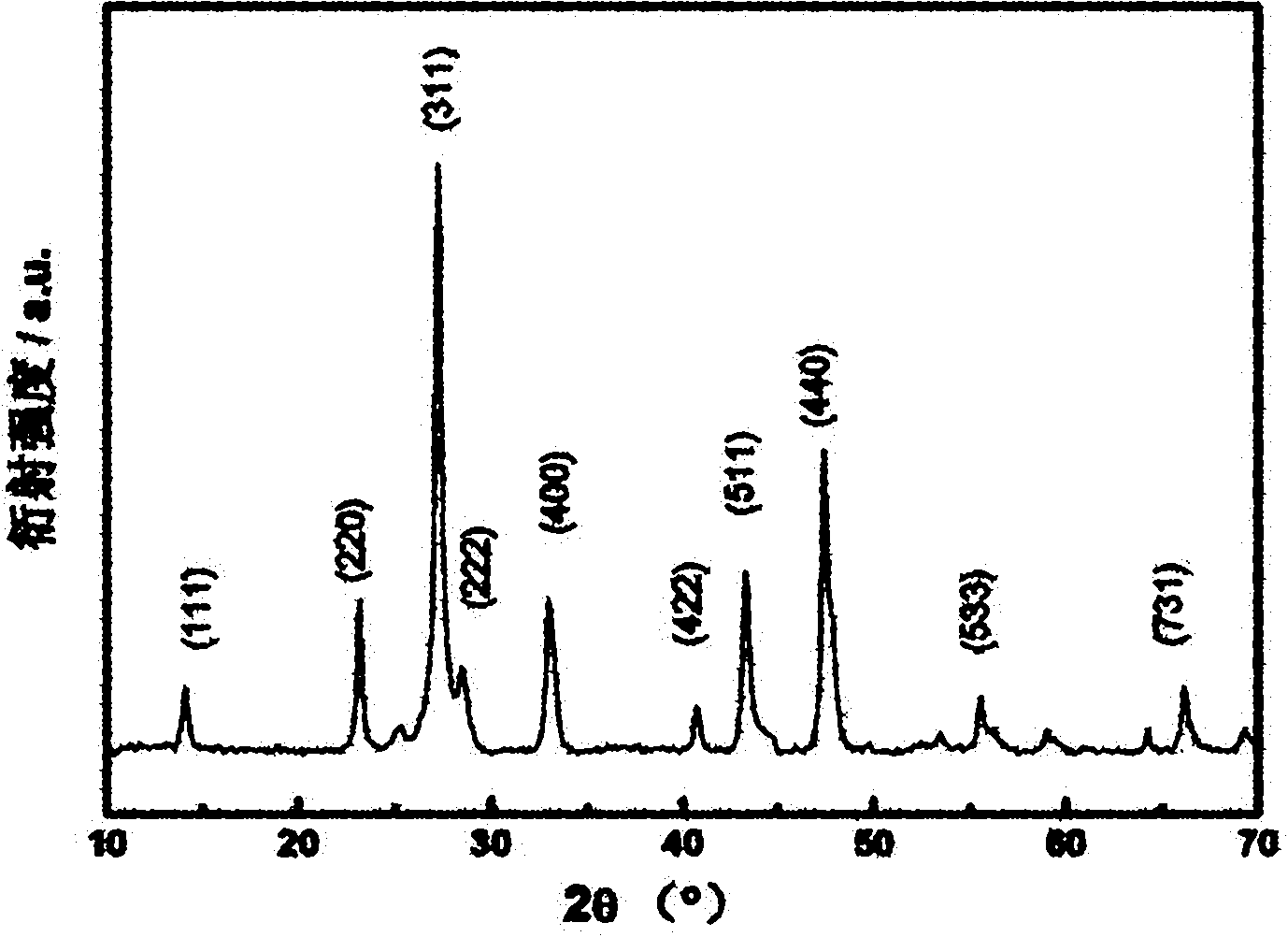

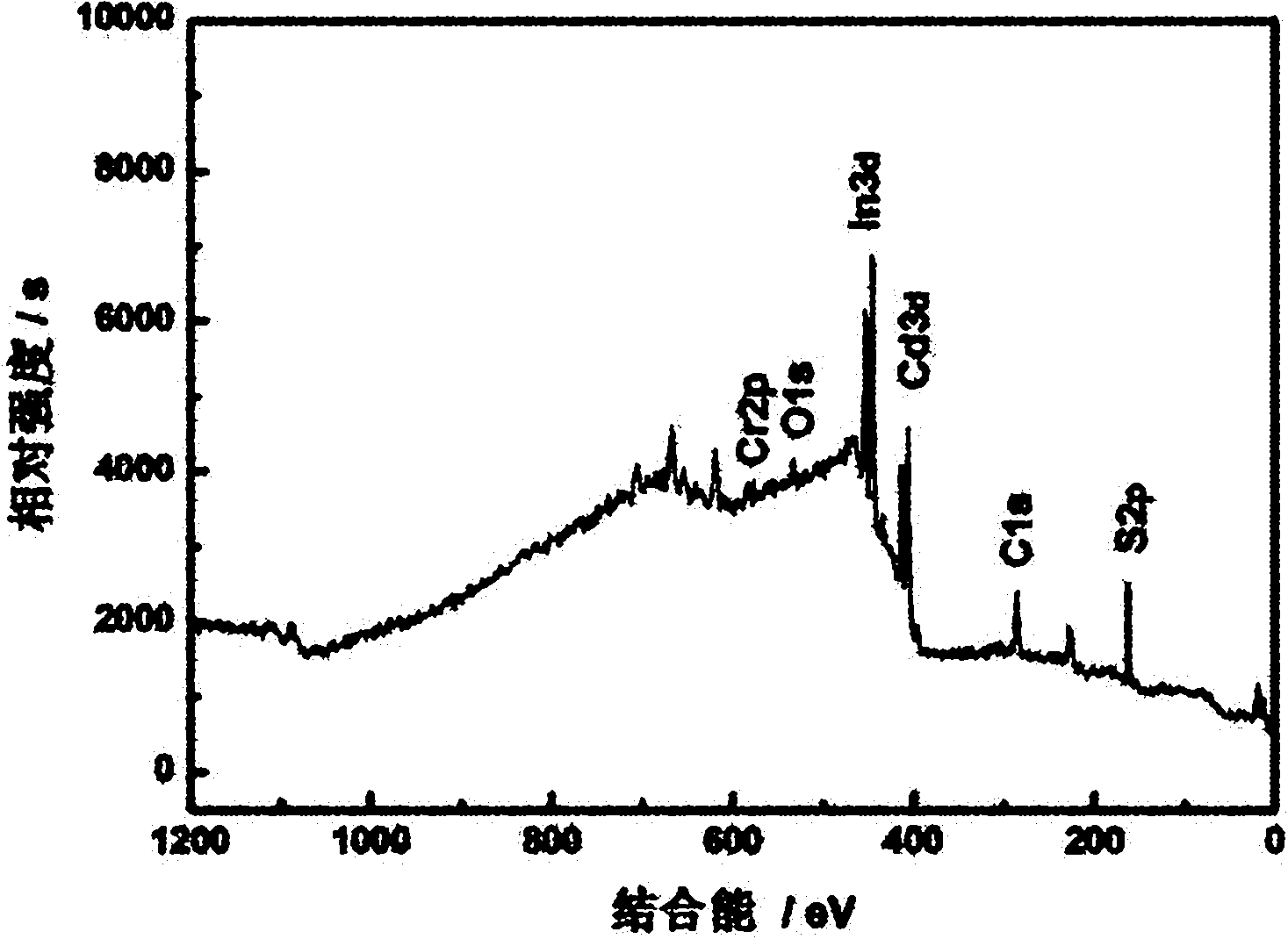

Method for preparing transition metal ion-doped porous CdIn2S4 photocatalyst

A technology of transition metal ions and photocatalysts, which is applied in the field of preparation of ion-doped porous CdIn2S4 photocatalysts, can solve the problems of low photocatalytic activity of photocatalysts, achieve simple operation, good crystallinity and chemical stability, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

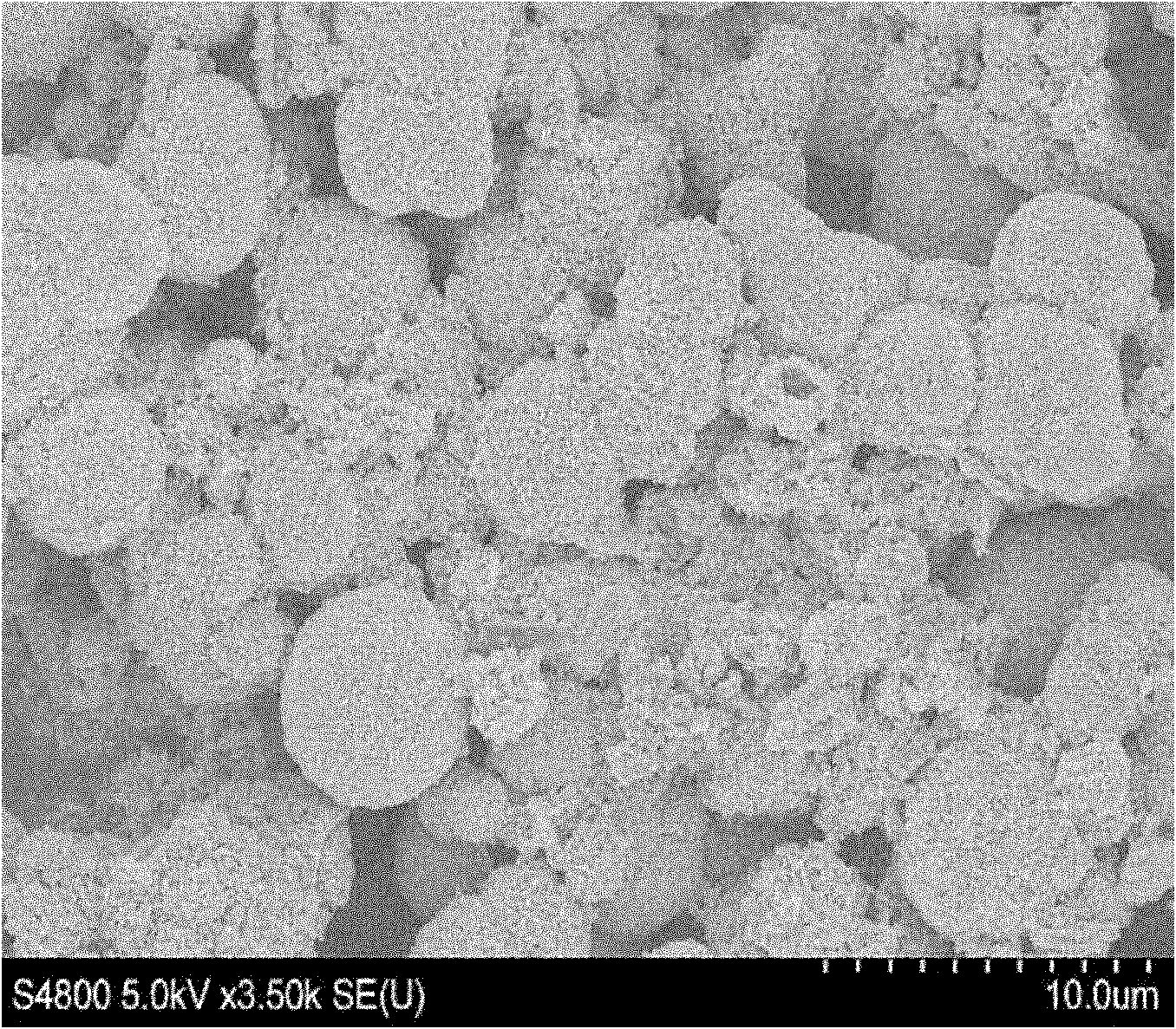

specific Embodiment approach 1

[0010] Specific implementation mode 1: This implementation mode transition metal ion doping porous CdIn 2 S 4 The preparation method of photocatalyst, carries out as follows: one, divalent cadmium salt, trivalent indium salt and thioacetamide are dissolved in water or non-aqueous solvent, and the mol ratio of Cd, In and S is 1: 2: 8. The molar ratio of divalent cadmium salt to water or non-aqueous solvent is 1:2000, then add template agent, the concentration of template agent is 6.8×10 -3 ~5.6×10 -2 mol / L, at 35°C, use 50KHz ultrasonic treatment for 5-10min until completely dissolved; 2. Then add transition metal salt, the mass of transition metal salt is 0.1%-5.0% of the mass of divalent cadmium salt, and then at 30-80°C Under ultrasonic treatment for 20-40min, the ultrasonic frequency is 50-99KHz, and a yellow colloidal precipitate is obtained; 3. Transfer the yellow colloidal precipitate to a polytetrafluoroethylene-lined autoclave, and heat-treat at 120-200°C for 6- 24h...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the concentration of template agent in step one is 1×10 -2 ~5×10 -2 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the concentration of template agent in step one is 2×10 -2 ~3×10 -2 mol / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com