High-efficiency foaming agent for explosives

A foaming agent and high-efficiency technology, which is applied in the field of special sensitizers for emulsion explosives, can solve the problems of poor storage stability of emulsion explosives, affect the blasting performance of emulsion explosives, and unsatisfactory foaming effects, etc., and achieve long natural storage period and weak acidity , The effect of fast foaming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] 1) Mix 1 g of thiourea, 4 g of potassium nitrite, 1.2 g of urea, 25 g of sodium nitrite, and 68.8 g of water to make 100 g of agent A; take 0.8 g of nitric acid and 9 g of ammonium nitrate g, ammonium chloride is 0.3 g, phosphoric acid is 0.4 g, diammonium hydrogen phosphate is 1.5 g, ammonium thiocyanate is 1.5 g, citric acid is 2.1 g, glacial acetic acid is 1 g, urea nitrate is 2 g, urea is 1.2 g and 80.2 g of water are mixed to make 100 g of agent B;

[0009] 2) Mix the above-mentioned agent A and agent B at a weight ratio of 1:1.3 to obtain the blowing agent of the present invention.

[0010] The amount and quality index of blowing agent:

[0011] Dosage: Generally, the amount of agent A added is 0.3-0.5% (percentage by weight) of the emulsion explosive, and the amount of agent B added is 1.2-1.5 times that of agent A of the emulsion explosive.

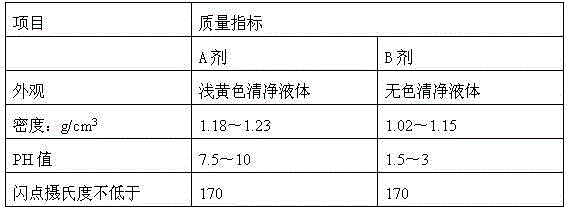

[0012] Quality index of blowing agent (see Table 1):

[0013] Table 1:

[0014]

Embodiment 2

[0016] 1) Mix 0.5 g of thiourea, 3 g of potassium nitrite, 0.9 g of urea, 20 g of sodium nitrite, and 75.6 g of water to make 100 g of agent A; take 0.7 g of nitric acid and 7 g of ammonium nitrate g, ammonium chloride is 0.2 g, phosphoric acid is 0.2 g, diammonium hydrogen phosphate is 0.5 g, ammonium thiocyanate is 0.1 g, citric acid is 1.8 g, glacial acetic acid is 0.7 g, urea nitrate is 1.5 g, urea is 0.9 g and 86.4 g of water are mixed to form 100 g of agent B;

[0017] 2) Mix the above-mentioned agent A and agent B at a weight ratio of 1:1.2 to obtain the blowing agent of the present invention.

[0018] The consumption and quality index of whipping agent are with embodiment 1.

Embodiment 3

[0020] 1) Mix 1.5g of thiourea, 5g of potassium nitrite, 1.5g of urea, 30g of sodium nitrite, and 62g of water to make 100g of agent A; take 1g of nitric acid and 11g of ammonium nitrate g, ammonium chloride is 0.5 g, phosphoric acid is 0.6 g, diammonium hydrogen phosphate is 2 g, ammonium thiocyanate is 2.5 g, citric acid is 2.5 g, glacial acetic acid is 1.5 g, urea nitrate is 2.5 g, urea is 1.5 g and 74.4 g of water are mixed to make 100 g of agent B;

[0021] 2) Mix the above agent A and agent B at a weight ratio of 1:1.5 to obtain the foaming agent of the present invention.

[0022] The consumption and quality index of whipping agent are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com