Epoxy resin bi-component binding agents modified by polyurethane

A technology of polyurethane modification and epoxy resin, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of scarring reject rate, low resin strength, sand washing and sand inclusion, etc., and achieve remarkable casting quality, Improvement of resin strength and improvement of casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

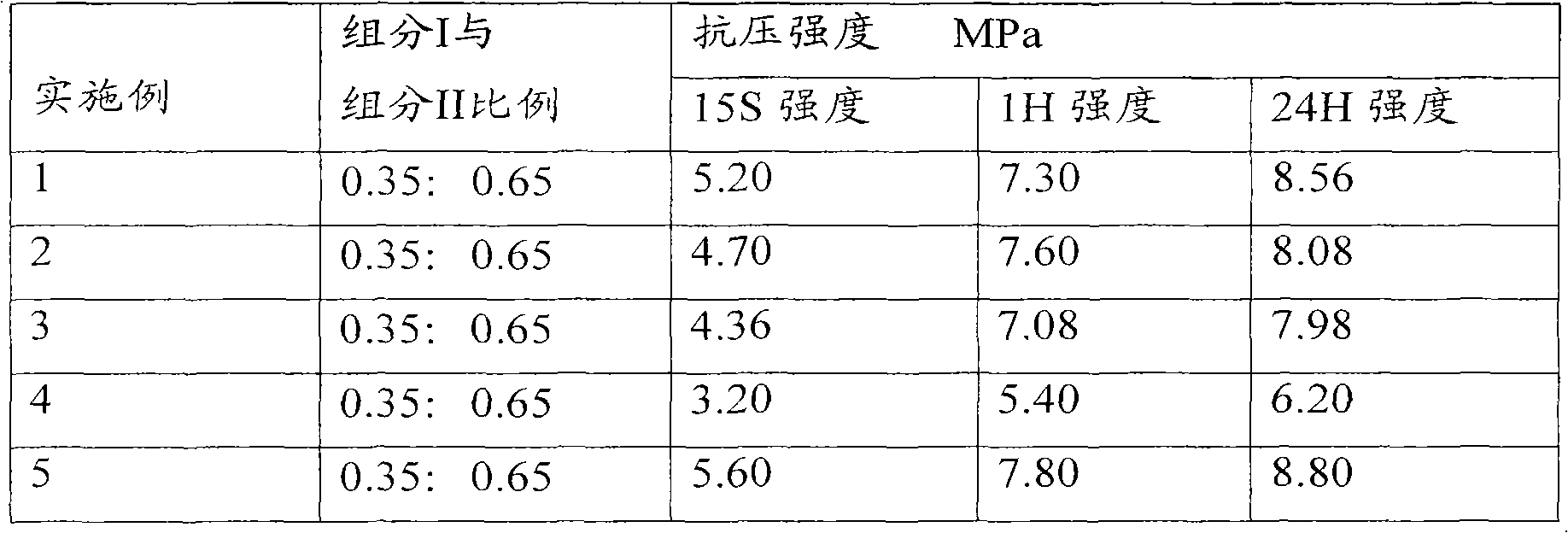

Examples

Embodiment 1

[0044] Preparation of Polyurethane Modified Epoxy Resin

[0045] (1) Put 180 kg of melted benzyl ether phenolic resin into the reaction kettle, heat and stir, and dehydrate under vacuum (vacuum degree is 15 mm Hg), until the temperature reaches 120 °C without bubbles. Cool down to 60°C, add 15 kg of polyisocyanate PM-200;

[0046] (2) Adjust the condenser of the reaction kettle to the reflux state, pass steam under stirring to raise the temperature, raise the temperature to 70°C within 30 minutes, and keep the temperature at 70-90°C for 180 minutes;

[0047] (3) After the heat preservation is over, cool the material to 60°C, add 805 kg of epoxy resin DER 331, raise the temperature in the kettle to 110°C within 60 minutes, and keep the temperature at 110-150°C for 180 minutes, then cool down, That is to obtain polyurethane modified epoxy resin.

[0048] Preparation of Component I: Add 600 kg of the above polyurethane modified epoxy resin, 260 kg of trimethylolpropane triacryl...

Embodiment 2

[0051] Preparation of Polyurethane Modified Epoxy Resin

[0052] (1) Put 160 kg of melted benzyl ether phenolic resin into the reaction kettle, heat and stir, dehydrate under vacuum (vacuum degree is 15mm Hg), until the temperature reaches 120°C and there are no bubbles. Cool down to 60°C, add 20 kg of polyisocyanate PM-200;

[0053] (2) Adjust the condenser of the reaction kettle to the reflux state, pass steam under stirring to raise the temperature, raise the temperature to 70°C within 30 minutes, and keep the temperature at 70-90°C for 180 minutes;

[0054] (3) After the heat preservation is over, cool the material to 60°C, add 820 kg of epoxy resin DER 331, raise the temperature in the kettle to 110°C within 60 minutes, and keep the temperature at 110-150°C for 180 minutes, then cool down, That is to obtain polyurethane modified epoxy resin.

[0055] Preparation of component I: Add 630 kilograms of the above-mentioned polyurethane modified epoxy resin, 200 kilograms of ...

Embodiment 3

[0058] Preparation of Polyurethane Modified Epoxy Resin

[0059] (1) Put 134 kg of melted benzyl ether phenolic resin into the reaction kettle, heat and stir, and dehydrate under vacuum (vacuum degree is 15 mm Hg), until the temperature reaches 120 ° C without bubbles. Cool down to 60°C, add 16 kg of polyisocyanate PM-200;

[0060] (2) Adjust the condenser of the reaction kettle to the reflux state, pass steam under stirring to raise the temperature, raise the temperature to 70°C within 30 minutes, and keep the temperature at 70-90°C for 180 minutes;

[0061] (3) After the heat preservation is over, cool the material to 60°C, add 850 kg of epoxy resin DER 331, raise the temperature in the kettle to 110°C within 60 minutes, and keep the temperature at 110-150°C for 180 minutes, then cool down, That is to obtain polyurethane modified epoxy resin.

[0062] The preparation of component I: 610 kilograms of above-mentioned polyurethane modified epoxy resins, 220 kilograms of trime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com