Technology for preparing high-purity nitrogen trifluoride by purifying nitrogen trifluoride through rectification and adsorption

A nitrogen trifluoride, high-purity technology, applied in the direction of nitrogen and non-metallic compounds, can solve problems such as environmental pollution, and achieve the effect of convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

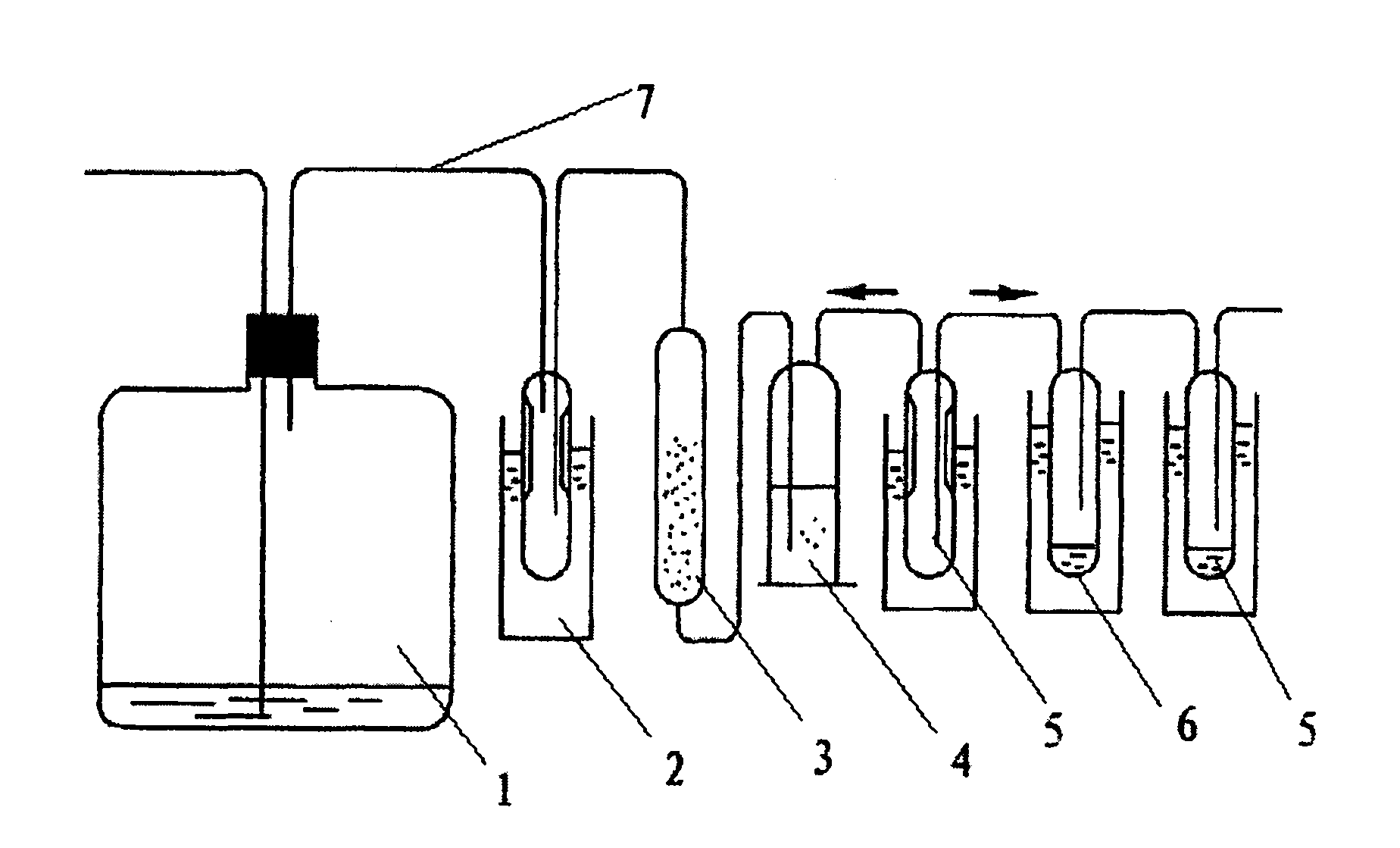

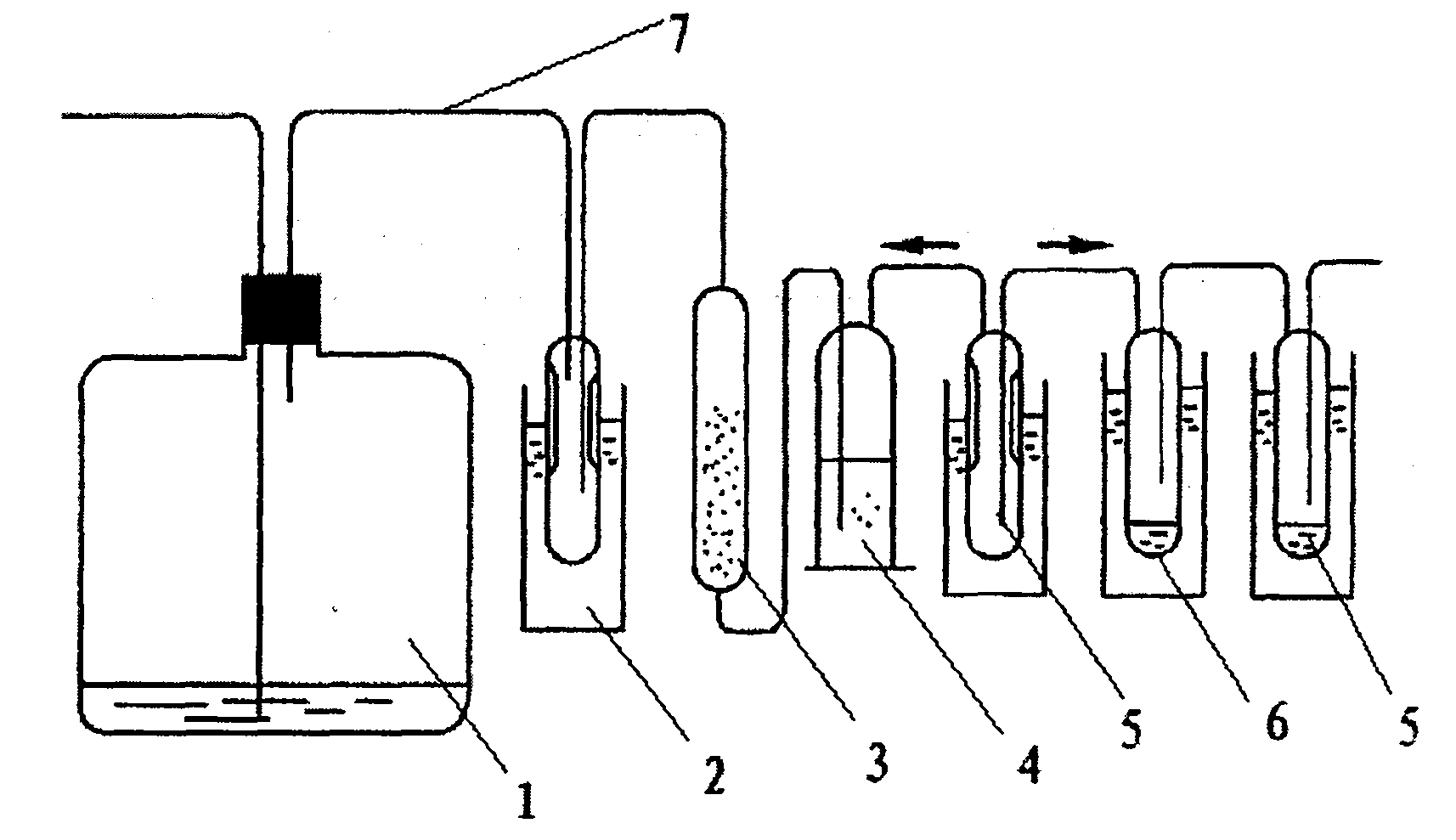

[0010] refer to figure 1 , glass bottle 1, water trap 2, sodium peroxide filled tower 3, sodium thiosulfate solution bottle 4, oxygen trap 5 in the air, nitrogen trifluoride trap 6 through the connecting pipeline 7 according to its system function Assembled into one body.

[0011] Nitrogen trifluoride purification system technical process: the anode gas crude nitrogen trifluoride obtained by electrolysis mainly contains nitrogen, oxygen, carbon monoxide, carbon dioxide, nitrous oxide, difluorohydrazine, tetrafluorohydrazine, carbon tetrafluoride, six Sulfur fluoride, silicon tetrafluoride, fluorine gas, hydrogen fluoride, water and other impurities. To remove these impurities, the anode gas was passed through a copper trap cooled to -78°C with methanol-dry ice, and then passed through a sodium fluoride tube heated to 100°C to remove hydrogen fluoride. Oxygen is adsorbed with activated carbon at low temperature. Put the crude nitrogen trifluoride into a 20L glass bottle 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com