Loofah sponge filler used in slightly polluted source water biological pretreatment and pretreatment method

A biological pretreatment and loofah technology, which is applied in the field of water treatment, can solve the problems of insufficient tightness of the film hanging, frequent backwashing, energy waste, etc., so as to achieve no secondary pollution, fast film hanging and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

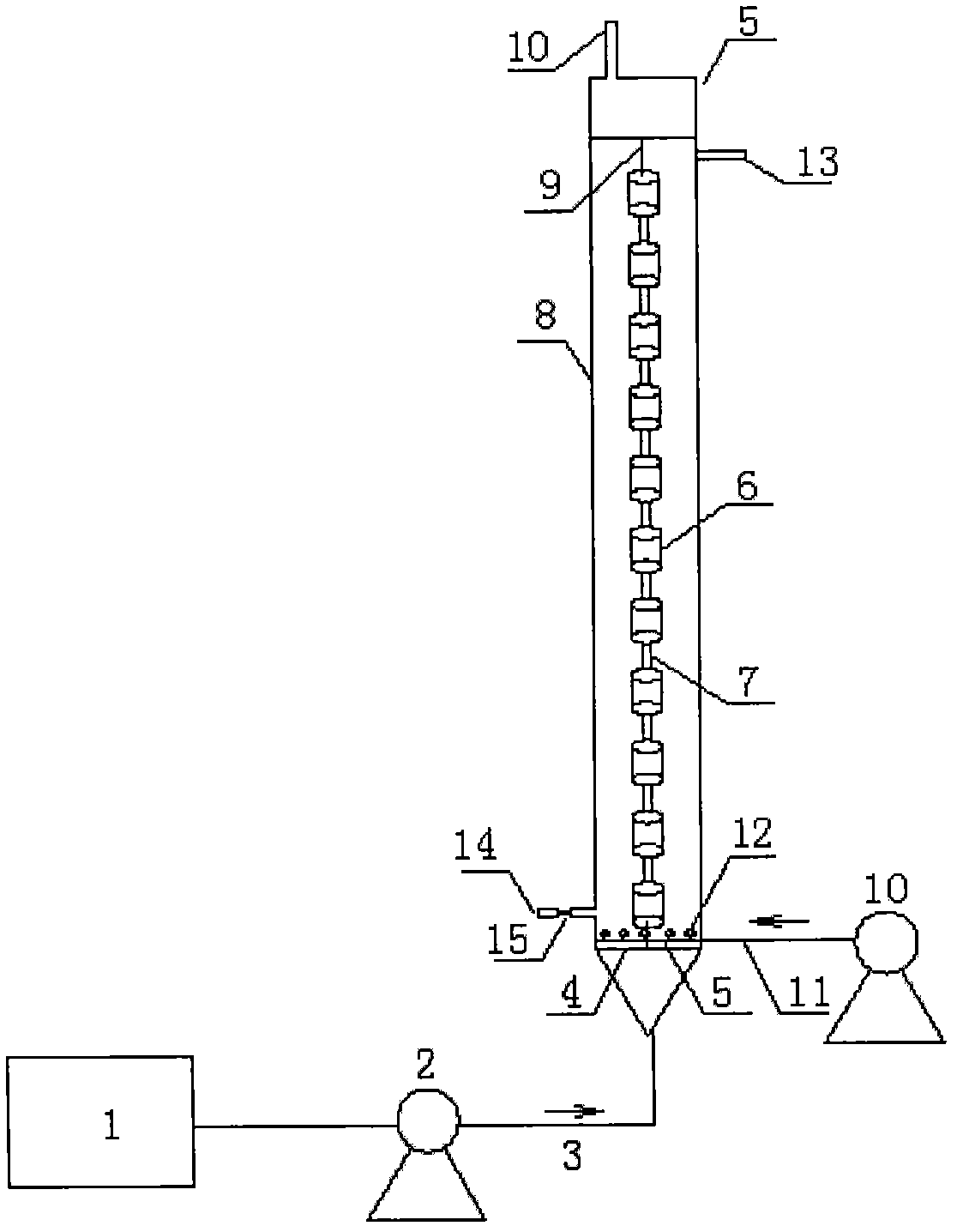

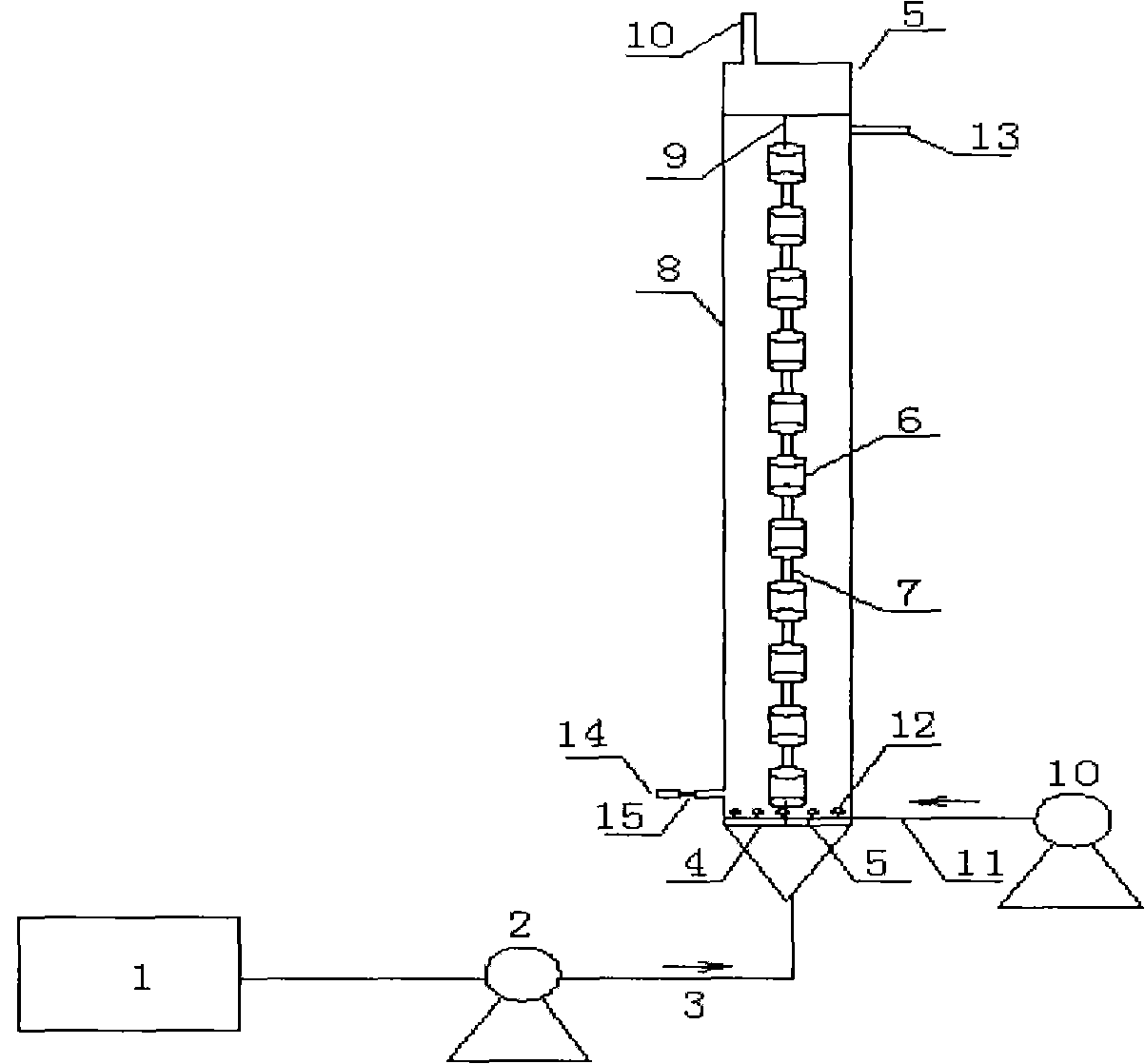

[0023] One, the preparation of loofah filler

[0024] (1) Choose a mature loofah with air-dried skin, remove the skin and seeds to obtain a columnar natural loofah, cut off the thin and irregular parts at both ends, and cut the remaining part into a columnar loofah with a thickness of about 2cm, the diameter of the loofah About 4.0 ~ 4.5cm.

[0025] (2) Use high-strength glass fiber filaments to firmly connect 40 columnar loofahs made in (1) and connect them in series. Each columnar loofah is separated by a small leather tube with a thickness of 1 cm to keep the distance between the fillers. .

[0026] (3) 1 string of the series loofah obtained in (2) is put into a cylindrical bioreactor with an inner diameter of 5.0 cm and a height of 1.50 m, and the upper and lower ends are respectively fixed on the stainless steel wire mesh at both ends of the reactor.

[0027] 2. Luffa filler is used for biological pretreatment of micro-polluted water sources

[0028] (1) Mix the aerobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com