Coating capable of absorbing medium and high temperature solar energy selectively and preparation method thereof

A technology for absorbing coating and solar energy, applied in the direction of solar thermal power generation, radiation absorbing coatings, coatings, etc., can solve the problems of low process deposition efficiency, long production cycle, complicated process, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

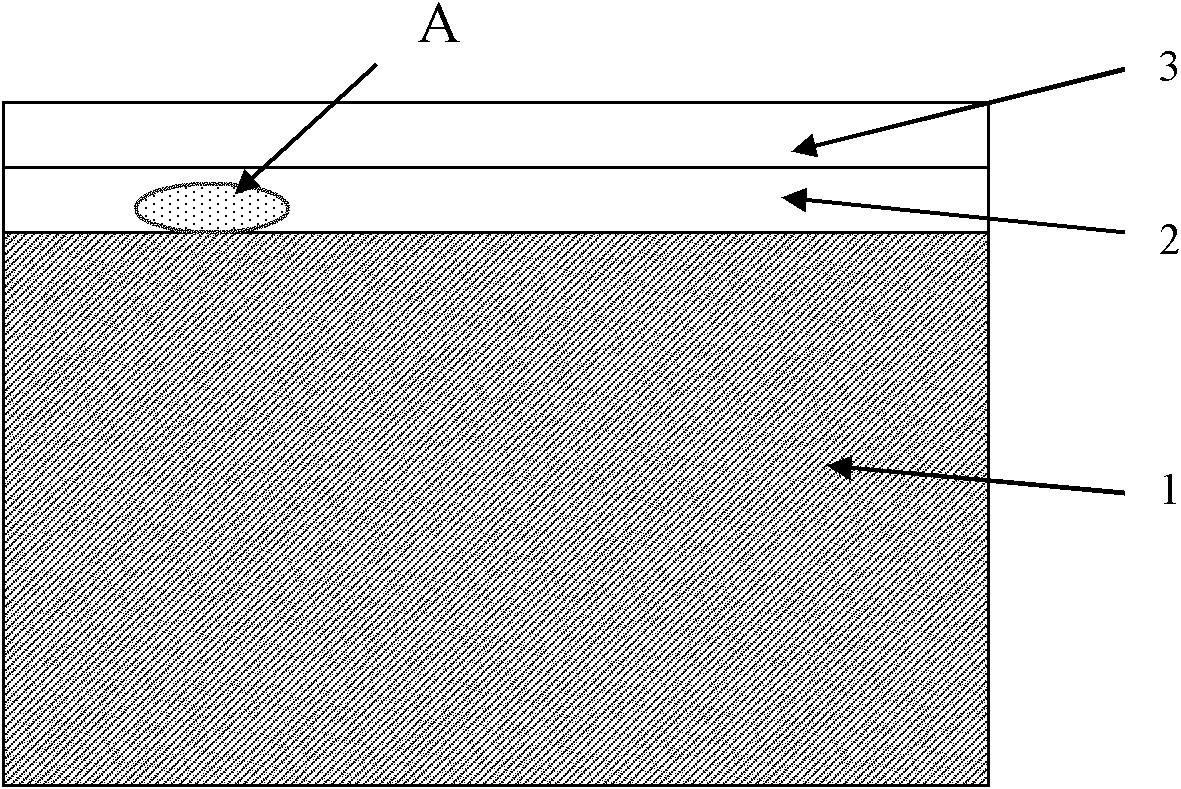

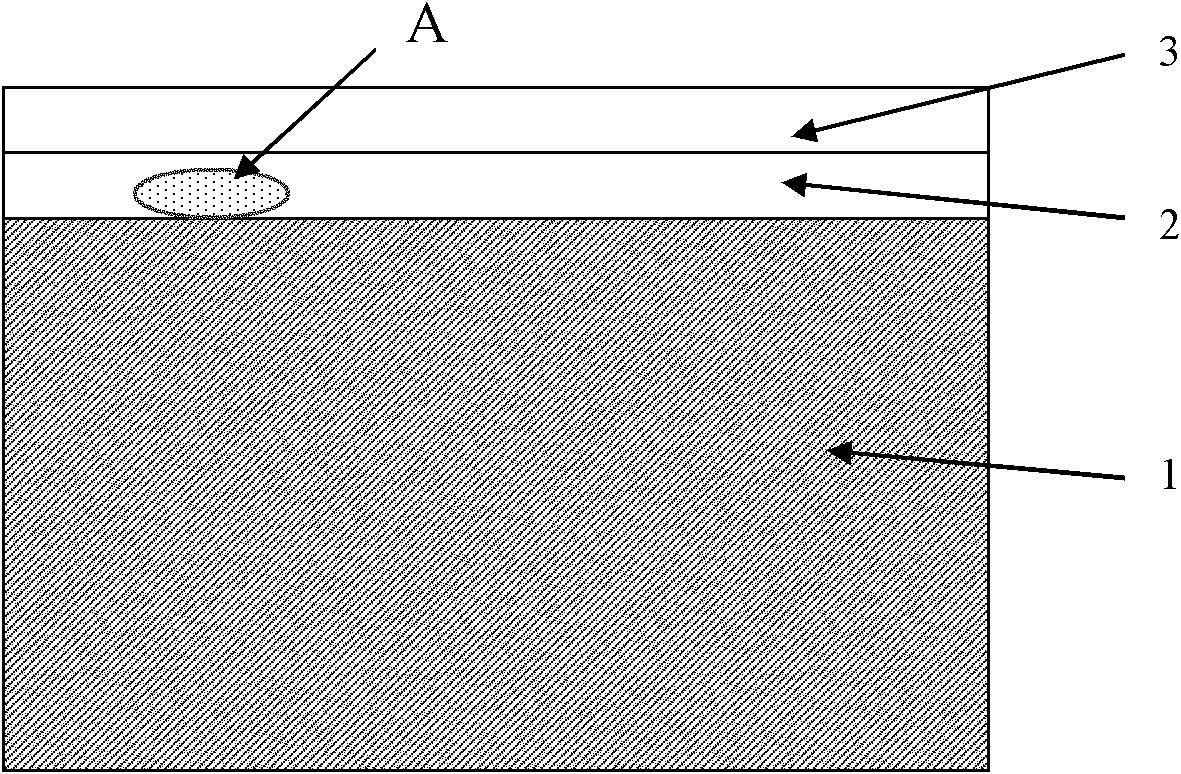

[0035] Example 1: Medium and high temperature solar selective absorption coating

[0036] The coating has a structure of double-layer metal-ceramic layers, such as figure 1 and figure 2 Shown: including the first layer of cermet layer 2 and the second layer of cermet layer 3; using the liquid feeding plasma spraying process, the first group of slurry is sprayed on the surface of the substrate 1 to form the first layer of cermet layer 2 , and then spray the second group of slurry on the surface of the first cermet layer 2 to form the second cermet layer 3 .

[0037] The slurry is prepared by doping metal components into an oxide or nitride ceramic medium and adding deionized water.

[0038] The metal component adopts Mo, W, Ni, Cr or Co fine powder, and its particle size is 40-100 μm.

[0039] The ceramic medium adopts Al 2 o 3 Or AlN powder, the particle size is 40 ~ 100μm.

[0040] The substrate 1 refers to a stainless steel substrate with a grade of 321, or other meta...

Embodiment 2

[0045] Example 2: Preparation of Medium and High Temperature Solar Selective Absorbing Coating

[0046] First prepare the precursor solution doped with metal particles, mix the metal particles into ceramic media such as oxides or nitrides, add deionized water to make a slurry, and then use the liquid feed to spray the slurry on the metal substrate. Prepared as a coating.

[0047] details as follows:

[0048] 1. Configure two sets of precursor slurry:

[0049] (1) Weigh 0.8mol of metal powder Mo, then weigh 0.8mol of ceramic powder Al 2 o 3 Take 10 grams of polyvinyl alcohol, add it to the powder raw material and mix evenly, then add deionized water with a volume of 1L to prepare the first group of slurry.

[0050] (2) Weigh 0.2mol of metal powder Mo, then weigh 0.8mol of ceramic powder Al 2 o 3 Take 10 grams of polyvinyl alcohol, add it to the powder raw material and mix evenly, then add deionized water with a volume of 1L to prepare the second group of slurry.

[0051]...

Embodiment 3

[0057] Example 3: Preparation of Medium and High Temperature Solar Selective Absorbing Coating

[0058] In addition to steps 1 and 2, the metal component of the two groups of precursor slurries configured is W, and the ceramic medium selected is Al 2 o 3 , other preparation methods and performance testing methods are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com