Ag2ZnSnS4/Mo structure photo-anode with visible-light response, preparation method of photo-anode and application of photo-anode

A structured light and visible light technology, applied in chemical instruments and methods, electrodes, chemical/physical processes, etc., to achieve the effect of excellent photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

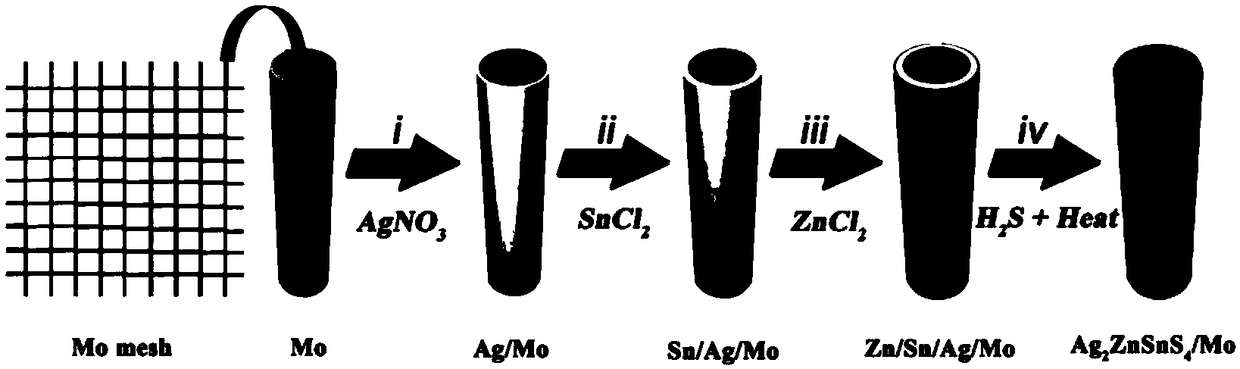

[0054] Example 1 Ag 2 ZnSnS 4 Preparation of / Mo structured photoanode

[0055] (1) Ultrasonic cleaning of molybdenum mesh:

[0056] First use 5mol / L concentrated hydrochloric acid and 5mol / L concentrated sodium hydroxide solution to ultrasonically clean for 1.0 hours (frequency 40KHz), then use acetone, deionized water and ethanol to ultrasonically clean for 1.0 hour (frequency 40KHz), after ultrasonic cleaning The surface of molybdenum mesh presents a metallic luster.

[0057] (2) Deposit metal Ag:

[0058] First configure 100ml of 0.01mol / L silver nitrate solution, and then deposit metallic silver on the molybdenum grid by controlling the deposition voltage and deposition charge. The deposition voltage is 0.0V Vs SCE (calomel electrode), and the deposition charge is 0.8C / cm 2 , to obtain the Ag / Mo precursor.

[0059] (3) Deposit metal Sn:

[0060] First configure the 0.02mol / L stannous chloride solution of 100ml, then deposit metal tin on the Ag / Mo net by control...

Embodiment 2

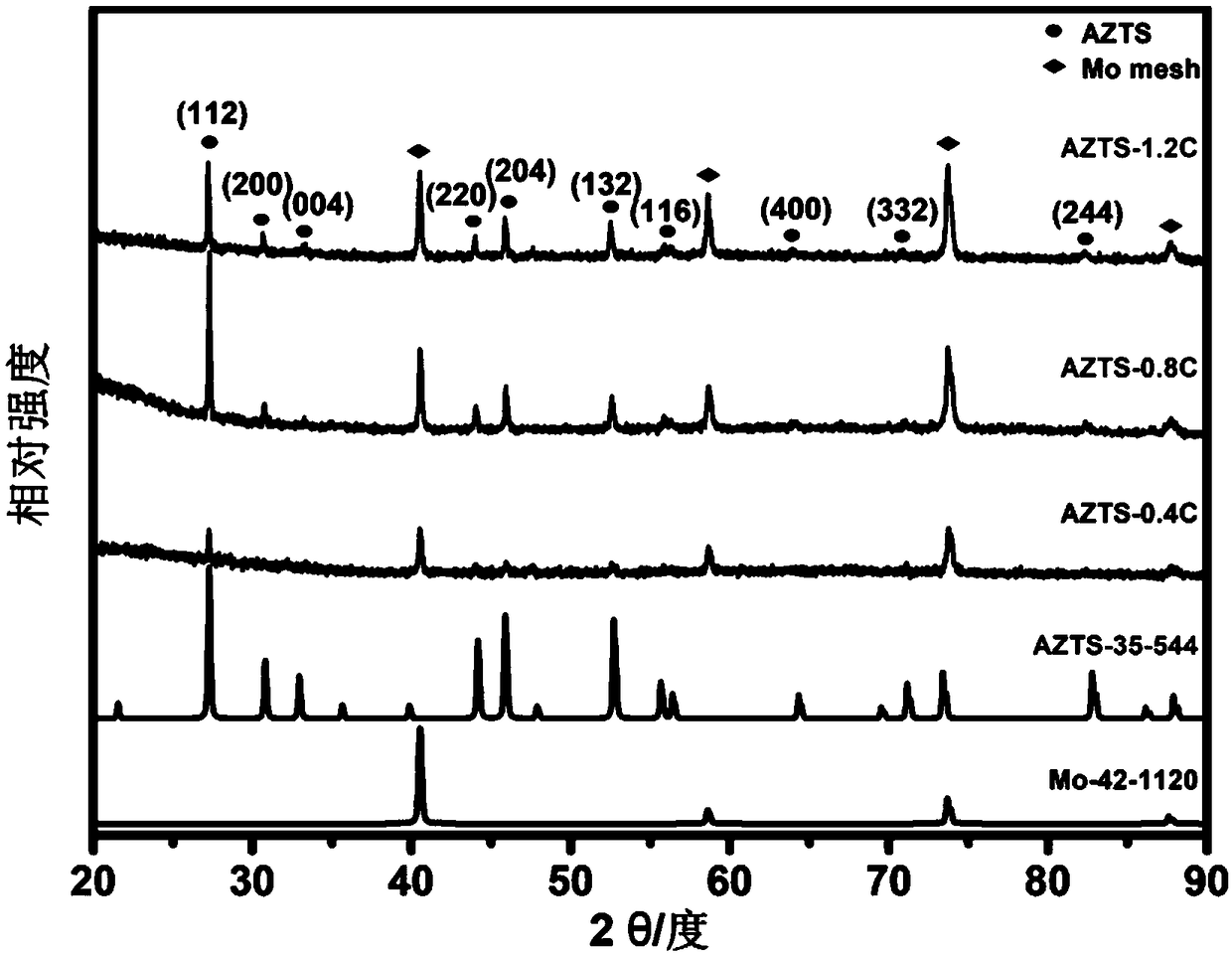

[0065] Example 2 Ag with different Zn / Sn / Ag deposition charges 2 ZnSnS 4 Preparation of / Mo structured photoanode This example prepares Ag with different Zn / Sn / Ag deposition charges 2 ZnSnS 4 / Mo structure photoanode, prepared 2 kinds of photoanodes altogether, its preparation method is the same as embodiment 1, difference is: the first kind is to deposit these three kinds of metal elements in step (2)(3)(4) in embodiment 1 The simultaneous reduction of charge is: 0.4C / cm 2 (Ag), 0.8C / cm 2 (Sn), 0.8C / cm 2 (Zn); the second is to increase the amount of these three kinds of metal element deposition charge in step (2) (3) (4) in embodiment 1 while being: 1.2C / cm 2 (Ag), 2.4C / cm 2 (Sn), 2.4C / cm 2 (Zn). However, these two Ag 2 ZnSnS 4 The ratio of deposited charges in the Zn / Sn / Ag precursor in the / Mo structured photoanode remains 2.0:2.0:1.0.

[0066] Schematic diagram of a synthetic photoanode:

[0067] Embodiment 1 and 2 prepare Ag 2 ZnSnS 4 The specific steps of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com