Method for transferring fur indumentum patterns

A transfer method and quilt technology, applied in the direction of dyeing, application, coating, etc., can solve the problems of difficult promotion, defective products, waste, etc., and achieve the effect of improving printing quality and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve polyethylene oxide in water to make a 10% (w / w) solution, add 8% urea and 2% sodium bisulfate to the weight of the polymer solution, and apply it with a knife coater. Spread on 100 grams of white paper, dry, and roll up for later use. Then, 20% reactive black kn-b, 3% sodium alginate, and 75% water are prepared into ink according to the weight percentage, and the pattern is selected, printed with a rotary screen printing machine, and rolled up. Lay the above printed transfer paper with sheep shearling, and enter the roller heat transfer machine together, adjust the temperature to 120°C, and adjust the pressure to 15Kg / cm 2 , After transfer printing, tear off the backing paper, and then carry out steaming, the steaming temperature is 90°C, and the time is 15 minutes, and finally carry out post-processing procedures such as washing with water to complete the transfer printing.

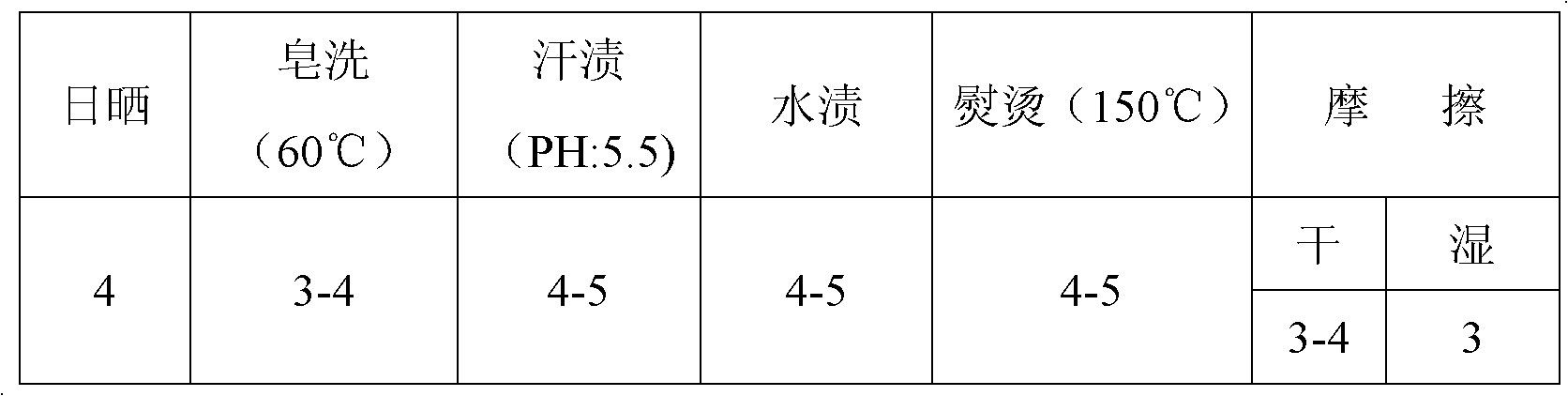

[0034] Through the test, the various fastness indexes of the pattern after printing ...

Embodiment 2

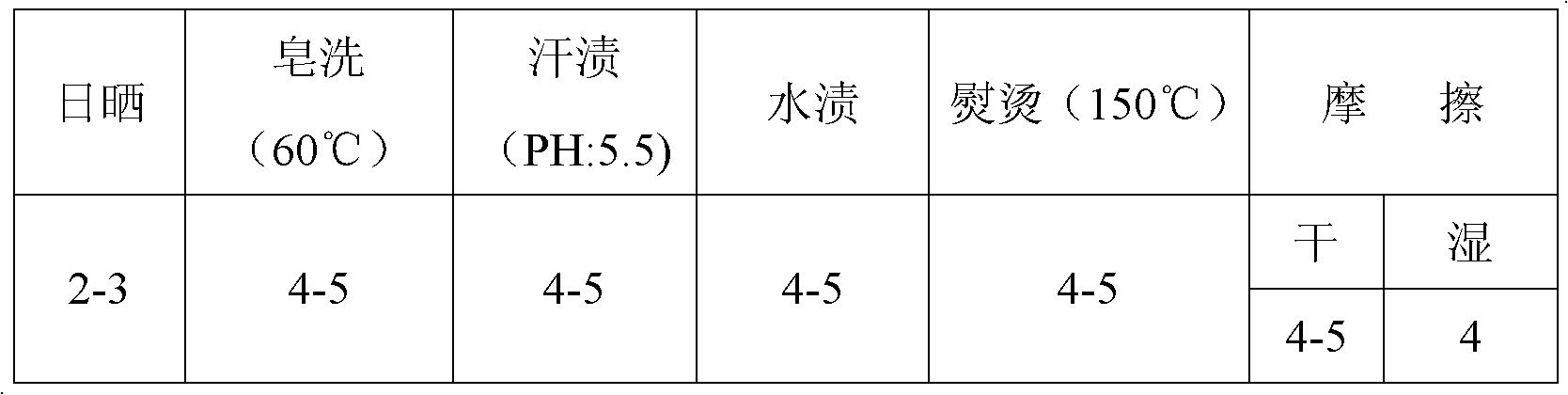

[0038] Polyoxypropylene and polyethylene glycol are mixed at a weight ratio of 5:1, dissolved with 1:1 water and ethanol solution (V / V), and made into a 30% (w / w) solution, and the weight of the polymer solution is added 10% calcium chloride and 2.5% ammonium sulfate by weight of the polymer solution are coated on the BOPP film with a gravure printing machine, dried, and rolled up for later use. 0.5% of weak acid red B, 10% of polyvinyl acetal resin, and 89.5% of methyl alcohol are made into ink by weight percentage, and the pattern is selected. After printing the pattern with a gravure printing machine, it is wound up. Lay the above-mentioned printed transfer film with the rabbit skin, put them into the flat-bed transfer machine together, adjust the temperature to 150°C, and adjust the pressure to 25Kg / cm 2 , after transfer printing, put the rabbit skin together with the transfer film in a steamer for 45 minutes at a temperature of 102°C. Finally, the transfer film is torn o...

Embodiment 3

[0043]Polyoxyethylene and polyethylene glycol are mixed in a weight ratio of 3:2, dissolved in water, and configured as a 20% (w / w) solution, and 11% of the weight of the polymer solution is added. urea, 3% of the weight of the polymer solution is added. % of citric acid, and then evenly coated on the PET film with a coating machine, dried and rolled for subsequent use. Then buy ready-made active yellow inkjet ink, choose the pattern, and use Muto inkjet printer for inkjet printing. Lay the above-mentioned printed transfer film with the horse fur, put it into a flat-bed transfer machine, adjust the temperature to 160°C, and adjust the pressure to 30Kg / cm 2 , After transfer printing, tear off the transfer film, put the fabric and put it in a steamer for 60 minutes at a temperature of 100°C. Finally, post-processing such as water washing is carried out to complete the transfer printing.

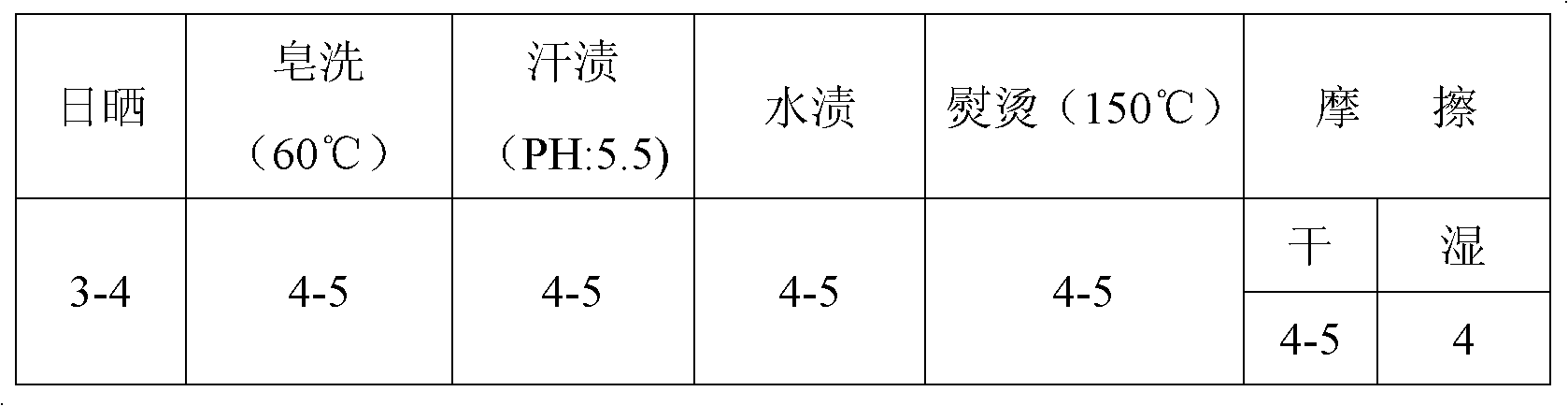

[0044] Through the test, the various fastness indexes of the pattern after printing are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com