Biological treatment method of oilfield drilling waste

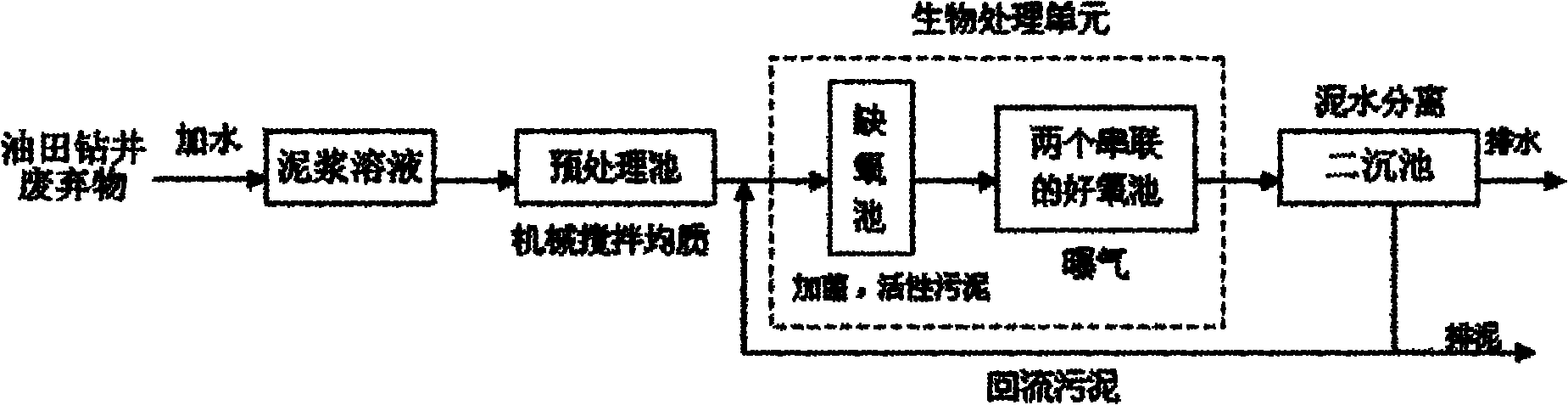

A drilling waste and biological treatment technology, which is applied in biological sludge treatment, sludge treatment, aerobic and anaerobic process treatment, etc., can solve the problems of limited degradation effect, long time required for biological treatment, difficult biodegradation, etc. , to achieve the effect of low treatment cost, favorable heat preservation and enhanced biological treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

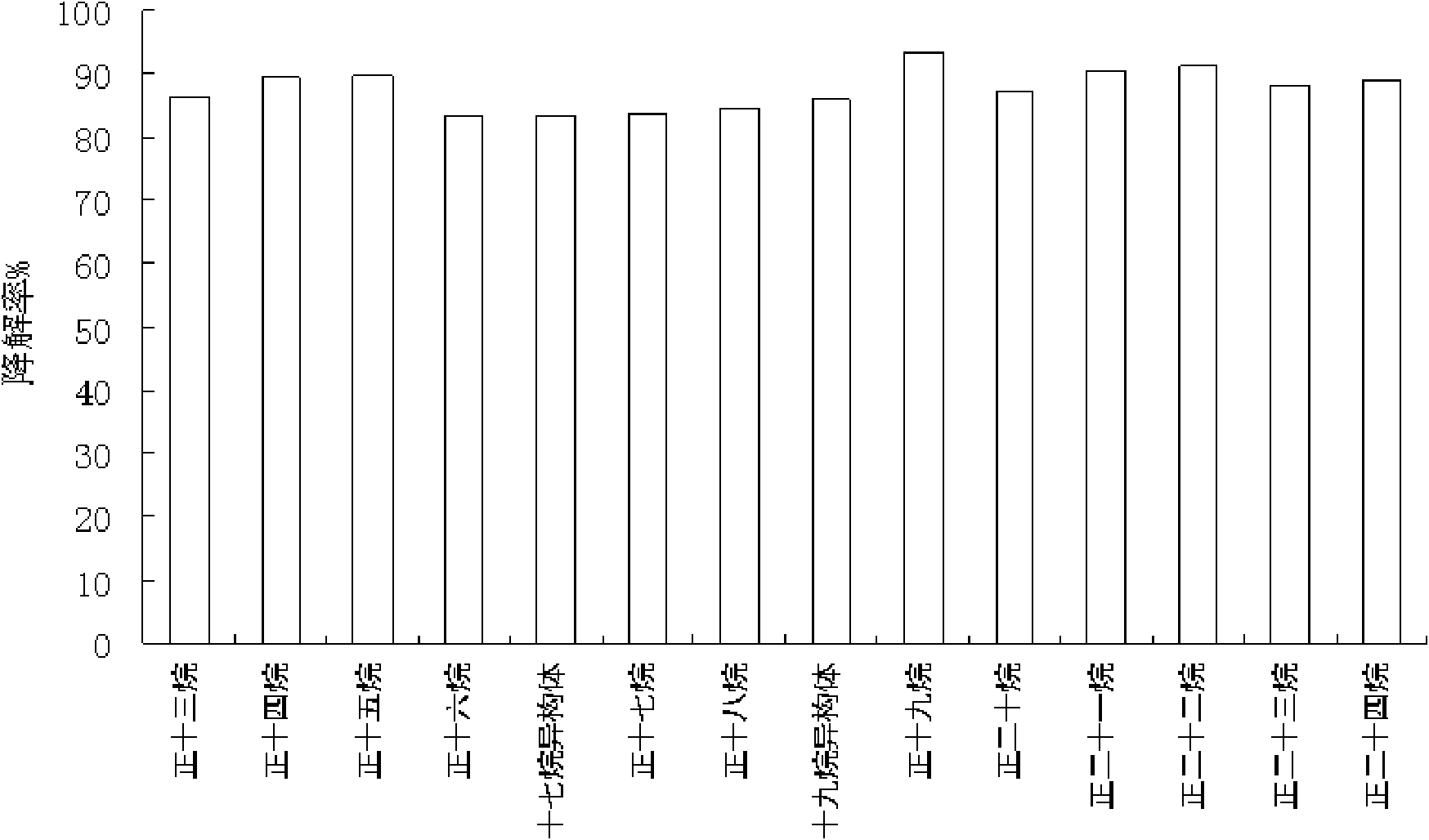

Examples

Embodiment 1

[0033] (1) 45g of drilling waste (water content of 67.23%; dry sample containing 60.56% ash, 32.91% volatile solids, and 2.14% fixed carbon) from Pinghu Bajiaoting No. B01 well was mixed with 100mL of water Mix in a glass container, and add nitrogen, phosphorus, magnesium and iron nutrient salts according to the weight ratio of COD:N:P:Mg:Fe=100:5:1:0.05:0.05, to prepare drilling waste mud solution for domestication;

[0034] (2) Get 2L of activated sludge (MLSS=5.0g / L) from the sewage treatment system of Shanghai Water Purification Plant to domesticate in the laboratory sequencing batch reactor (SBR), and the effective volume of SBR is 2L;

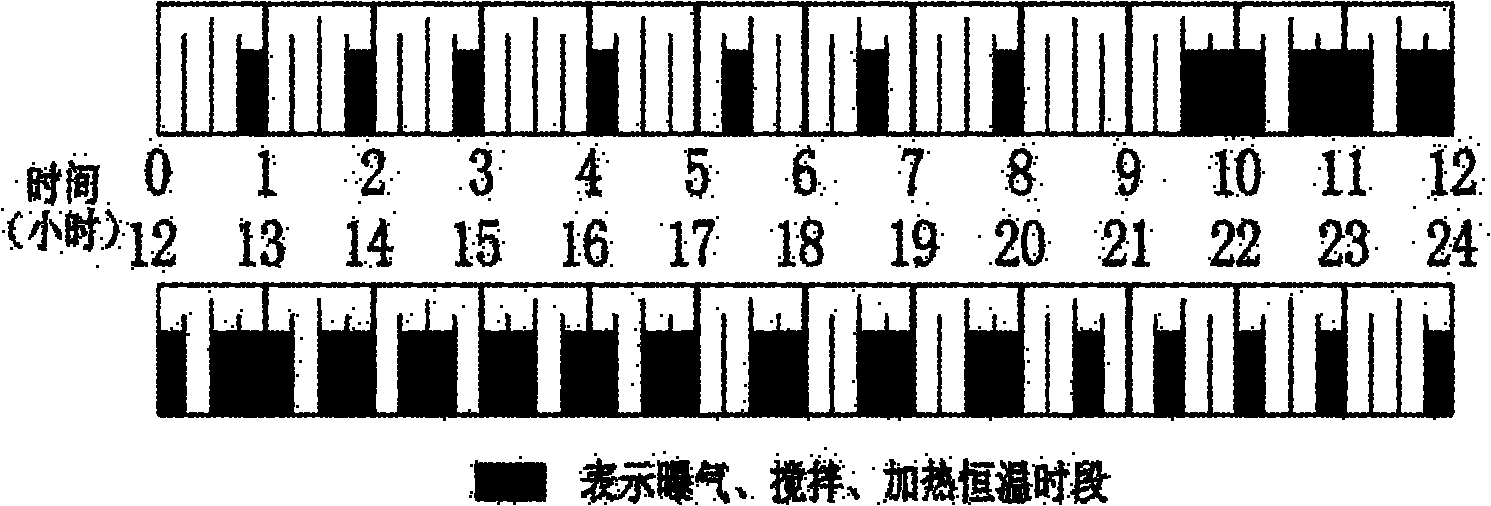

[0035] In the acclimatization stage, the designed COD of SBR is 500mg / L, which is jointly provided by glucose and diesel oil or drilling waste; during the operation of the SBR process, a timer is used to control the aeration / stirring / heating time.

[0036] In the first domestication stage, commercially available 0# diesel was used and glu...

Embodiment 2

[0048] (1) Add 0.16g K 2 HPO 4 , 0.08g NaH 2 PO 4 , 0.04g anhydrous MgSO 4 , 0.02g anhydrous CaCl 2 , 0.04g NaCl and 0.4g NH 4 Cl was uniformly dissolved in 200ml of water, and sterilized in a sterilizing pot at 110°C for 2 hours, then cooled to room temperature to obtain an inorganic salt-enriched medium, which was stored in a refrigerator;

[0049] In the above-mentioned inorganic salt-enriched medium with a culture system of 50 ml, inoculate commercially available strains of Pseudomonas and Micrococcus at a ratio of 5% of the volume of the culture system, shake the flask at 30°C and 120rpm Cultured for 3 days. The enriched bacterial solution containing Pseudomonas and Micrococcus was stored at a low temperature at 4°C;

[0050] (3) 5 kilograms of drilling waste taken from Pinghu Bajiaoting No. B01 well and 5L water are mixed in the pretreatment tank to form a mud solution to be treated;

[0051] (4) Adopt JJ-1 precision booster electric agitator, with the stirring s...

Embodiment 3

[0057] (1) Add 0.16g K 2 HPO 4 , 0.08g NaH 2 PO 4 , 0.04g anhydrous MgSO 4 , 0.02g anhydrous CaCl 2 , 0.04g NaCl and 0.4g NH 4 Cl was uniformly dissolved in 200ml of water, and sterilized in a sterilizing pot at 110°C for 2 hours, then cooled to room temperature to obtain an inorganic salt-enriched medium, which was stored in a refrigerator;

[0058] In the above-mentioned inorganic salt-enriched medium with a culture system of 100ml, inoculate commercially available Achromobacter, Chromohalobacter and Halomonas bacterial strains at a ratio of 5% of the system volume, at 30°C, Shake flasks were cultured at 120rpm for 3 days. The enriched bacterial solution containing Achromobacter, Chromohalobacter and Halomonas was stored at a low temperature of 4°C;

[0059] (3) 2 kilograms of drilling waste taken from Pinghu Bajiaoting No. B01 well and 5L water are mixed in the pretreatment tank to form a mud solution to be treated;

[0060] (4) Adopt JJ-1 precision booster electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com