Preparation method of anode material of lithium-ion power battery lithium vanadium phosphate

A technology for power batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of large investment in industrial production equipment, cumbersome gel making process, and poor cycle stability, so as to facilitate industrial production and electrochemical reactions. The effect of many active sites and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

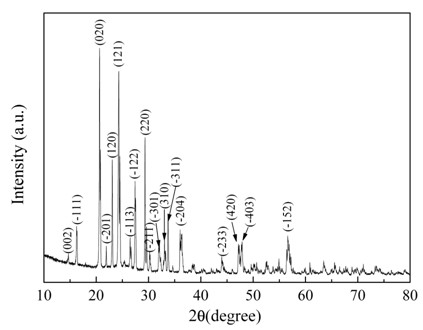

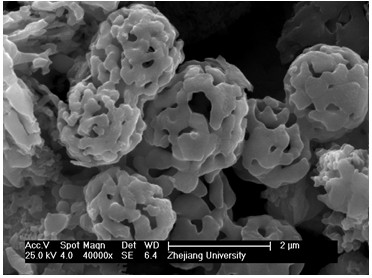

Image

Examples

Embodiment 1

[0024] 1) Prepare white turbid NH with a concentration of 50 g / L with deionized water 4 VO 3 Solution and LiOH·H with a concentration of 100 g / L 2 O aqueous solution, LiOH·H 2 Add O aqueous solution to NH 4 VO 3 Stir evenly in the white turbid solution until the solution becomes clear;

[0025] 2) Add hydrazine hydrate dropwise to the solution prepared in step 1) until the solution turns light yellow;

[0026] 3) Use deionized water to prepare (NH) with a concentration of 100 g / L 4 ) 2 HPO 4 Aqueous solution, and then add this aqueous solution to the light yellow solution in step 2) to obtain a brown-black solution;

[0027] 4) Add NH to the brown-black solution 4 VO 3 1,4-butynediol with a mass of 20%, add ammonia while stirring to adjust the pH of the solution to 10;

[0028] 5) Place the solution obtained in step 4) in a polytetrafluoroethylene reactor, fully react at 180 °C, rinse with deionized water, and dry to obtain precursor powder; then, under 700 °C, argon protection, The p...

Embodiment 2

[0033] 1) Prepare white turbid NH with a concentration of 70 g / L with deionized water 4 VO 3 Solution and LiOH·H with a concentration of 120 g / L 2 O aqueous solution, LiOH·H 2 Add O aqueous solution to NH 4 VO 3 Stir evenly in the white turbid solution until the solution becomes clear;

[0034] 2) Add hydrazine hydrate dropwise to the solution prepared in step 1) until the solution turns light yellow;

[0035] 3) Prepare (NH) with a concentration of 110 g / L with deionized water 4 ) 2 HPO 4 Aqueous solution, and then add this aqueous solution to the light yellow solution in step 2) to obtain a brown-black solution;

[0036] 4) Add NH to the brown-black solution 4 VO 3 1,4-butynediol with a mass of 40%, add ammonia while stirring to adjust the pH of the solution to 12.5;

[0037] 5) Place the solution obtained in step 4) in a polytetrafluoroethylene reactor, fully react at 200 °C, rinse with deionized water, and dry to obtain precursor powder; then, under 750 °C, argon protection, The p...

Embodiment 3

[0042] 1) Prepare white turbid NH with a concentration of 100 g / L with deionized water 4 VO 3 Solution and LiOH·H with a concentration of 140 g / L 2 O aqueous solution, LiOH·H 2 Add O aqueous solution to NH 4 VO 3 Stir evenly in the white turbid solution until the solution becomes clear;

[0043] 2) Add hydrazine hydrate dropwise to the solution prepared in step 1) until the solution turns light yellow;

[0044] 3) Prepare (NH) with a concentration of 120 g / L with deionized water 4 ) 2 HPO 4 Aqueous solution, and then add this aqueous solution to the light yellow solution in step 2) to obtain a brown-black solution;

[0045] 4) Add NH to the brown-black solution 4 VO 3 1,4-Butynediol with a mass of 60%, add ammonia while stirring to adjust the pH of the solution to 14;

[0046] 5) Put the solution obtained in step 4) in a polytetrafluoroethylene reactor, fully react at 220 °C, rinse with deionized water, and dry to obtain precursor powder; then, under the protection of 800 °C and argon,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com