Device for monitoring content of organic matters in circulating water in anti-explosion area on line

A monitoring device, a technology for organic matter, which can be used in measuring devices, by measuring the acceleration and deceleration rates of fluids, and using liquid/vacuum for liquid tightness measurement, etc. and other problems to achieve the effect of ensuring normal operation, avoiding low temperature freezing, and easy on-site maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

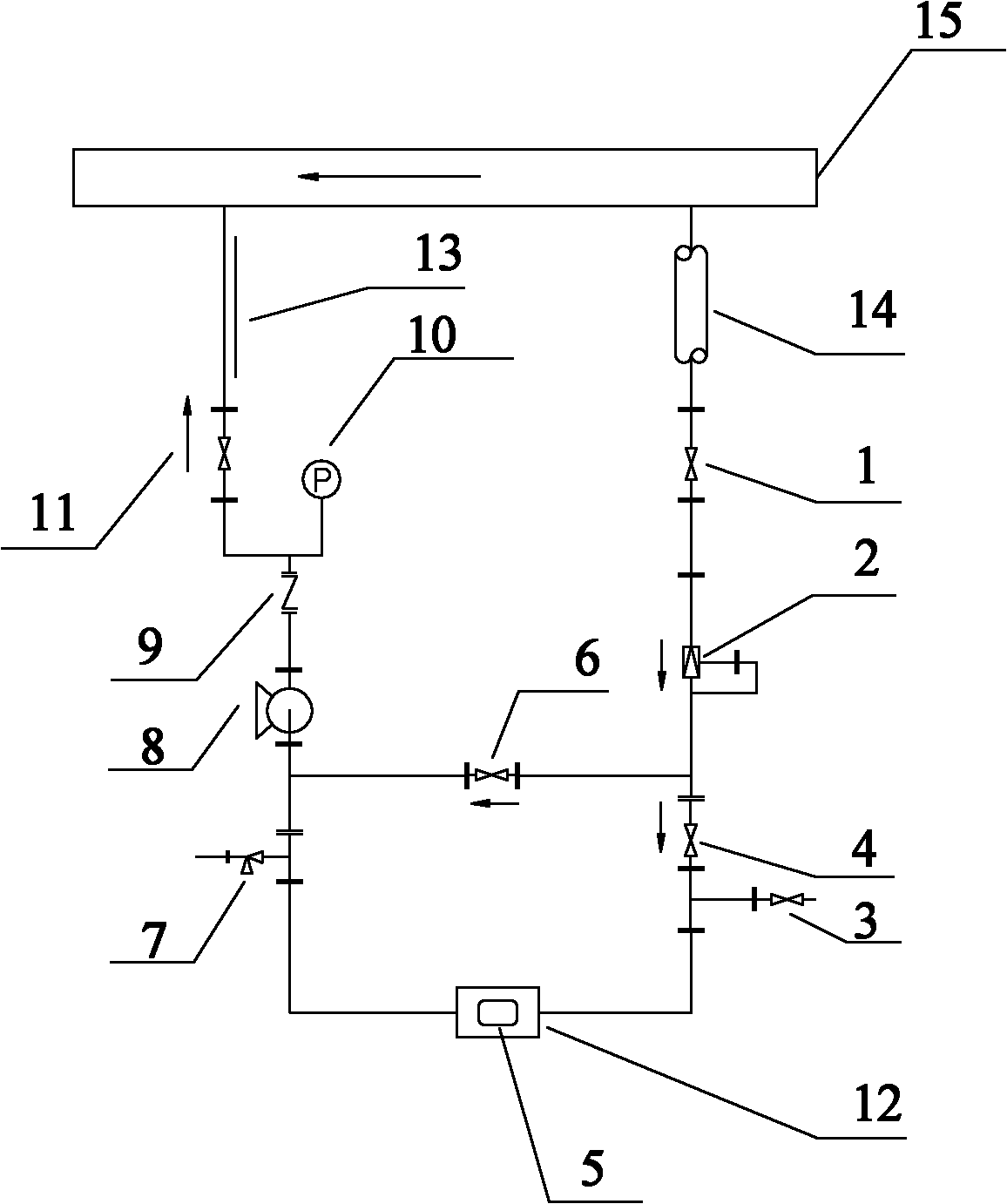

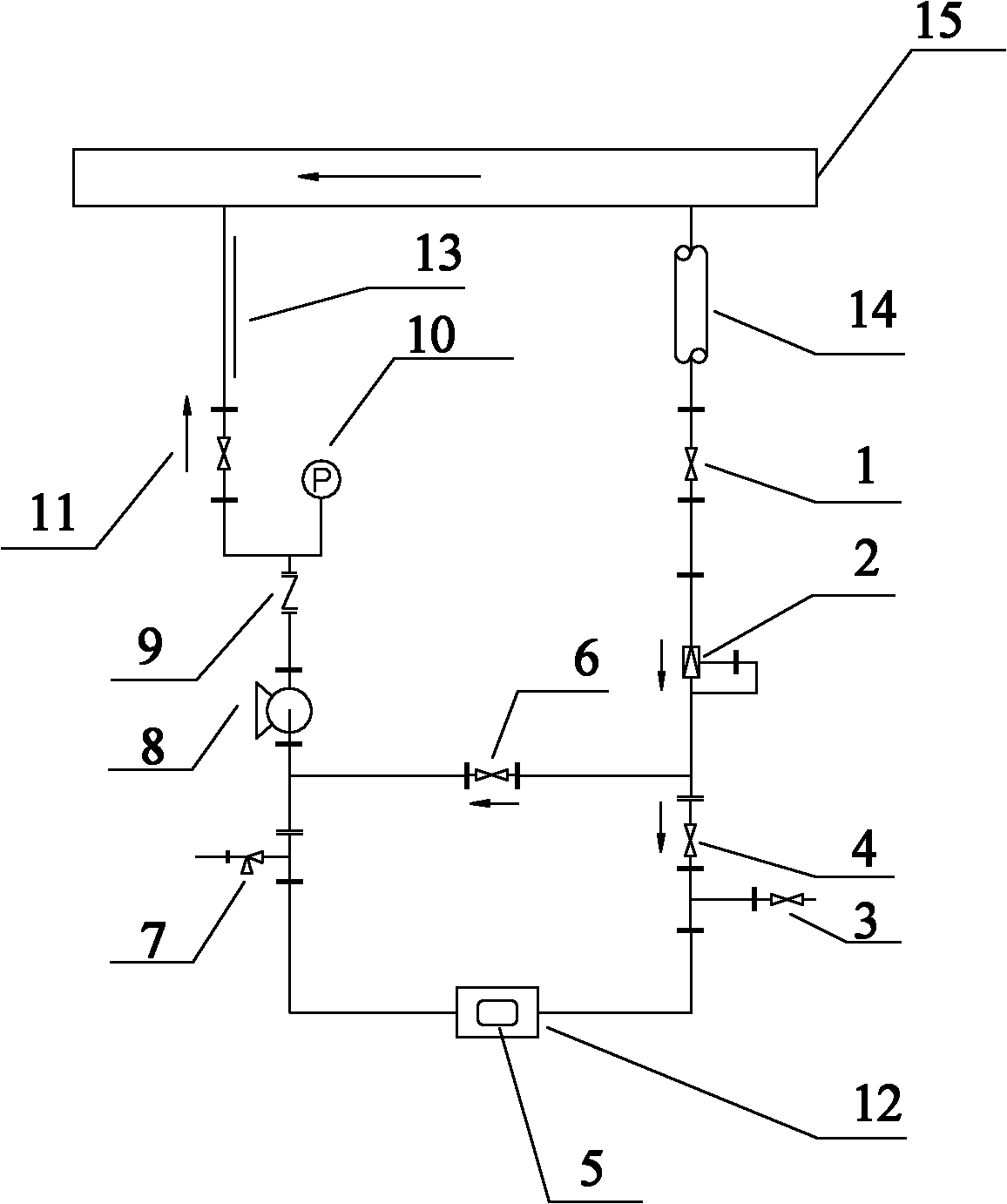

[0030] Example 1: The pressure of the circulating water pipeline in a styrene workshop is 0.2Mpa. There may be lubricating oil in the water pipeline when a leakage accident occurs. This device is installed in the circulating water pipeline, and a set of optical fiber online monitor (output signal 4-20mA) is installed. The outlet head of the centrifugal pump is 30m, the rated current is 2.5A, the outlet pressure of the pressure reducing valve is less than 0.04Mpa, the discharge pressure of the safety valve is 0.06Mpa, and the rated current of the electric heat tracing is 2A.

[0031] The results of monitoring for 90 days show that the online monitoring device is operating normally, the sampling system has no leakage when it is stopped, and it works normally after it is turned on. The reading of the optical fiber monitor has been stable at about 30ppm, indicating that there is lubricating oil in the water in the pipeline, and there is a leakage accident. .

Embodiment 2

[0032] Example 2: The pressure of the circulating water pipeline in a styrene workshop is 0.4Mpa. When a leakage accident occurs, there may be styrene monomer in the water pipeline. This device is installed in the circulating water pipeline, and a set of ultraviolet fluorescence online monitor (output signal 4~ 20mA), the outlet lift of multistage centrifugal pump is 50m, the rated current is 2.7A, the outlet pressure of pressure reducing valve is less than 0.06Mpa, the discharge pressure of safety valve is 0.1Mpa, and the rated current of electric heat tracing is 2A.

[0033] The results of monitoring for 60 days showed that the online monitoring device was working normally, and the reading of the ultraviolet fluorescence monitor was stable and close to zero, indicating that there was no styrene monomer in the water in the pipeline, and no leakage accident occurred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com