Faraday magnetic rotation transparent ceramic and preparation method thereof

A magneto-optical and ceramic technology, which is applied in the field of Faraday magnetically-optical transparent ceramic materials, can solve the problems of large device volume, poor transmittance, crystal components deviating from the melting point of the melt, etc., and achieve simple preparation process and high optical transmittance , the effect of easy batch preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

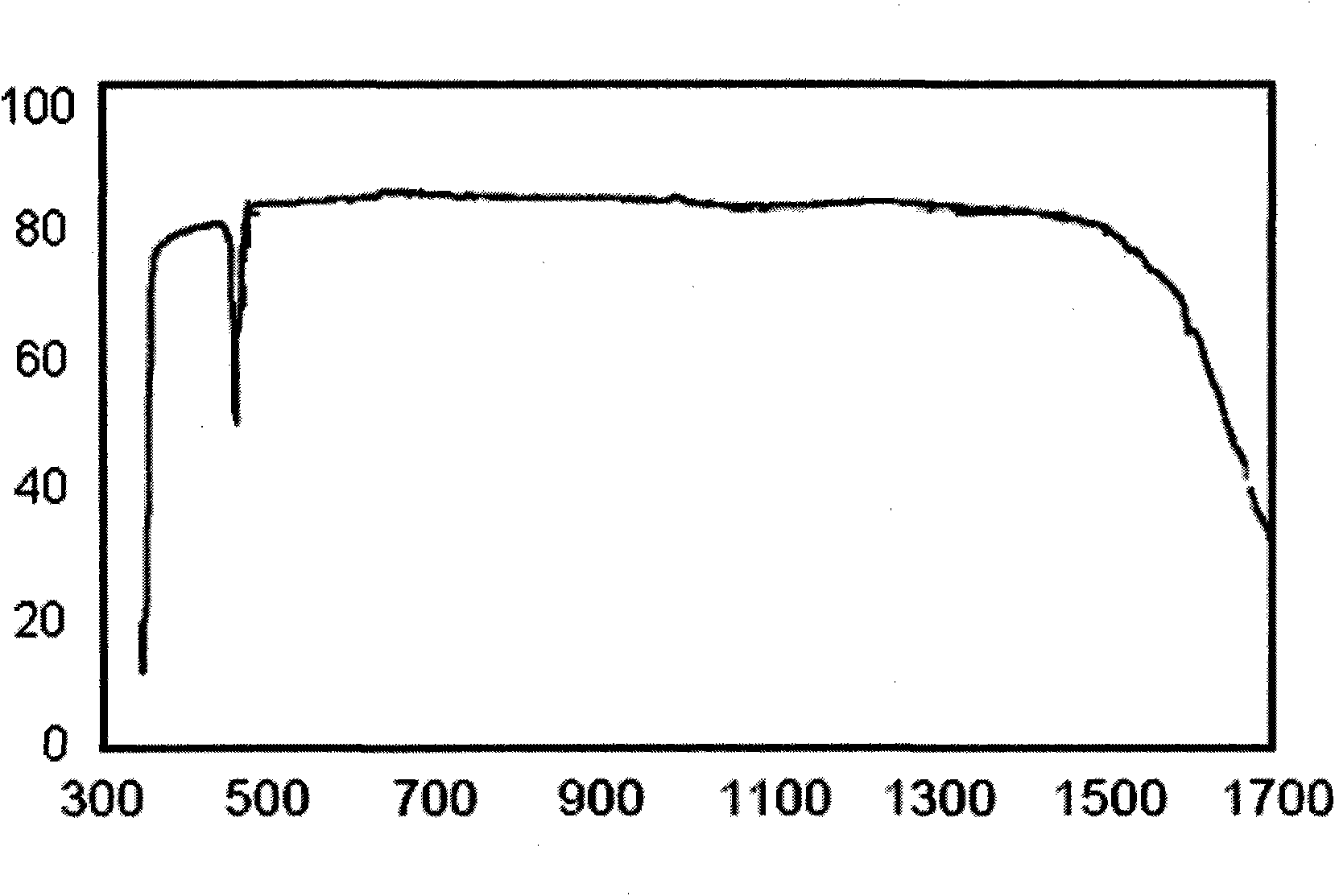

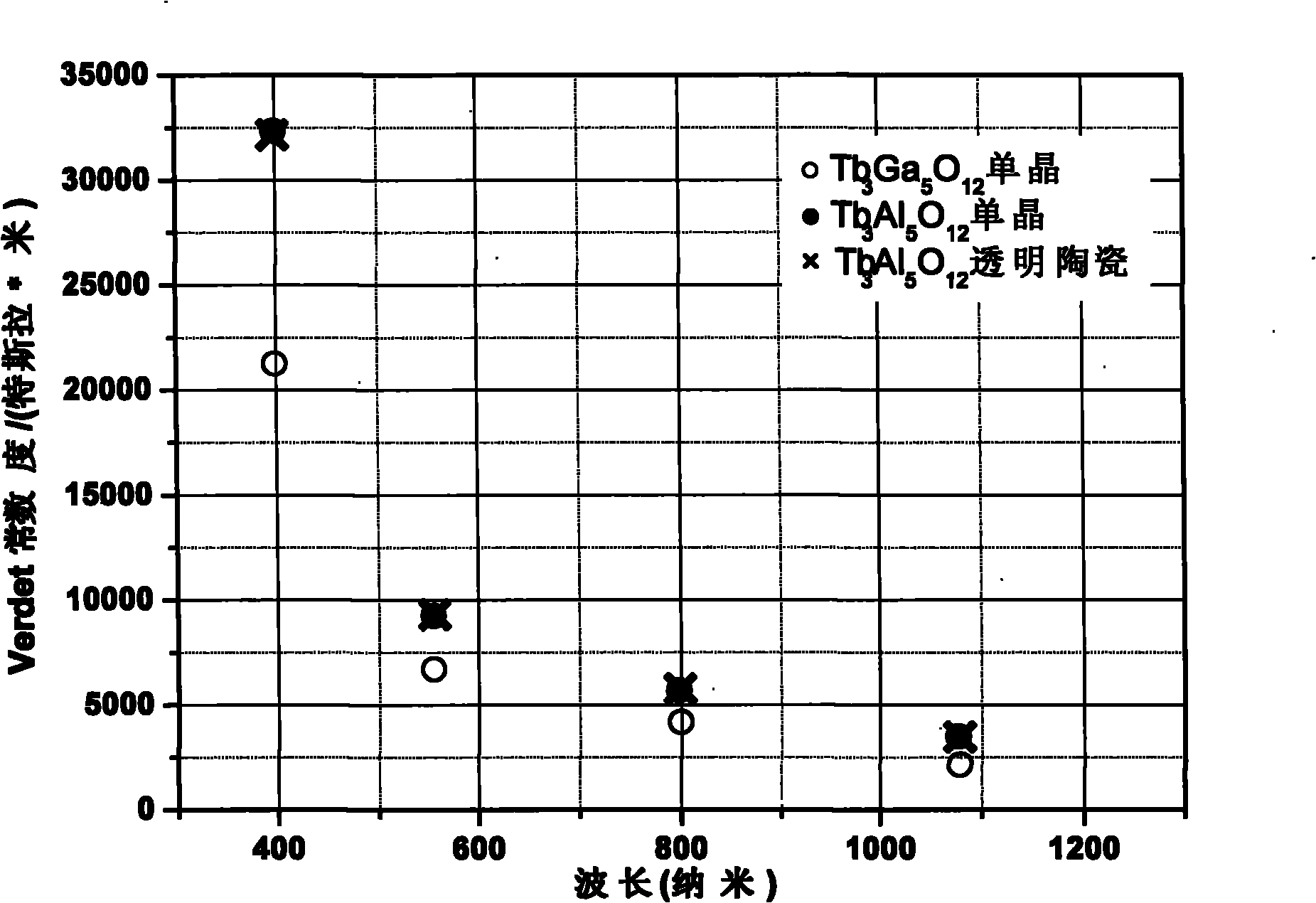

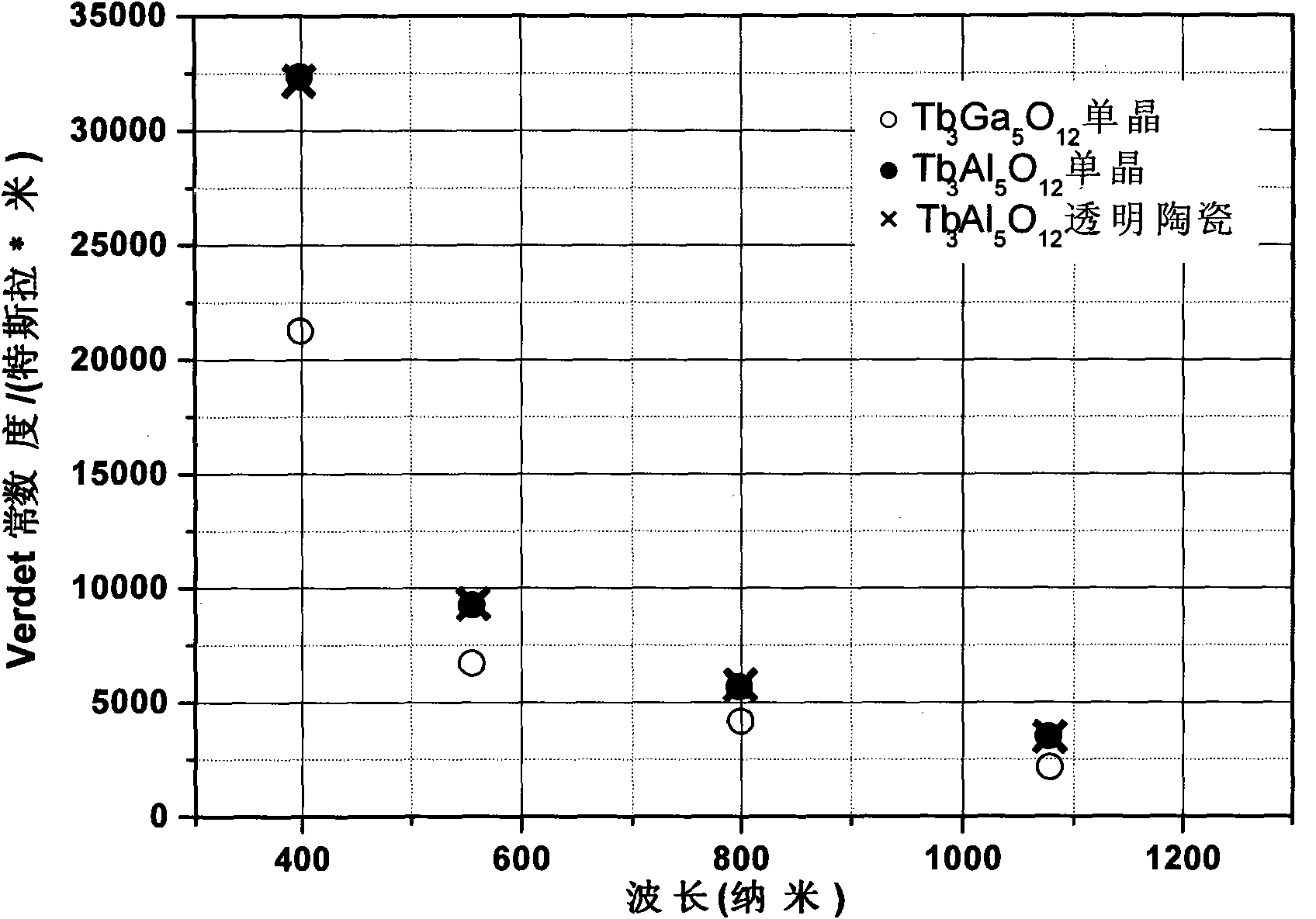

[0036] Example 1Tb 3 Al 5 o 12 Preparation of Transparent Faraday Magnetic Optical Ceramics

[0037] Tb 3 Al 5 o 12 The preparation method of transparent Faraday magnetic optical ceramics, the specific steps are as follows:

[0038] ① The initial raw materials are powders of tetraterbium heptoxide, terbium trioxide, terbium aluminate, alumina, yttrium oxide, thulium oxide, lutetium oxide, gadolinium oxide, scandium oxide, and gallium oxide with a purity of not less than 99.9%.

[0039] ②Molecular formula Tb of transparent Faraday magneto-optic ceramics prepared as required 3 Al 5 o 12 composition and determine the value of x=0, y=0, the purity of terbium oxide (Tb 4 o 7 ), alumina (Al 2 o 3 ) powder as the raw material, according to the molar ratio of each metal ion in the composition, a total of 30g of powder raw material is prepared accordingly, and 0.3wt% to 0.7wt% ethyl orthosilicate is added as an additive, and the powder is mixed and finely ground by ball mil...

Embodiment 2

[0046] The sintering holding temperature is 1650°C, other conditions are the same as in Example 1, and Tb can also be obtained 3 Al 5 o 12 Transparent ceramic.

Embodiment 3

[0048] The sintering holding temperature is 1500°C, and the other conditions are the same as in Example 1, and Tb can also be obtained 3 Al 5 o 12 Transparent ceramic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com