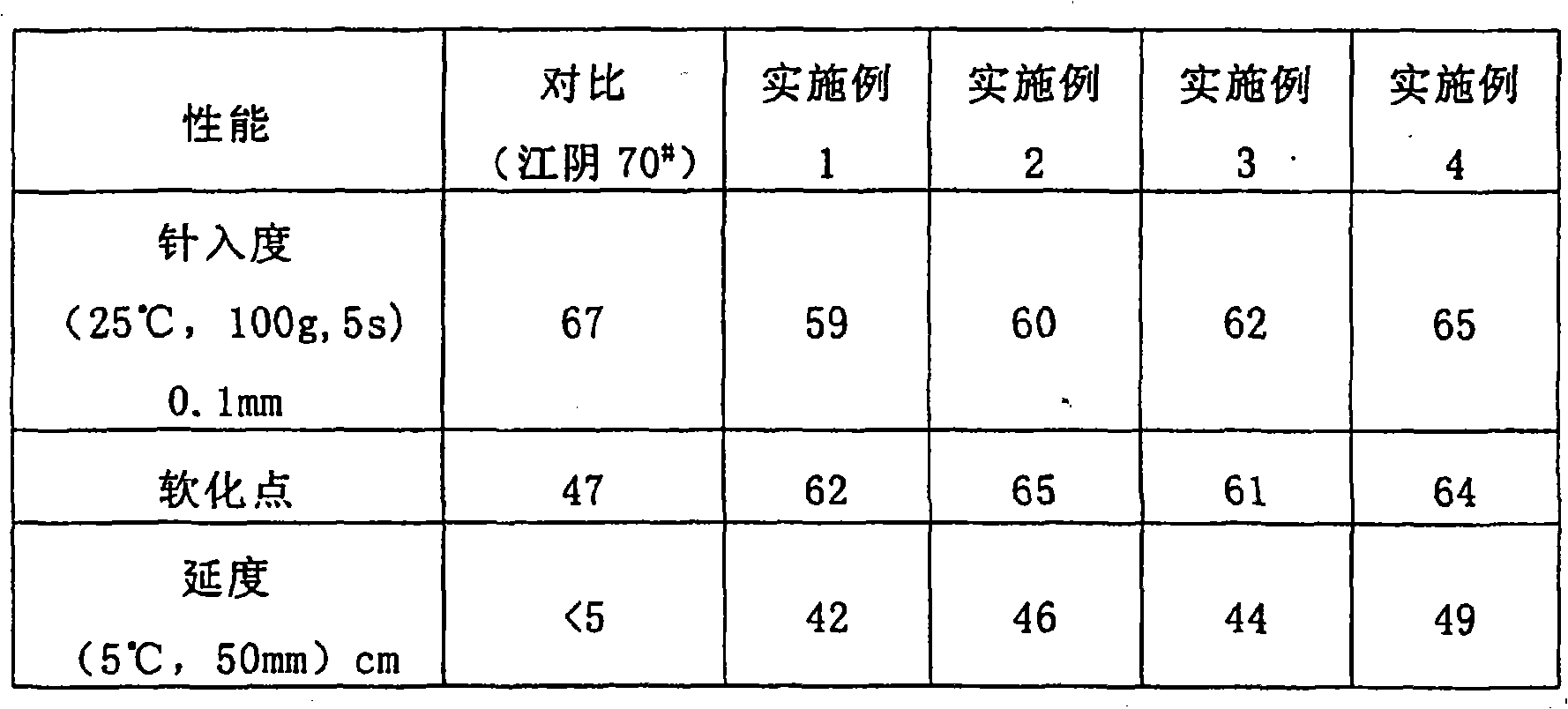

Examples

Embodiment 1

[0046] Step 1: Preparation of modified asphalt masterbatch.

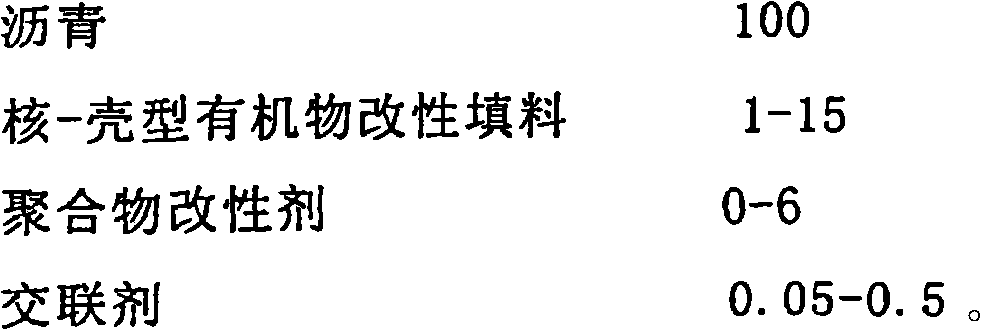

[0047] Proportion of modified asphalt masterbatch (total weight part is 100):

[0048] 50 parts by weight of asphalt

[0049] Core-shell type modified filler 50 parts by weight

[0050] The asphalt is Jiangyin 70# asphalt, the core-shell modifier uses kaolin as inorganic particles, the particle size is 2-20μm, the shell polymer is SBS, and the weight ratio of inorganic filler to polymer is 80:20. Use a high shear emulsifier to disperse and mix, the mixing temperature is 150-180°C, the time is 60min, and the mixing speed is 4500 rpm / hour

[0051] Step 2: Preparation of reactive masterbatch

[0052] The distribution ratio of each group:

[0053] Asphalt 95 (parts by weight)

[0054] Sulfur 5 (parts by weight)

[0055] The asphalt is Jiangyin 70# asphalt, the sulfur is general industrial grade, the mixing temperature is 100°C, a high-shear emulsifier is used, the mixing time is 20 minutes, and the mixing speed is...

Embodiment 2

[0059] Adopt the same method in Example 1 to prepare modified asphalt masterbatch and reactive masterbatch, by weight: 100 parts of asphalt, 20 parts of modified asphalt masterbatch, 5 parts of reactive masterbatch, put in common asphalt stirring device Stir in medium temperature at 190°C and react for 20 minutes to obtain asphalt composition.

Embodiment 3

[0061] Step 1: Preparation of modified asphalt masterbatch

[0062] Modified asphalt masterbatch component distribution ratio (the total weight part is 100):

[0063] Asphalt 50 (parts by weight)

[0064] Core-shell modifier 40 (parts by weight)

[0065] SBS 10 (parts by weight)

[0066] The asphalt and core-shell modifier used are the same as in Example 1, and the SBS is Yuehua product XH-792. Use a high-shear emulsifier for mixing, the mixing temperature is 150-180°C, the mixing time is 60min, and the mixing speed is 4500 rpm.

[0067] Step 2: Preparation of reactive masterbatch

[0068] The preparation of the reactive masterbatch is the same as in Example 1.

[0069] Step 3: Preparation of asphalt composition

[0070] According to the weight ratio: 100 parts of asphalt, 15 parts of modified asphalt masterbatch, 3 parts of reactive masterbatch were placed in a common asphalt mixing device and mixed at a temperature of 195 ° C for 30 minutes to obtain a modified asphalt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com