ZnO nano-rod photo-anode and preparation method thereof, solar cell

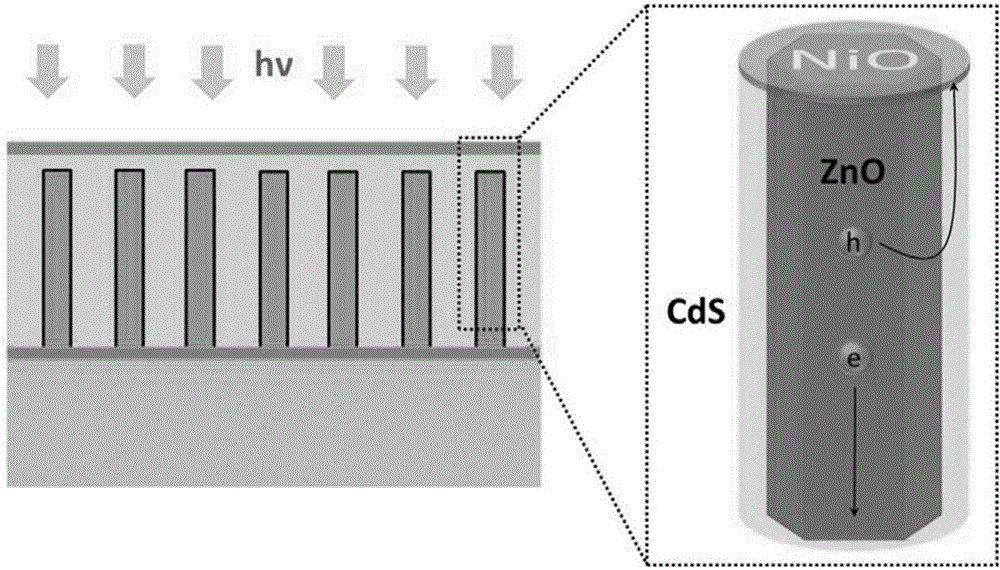

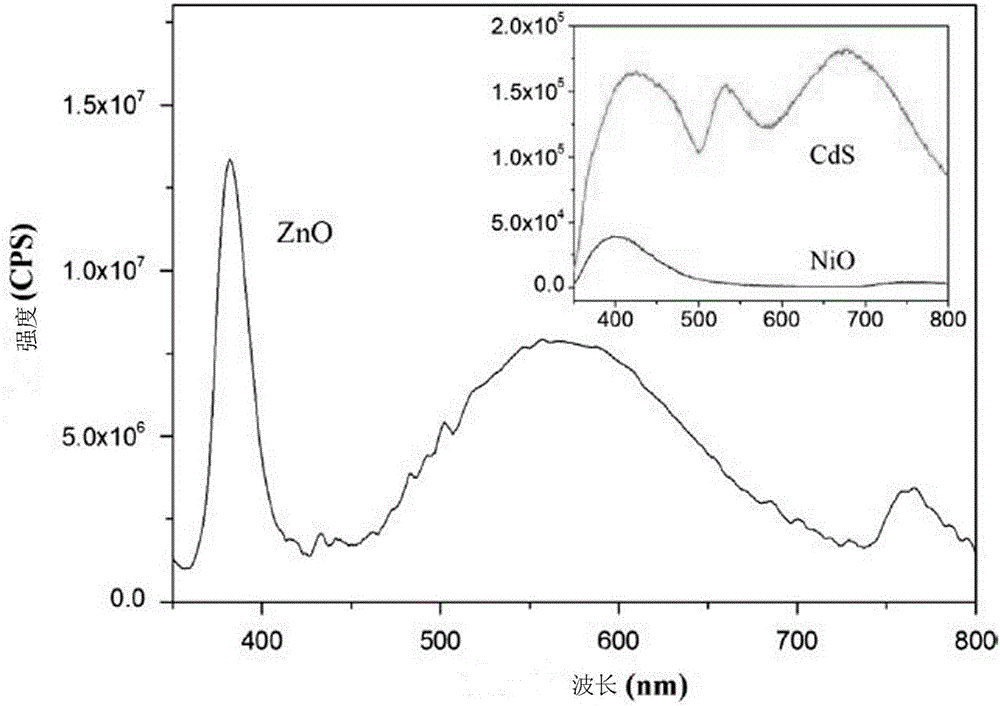

A nanorod and photoanode technology, which is applied in the field of photoelectrodes, can solve the problems of limited use and unsuitability of single-component CdS, and achieve the effects of low cost, improved photoelectrochemical performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Follow the steps below to prepare ZnO nanorod photoanodes:

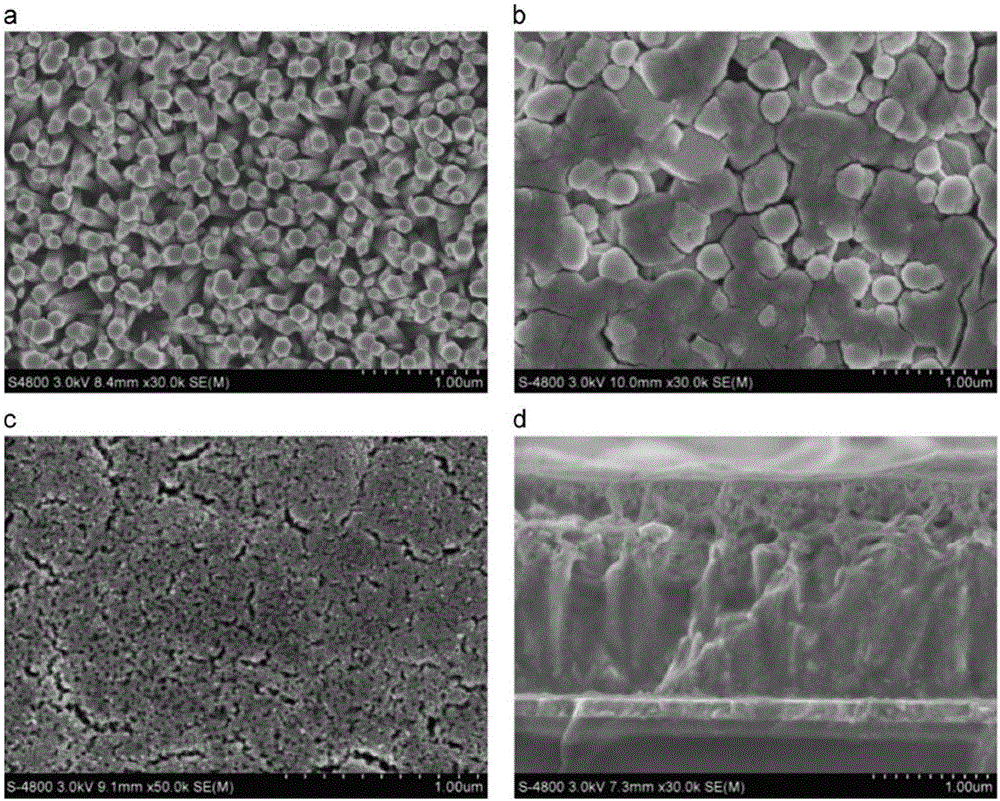

[0038] S1. Growth of ZnO nanorods

[0039] Dissolve zinc acetate in an ethanol solution to make a ZnO seed precursor with a concentration of 20mM, spin-coat the ITO glass substrate at a speed of 2000rpm. for 30s at ambient temperature, and place the ITO glass substrate in a Heat on the heating plate for 5~12min, then hang it upside down in a reaction vessel filled with an aqueous solution of zinc nitrate (75mM) and hexamethylenetetramine (50mM), heat and react at 90°C for 3 hours, then remove from the growth solution , rinsed with ethanol and deionized and then dried to obtain ZnO nanorods.

[0040] Growth of S2, CdS coating layer

[0041] The precursor material of CdS was dissolved in the ethanol solution of cadmium nitrate tetrahydrate (0.5M) and thiourea (0.5M), and spin-coated on the surface of ZnO nanorods at the speed of 2000rpm. Place on a heating plate at 90°C and heat until a thin yellow film is fo...

Embodiment 2

[0050] Follow the steps below to prepare ZnO nanorod photoanodes:

[0051] S1. Growth of ZnO nanorods

[0052] Dissolve zinc acetate in an ethanol solution to make a ZnO seed precursor with a concentration of 15mM. Spin-coat on the ITO glass substrate at a speed of 2000rpm. at ambient temperature for 30s, and place the ITO glass substrate on a heating plate at 180°C Heated above for 12min, then turned upside down and suspended in a reaction vessel filled with an aqueous solution of zinc nitrate (70mM) and hexamethylenetetramine (60mM), heated and reacted at 100°C for 2 hours, removed from the growth solution, and washed with ethanol and After deionized washing and drying, ZnO nanorods were obtained.

[0053] Growth of S2, CdS coating layer

[0054] Dissolve the precursor material of CdS in the ethanol solution of cadmium nitrate tetrahydrate (0.3M) and thiourea (1M), and spin-coat the surface of ZnO nanorods at a speed of 2000rpm. at ambient temperature for 30s, and place th...

Embodiment 3

[0058] Follow the steps below to prepare ZnO nanorod photoanodes:

[0059] S1. Growth of ZnO nanorods

[0060] Dissolve zinc acetate in an ethanol solution to make a ZnO seed precursor with a concentration of 30mM, spin-coat the ITO glass substrate at a speed of 2000rpm. for 30s at ambient temperature, and place the ITO glass substrate on a heating plate at 220°C Heated for 6 minutes, then turned upside down and suspended in a reaction vessel filled with an aqueous solution of zinc nitrate (90mM) and hexamethylenetetramine (80mM), heated at 82°C for 4 hours, removed from the growth solution, and washed with ethanol and After deionized washing and drying, ZnO nanorods were obtained.

[0061] Growth of S2, CdS coating layer

[0062] The precursor material of CdS was dissolved in the ethanol solution of cadmium nitrate tetrahydrate (0.6M) and thiourea (0.3M), and spin-coated on the surface of ZnO nanorods at the speed of 2000rpm. Place on a heating plate at 90°C and heat until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com