OLED (organic light-emitting diode) device with all-inorganic auxiliary layer and preparation method thereof

An auxiliary layer and inorganic technology, applied in the field of all-inorganic auxiliary layer OLED devices and their preparation, can solve problems such as cracking, limited industrialization process of organic light-emitting devices, and environmental damage, and achieve improved device stability, rich and delicate colors, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

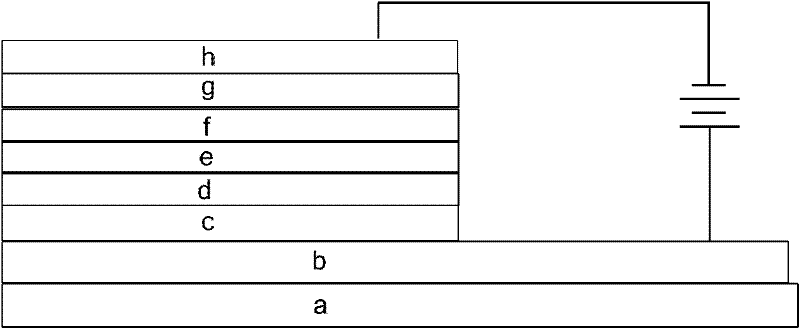

[0050] The flat glass substrate was cleaned with ultrasonic waves in an aqueous solution containing a decontamination agent, rinsed with distilled water and ethanol, and dried. Transfer the substrate to a vacuum thermal evaporation chamber. Sputter aluminum anode 15nm on the glass substrate, respectively sputter on the anode in sequence: molybdenum oxide 15nm; silicon oxide 1nm; molybdenum oxide 25nm; It is 3:1. Then thermally evaporated AlQ 3 75nm; ZnS 8nm; ZnSe 30nm; LiF 1nm; finally thermal sublimation evaporated aluminum 100nm to form the cathode. The deposition rate was kept at 2 angstroms / s for organic materials, 1 angstroms / s for LiF, 5 angstroms / s for aluminum, 2 angstroms / s for silicon oxide, 3 angstroms / s for molybdenum oxide, and finally with Glass cover plate encapsulation, the formed device structure is as follows:

[0051] Glass / Al(15nm) / MoO 3 (15nm) / SiO 2 (1nm) / MoO 3 (25nm) / MoO 3 : SiO 2 3:1 (30nm) / AlQ 3 (75nm) / ZnS(8nm) / ZnSe(30nm) / LiF(1nm) / Al(100nm)....

Embodiment 2

[0064] Sputtering of fluorine-doped tin oxide (SnO 2 : F) The flat glass substrate of the anode is cleaned with ultrasonic waves, then rinsed with distilled water and ethanol and dried. Transfer the substrate to a vacuum thermal evaporation chamber. in SnO 2 : Molybdenum oxide 8nm is sputtered on the F glass substrate, and NPB and molybdenum oxide mixed layer are vapor-deposited 100nm, wherein the molar ratio of NPB and molybdenum oxide is 40:60; AlQ 3 90nm; ZnS 8nm; ZnSe 30nm; LiF 1nm; finally thermal sublimation evaporated aluminum 100nm to form the cathode. The deposition rate was kept at 2 Å / s for organic materials, 1 Å / s for LiF, 5 Å / s for Al, 2 Å / s for ZnS, ZnSe, 3 Å / s for MoO, and finally Encapsulated with a glass cover, the resulting device structure is as follows:

[0065] Glass / SnO 2 :F / MoO 3 (8nm) / NPB:MoO 3 40:60(100nm) / AlQ 3 (90nm) / ZnS(8nm) / ZnSe(30nm) / LiF(1nm) / Al(100nm).

[0066] where SnO 2 : F is a cheap anode, molybdenum oxide is the hole injection l...

Embodiment 3

[0069] The flat glass substrate was cleaned with ultrasonic waves in an aqueous solution containing a decontamination agent, rinsed with distilled water and ethanol, and dried. Transfer the substrate to a vacuum thermal evaporation chamber. Chromium reflective layer 10nm sputtered on glass substrate, aluminum cathode 30nm, LiF 1nm sputtered on cathode; TiO 2 3nm; ZnTe 30nm; then thermal sublimation evaporation TPBi and Ir(ppy) 3 The mixed layer of 80nm, in which TPBi and Ir(ppy) 3 Molar ratio of 100:35; molybdenum oxide 120nm; finally thermal sublimation evaporation aluminum 15nm to form the anode. The deposition rate is maintained at 2 angstroms / sec for organic materials, 5 angstroms / sec for aluminum, and for ZnTe, TiO 2 At 2 angstroms / sec, 3 angstroms / sec for molybdenum oxide, and finally encapsulated with a glass cover plate, the formed device structure is as follows:

[0070] Al(15nm) / MoO 3 (120nm) / TPBi:Ir(ppy) 3 100:35(80nm) / ZnTe(30nm) / TiO 2 (3nm) / LiF(1nm) / Al(30n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com