Microporous filter cloth filtering machine

A technology of filter cloth and filter cavity, which is applied in the field of microporous filter cloth filter, can solve the problems of high hardness and sealing requirements of filter fan support, large volume of disc filter equipment, and high power of rotating drum motor. Achieve the effect of increasing the effective filtering area, reducing the strength, and reducing the power of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

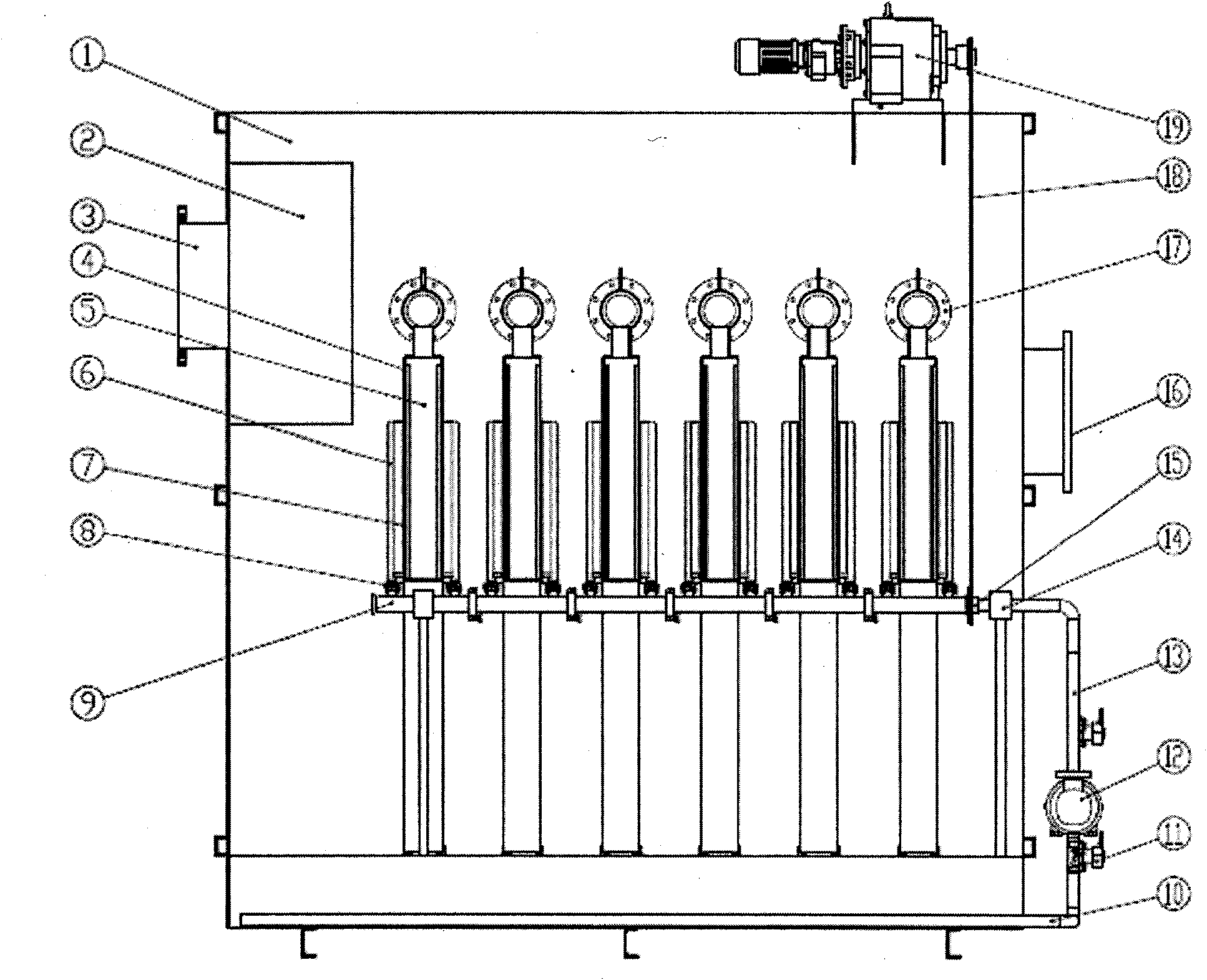

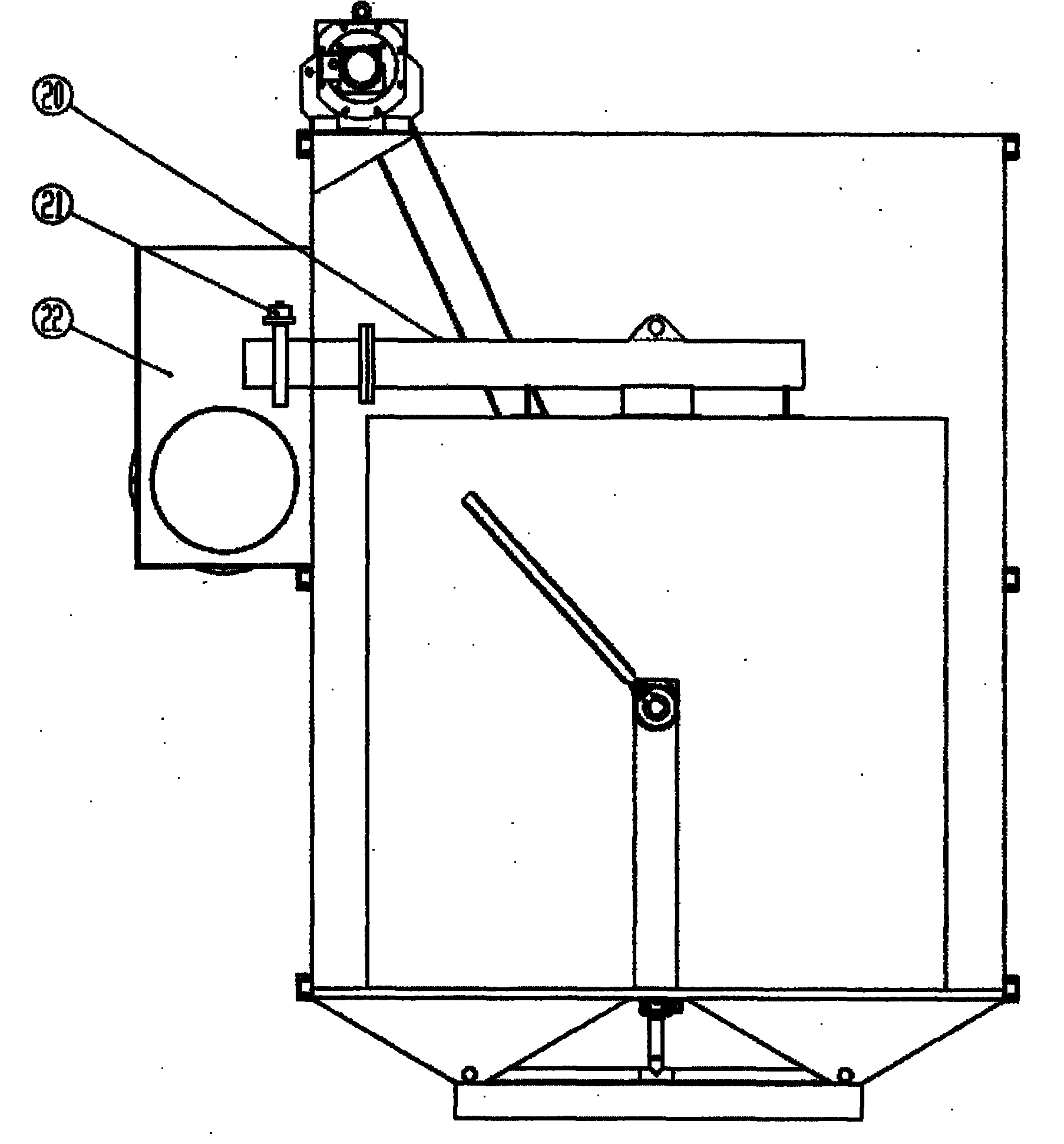

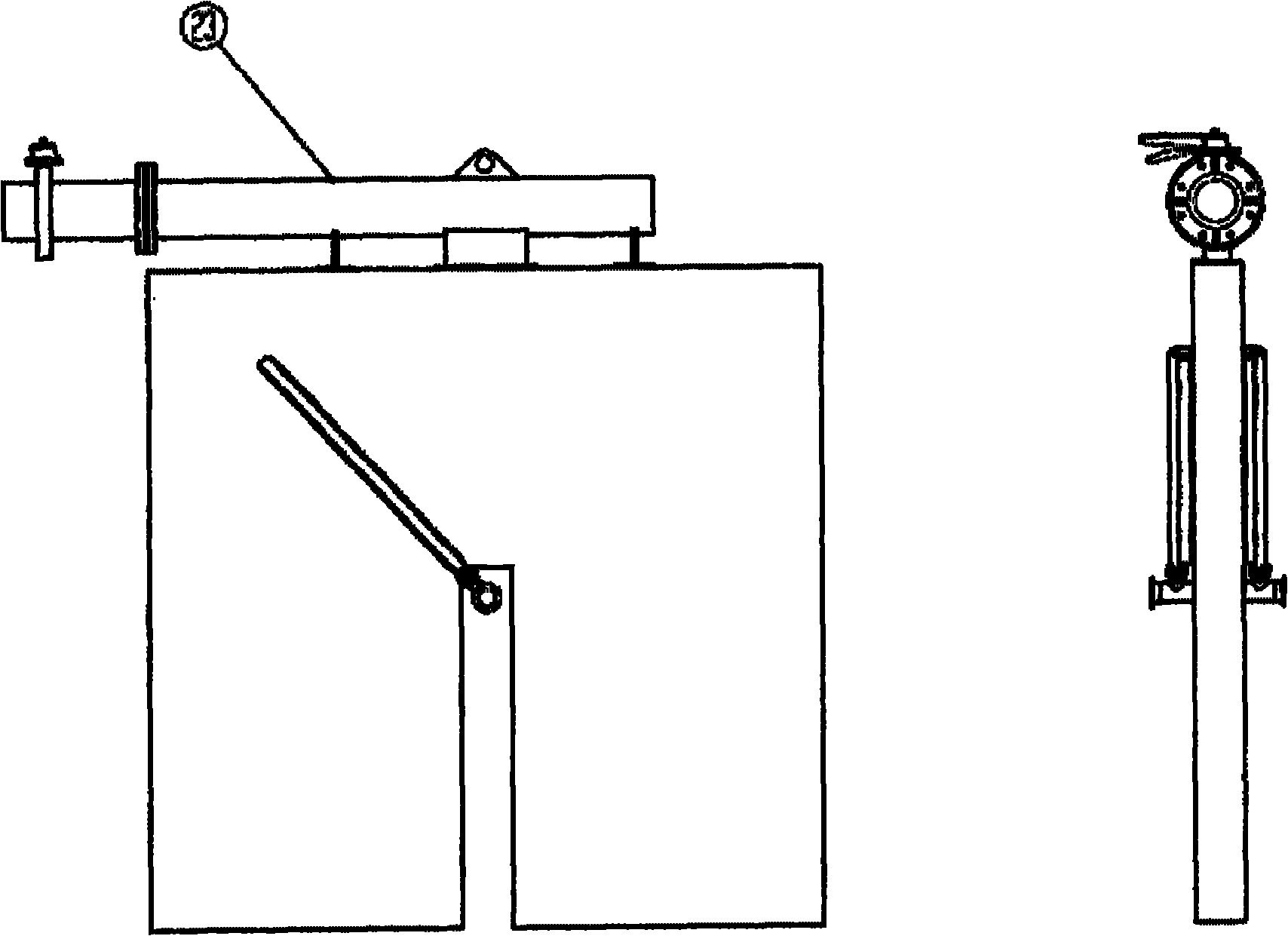

[0021] The microporous filter cloth filter machine that the present invention proposes for sewage filtration, as figure 1 , figure 2 with image 3 As shown, it includes box body 1, water inlet weir 2, water inlet 3, filter cloth 4, filter cloth frame 5, suction cup assembly 6, filter chamber 7, suction cup and sewage suction pipe unit connector 8, filter sewage suction pipe unit 9. Sewage suction pipe at the bottom of the tank 10, sewage suction pump 12, back suction main pipeline 13, end support of sewage suction pipe 14, transmission sprocket 15, filtered clean water outlet 16, outlet branch pipe flange 17, transmission chain 18, drive Motor 19, water outlet branch pipe 20, butterfly valve 21, clear water weir 22, filter unit 23. A water inlet 3 is provided on the top of one side of the microporous cloth filter box body 1 , and the water inlet is connected to the water inlet weir 2 . The circular filter cloth 4 is fixed on both sides of the rectangular filter cloth frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com