Laminated composite solar battery

A solar cell and composite technology, applied in the field of solar energy, can solve the problems of not making good use of the advantages of the laminated structure, achieve good photoelectric conversion performance, balance production costs, and improve photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

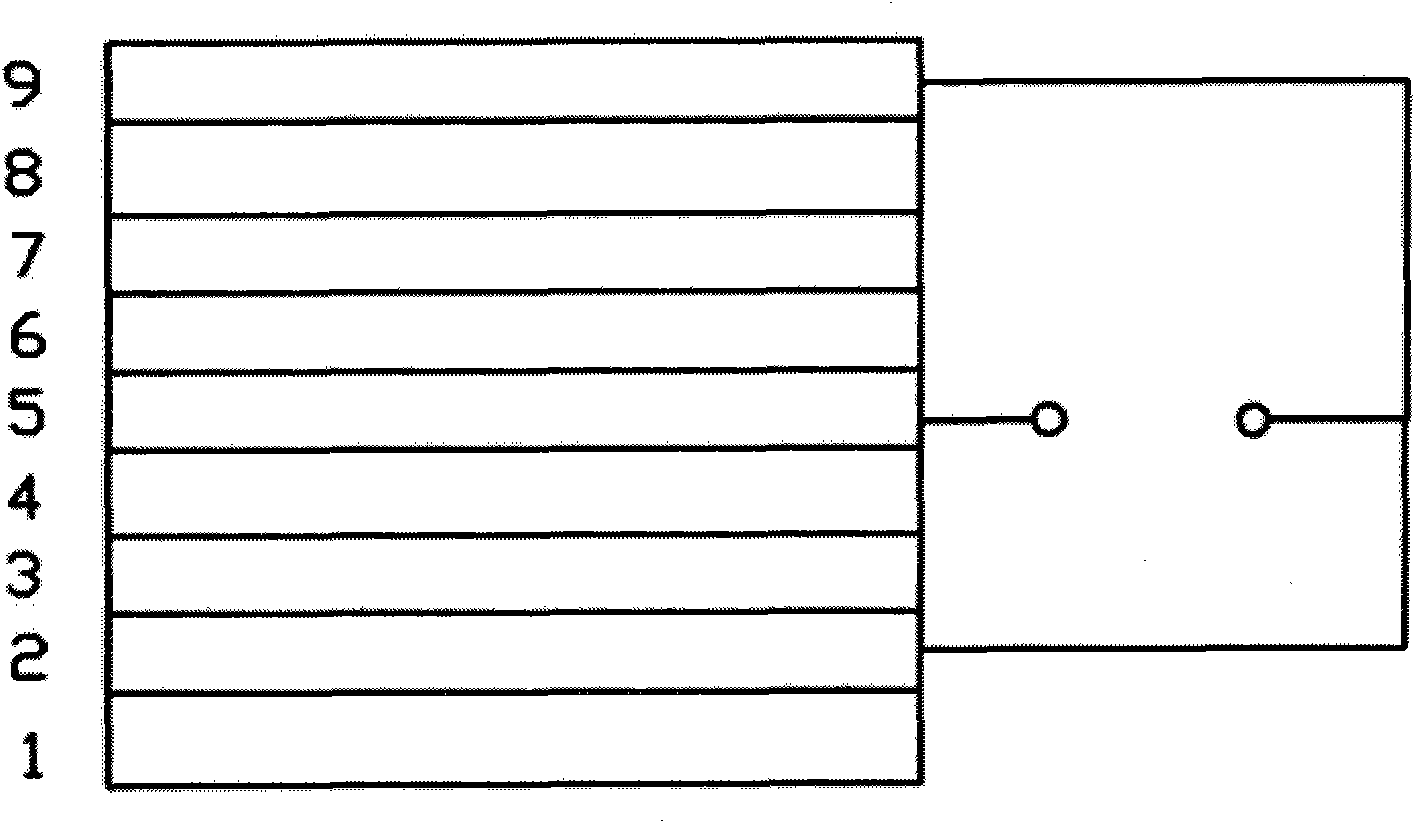

[0028] refer to figure 1 , the inventive solution of this embodiment, the tandem composite solar cell is composed of nine different functional layers. The sequence is a transparent substrate 1, a cathode layer 2, a polar organic layer 3, a first photosensitive layer 4, a semitransparent anode layer 5, a P-type semiconductor layer 6, a P-N transition layer 7, an N-type semiconductor layer 8, and a transparent conductive layer 9; in:

[0029] The transparent substrate 1 is preferably made of glass or plastic; the thickness of the transparent substrate 1 is not particularly limited, and can be appropriately adjusted according to actual needs, but the substrate must have good light transmission performance.

[0030] Cathode layer 2: its material is preferably indium tin oxide or tin oxide; the cathode layer 2 can be formed by any conventional method, such as vapor deposition, sputtering, etc.; the thickness of the cathode layer 2 is between 150-600 nm.

[0031] Polar organic lay...

Embodiment 2

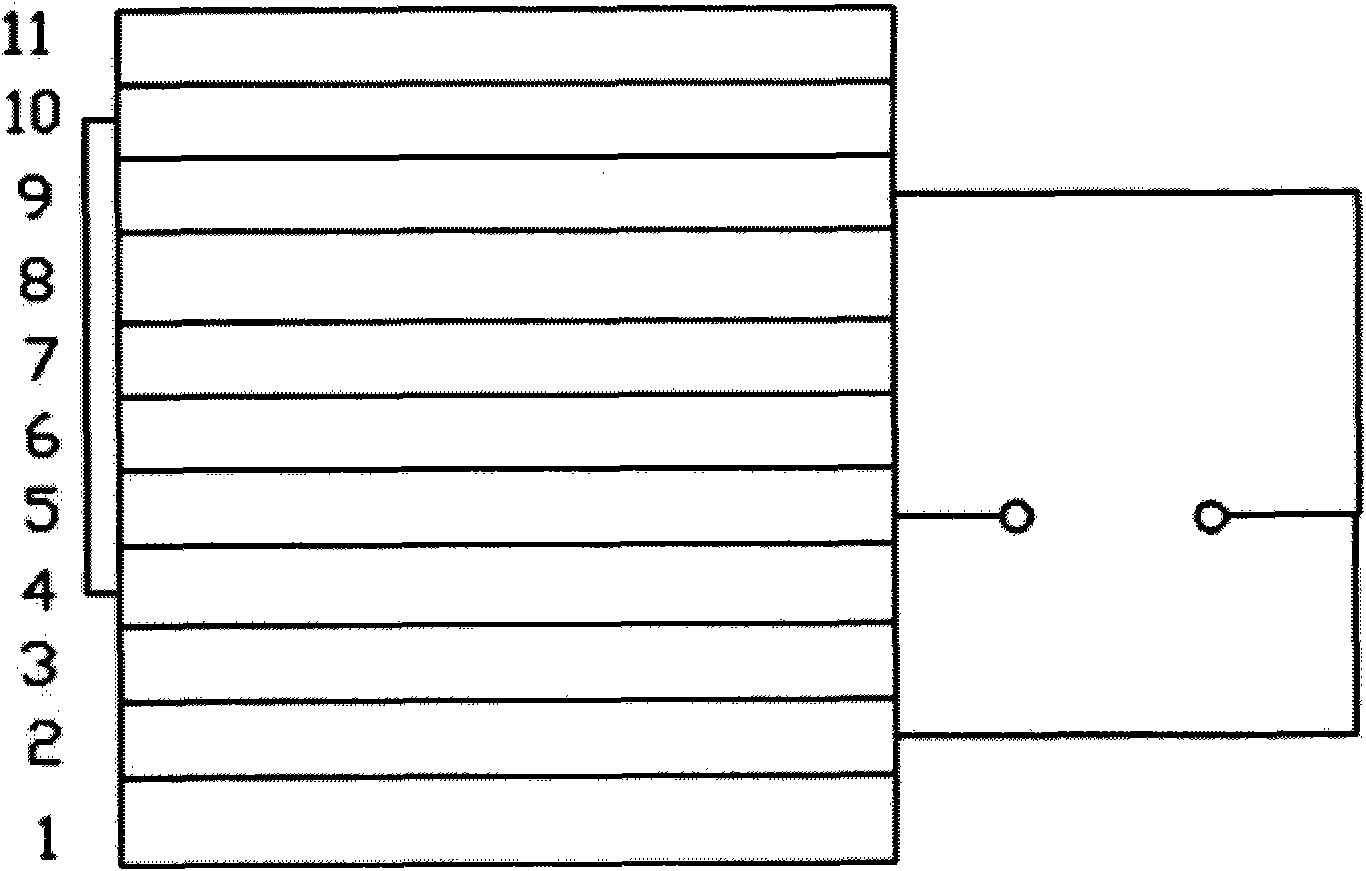

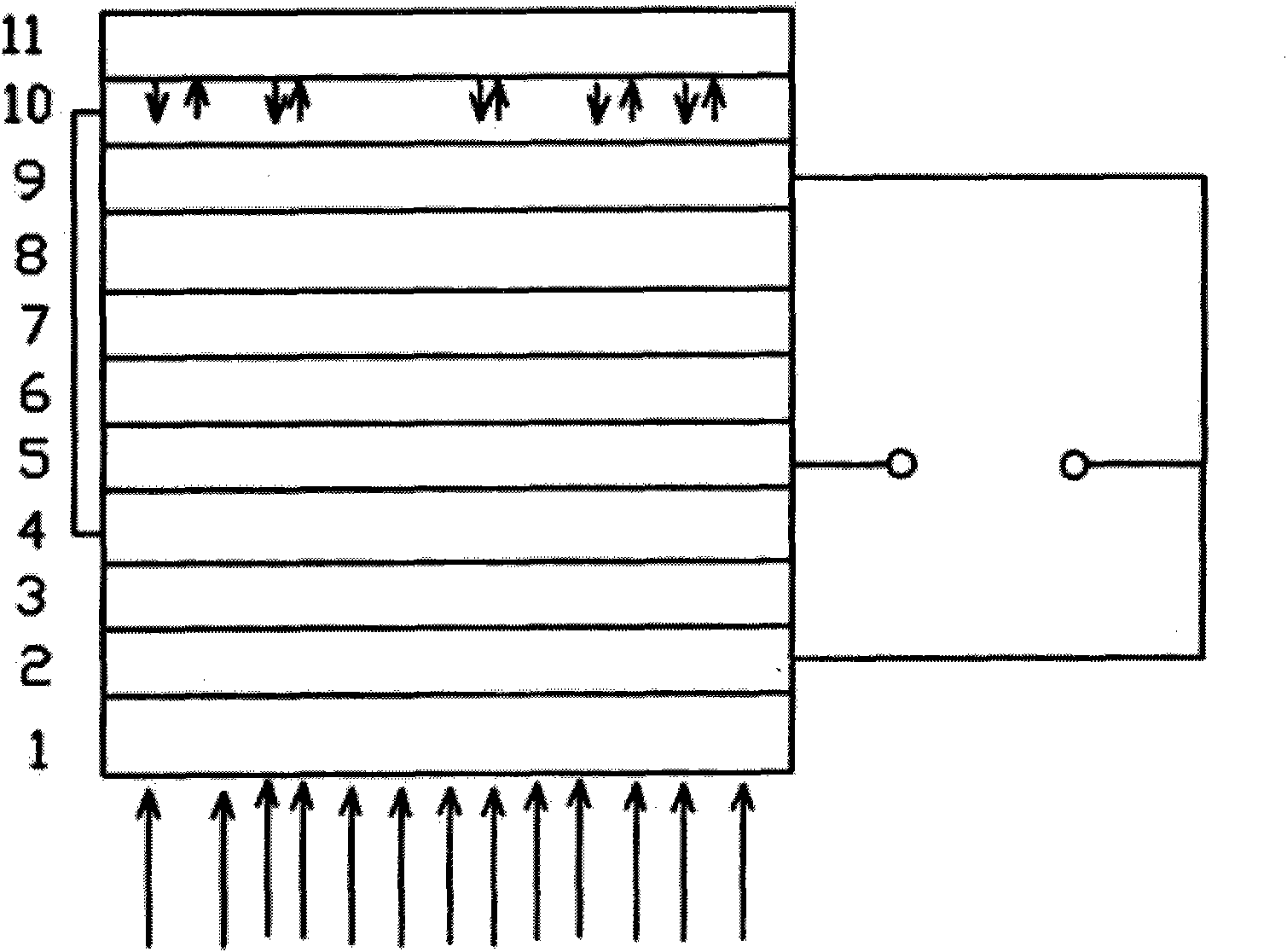

[0040] Embodiment 2 is further optimized on the existing basis of Embodiment 1. The difference is that: reference figure 2 with 3 The semi-transparent anode layer 5 of the laminated composite solar cell also has a second photosensitive layer 10, and the second photosensitive layer 10 and its formation method and thickness can be implemented with reference to the first photosensitive layer 4; the second photosensitive layer 10 also has a non-conductive light-reflective layer. Layer 12, the material can be selected to add high refractive index glass bead reflective paint, which is formed by spraying and other methods. The second photosensitive layer 10 is connected to the first photosensitive layer 4 across layers through a conductor (such as a silver film). refer to image 3 , the afterglow of the sun reaches the non-conductive reflective layer 12 and is reflected, further stimulating the photoelectric induction of the second photosensitive layer 10; the second photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com