Waste paper deinking process method

A process method, waste paper deinking technology, applied in the direction of papermaking, textile and papermaking, cellulose pulp post-treatment, etc., can solve the problems of high paper dust, high content of fine stickies, high content of residual ink, etc., to achieve whitening The effect of high density, residual ink and sticky content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: U.S. waste 8#, national waste 8# and national waste 10# produce newsprint

[0031] A process for deinking waste paper, comprising the following steps: pulping, high-concentration sand removal, coarse screening, low-concentration sand removal, pre-flotation, fine screening, concentration, thermal dispersion, bleaching, post-flotation and pulping process, the waste paper is deinked pulp after the above process.

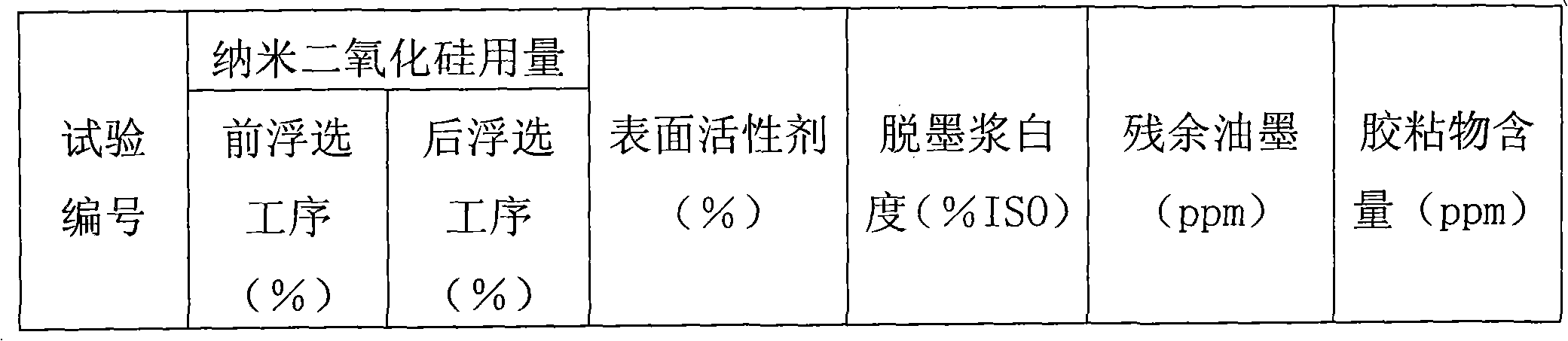

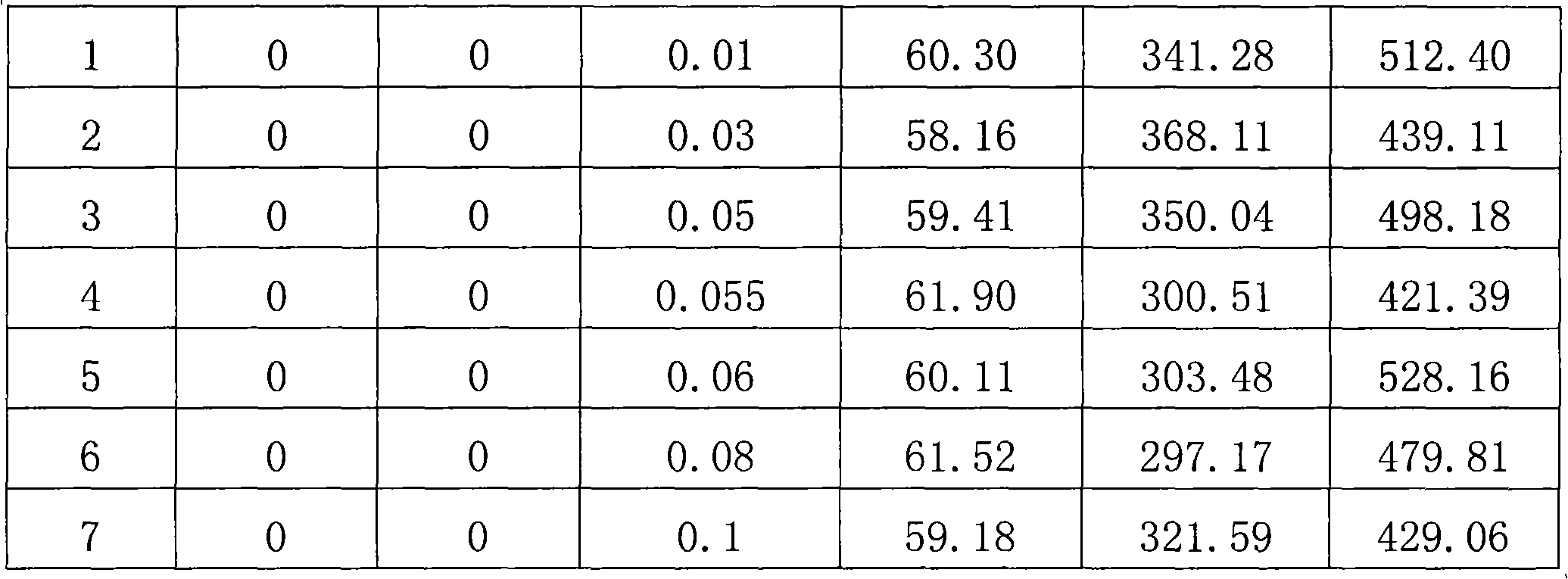

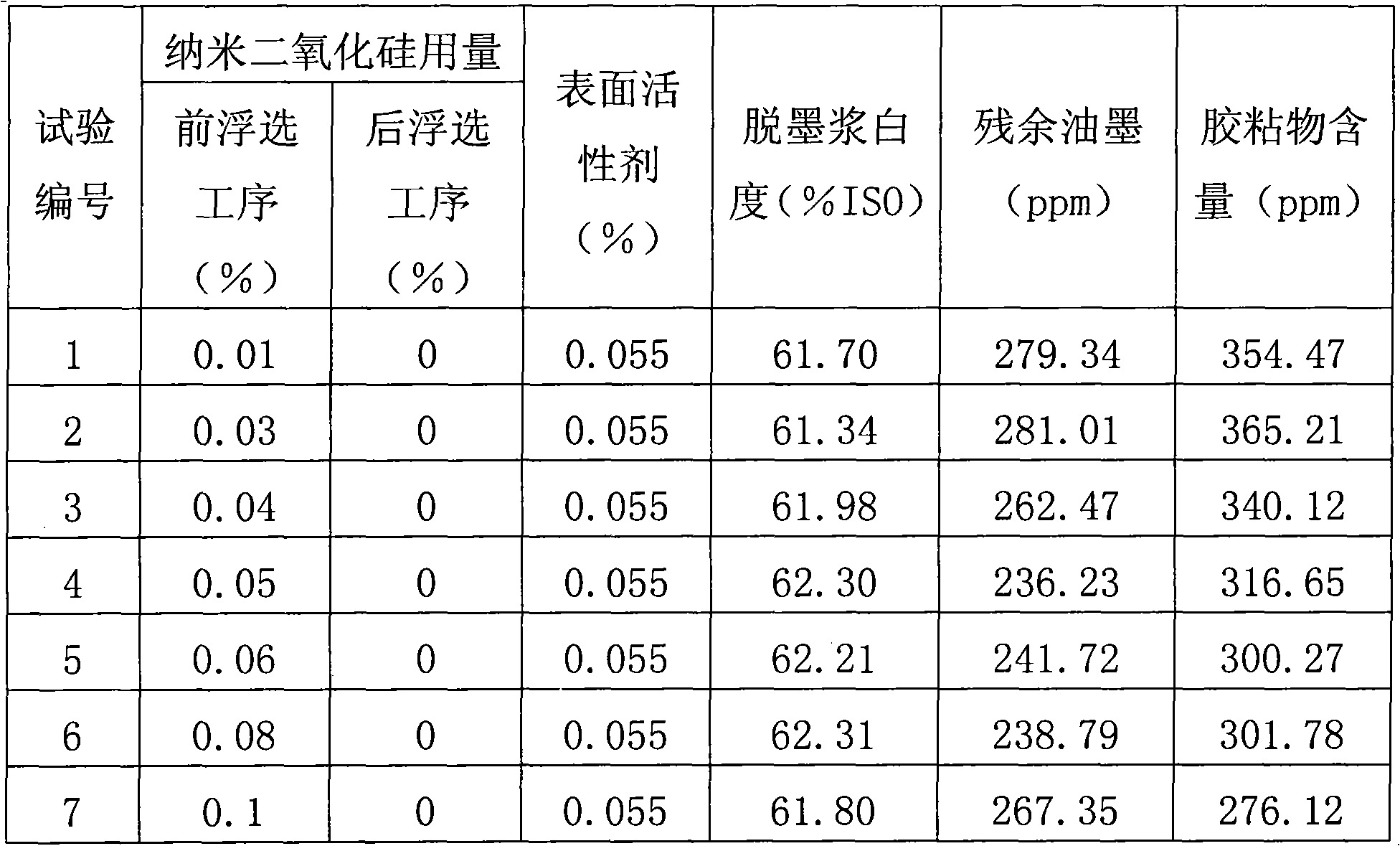

[0032] The pulping process is: put the waste paper and water in the drum pulper, add 0.1-0.8% deinking agent, 0.1-0.8% sodium silicate, 0.1-0.8% sodium hydroxide and 0.01-0.1% surfactant, the surfactant is anionic surfactant sodium α-alkenyl sulfonate, the pulping concentration is controlled at 3.0-20%, and the temperature is 20-70 °C, the pulping time is 10-30 minutes, and the deinked pulp after crushing is obtained;

[0033] The high-concentration desanding process is as follows: the crushed deinked pulp enters the high-consistency desander for ...

Embodiment 2

[0083] Embodiment 2, the process method of waste paper deinking of the present invention comprises the following steps: pulping, high-concentration sand removal, coarse screening, low-concentration sand removal, pre-flotation, fine screening, concentration, thermal dispersion, bleaching, post-floating Sorting and pulping process, the waste paper is deinked pulp after going through the above process.

[0084]Among them, the pulping process is carried out according to the following steps, the waste paper and water are placed in the drum pulper, and 0.1-0.8% deinking agent, 0.1-0.8% deinking agent, 0.1-0.8% Sodium silicate, 0.1-0.8% sodium hydroxide and 0.01-0.1% surfactant, the surfactant is anionic surfactant α-alkenyl sulfonate, and the slurry concentration is controlled to be 3-20%. The temperature is 20-70°C, the pulping time is 10-30 minutes, and the deinked pulp after crushing is obtained; high-concentration sand removal, coarse screening, low-concentration sand removal, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com