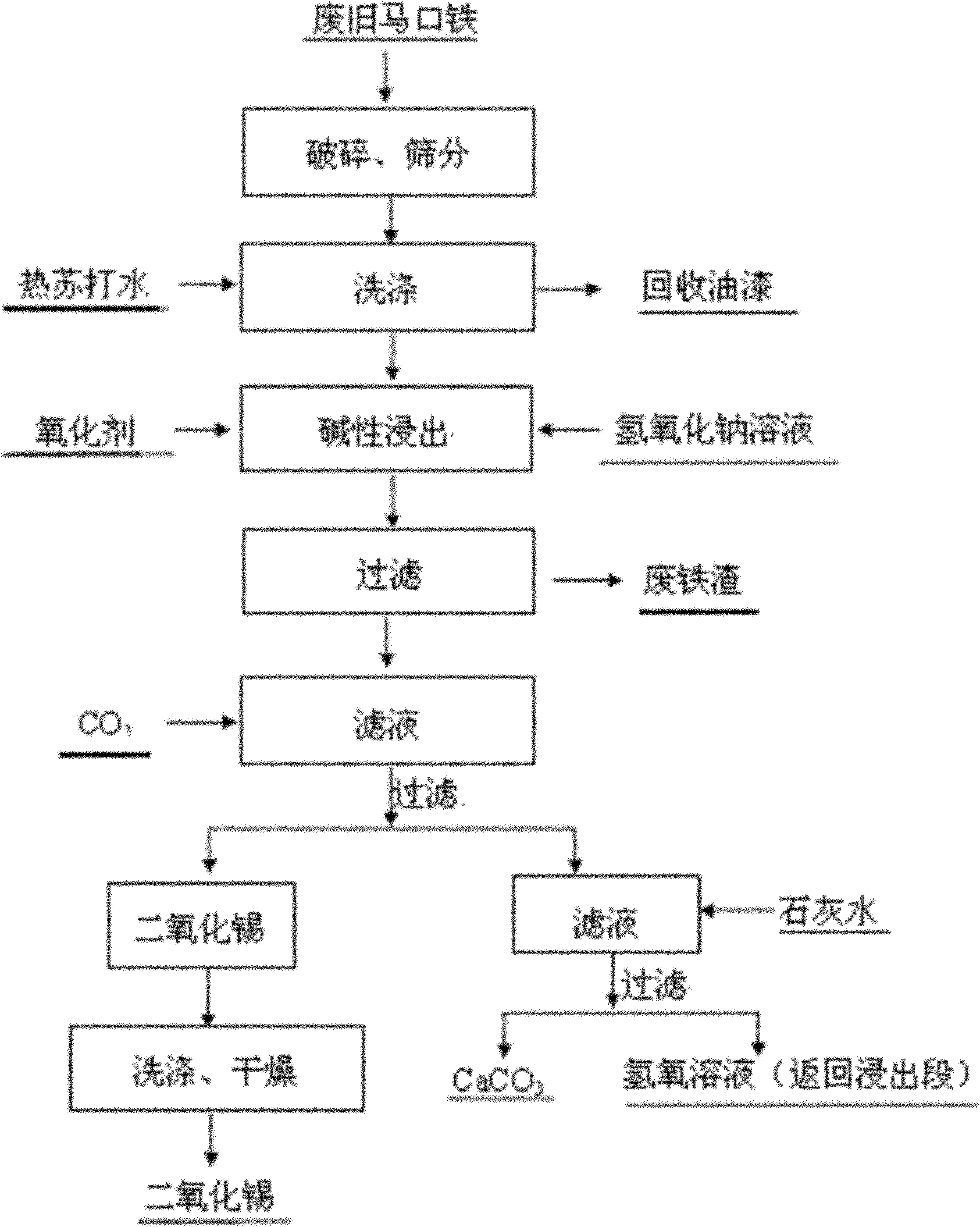

Method for separating tin from waste tinplate and preparing tin dioxide

A tin dioxide and tinplate technology, applied in the direction of improving process efficiency, can solve the problems of difficult operation, environmental pollution and high equipment cost, and achieve the effects of low pollution, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After crushing waste tinplate with a vertical high-speed rotary pulverizer, weigh 500 g of the 60-mesh sieve, wash with 2 liters of 5% hot soda aqueous solution for 30 minutes, the temperature of the hot soda aqueous solution is 60 ° C, and analyze the main components of the filter residue after washing The result is as follows:

[0031] element

sn

Fe

Cu

Pb

Sb

paint

wt%

2.25

97.64

0.06

≤0.01

≤0.01

0.02

[0032] More than 93% of the paint can be removed through the hot soda aqueous solution, and 2% of tin is lost, and the paint in the filtrate can be recycled.

[0033] Take 400g of filter residue, add it to 200ml of 20% concentration sodium hydroxide solution, heat to 70°C, keep a certain stirring intensity, then add 3% sodium nitrate of filter residue weight as oxidant, react for 4 hours, filter to obtain sodium stannate filtrate, analyze the filtrate The main ingredients are as...

Embodiment 2

[0039] After crushing waste tinplate with a vertical high-speed rotary pulverizer, weigh 500 g of 100-mesh sieve, wash with 2 liters of 8% hot soda aqueous solution for 30 minutes, and the temperature of the hot soda aqueous solution is 50 ° C. After filtering and washing, take the filter residue 400g, add in 180ml25% concentration sodium hydroxide solution, heat to 60 ℃, keep certain stirring strength, then add 3% potassium chlorate of filter residue weight as oxidant, react for 4 hours, filter to obtain sodium stannate filtrate, analyze the main components of the filtrate as follows :

[0040] element

sn

Fe

Cu

Pb

Sb

paint

g / L

49.45

≤0.01

≤0.01

≤0.01

≤0.01

≤0.01

[0041] After leaching with sodium hydroxide + potassium chlorate, the leaching rate of tin is 98.9%.

[0042] Pass carbon dioxide gas into the above-mentioned filtrate, the consumption of carbon dioxide gas is 40 times of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com