System and method for releasing micro-electromechanical system (MEMS) structure by etching silicon sacrificial layer

A sacrificial layer and assisted etching technology, which is applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, can solve problems such as reducing efficiency, increasing operating costs, affecting etching rate and throughput, and achieving high productivity High, good uniformity, fast etching rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

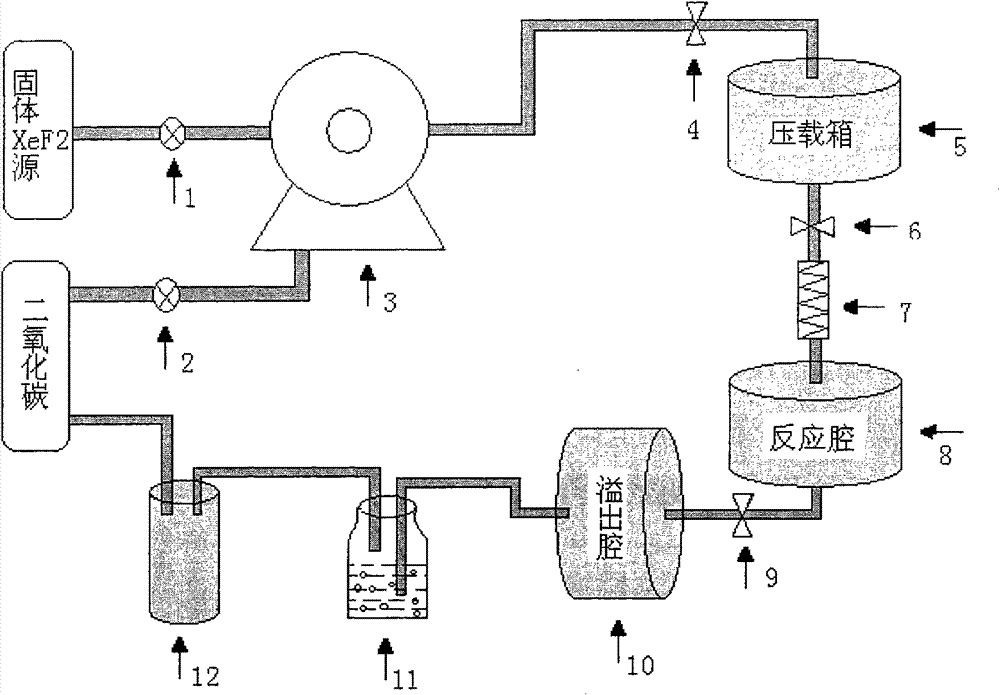

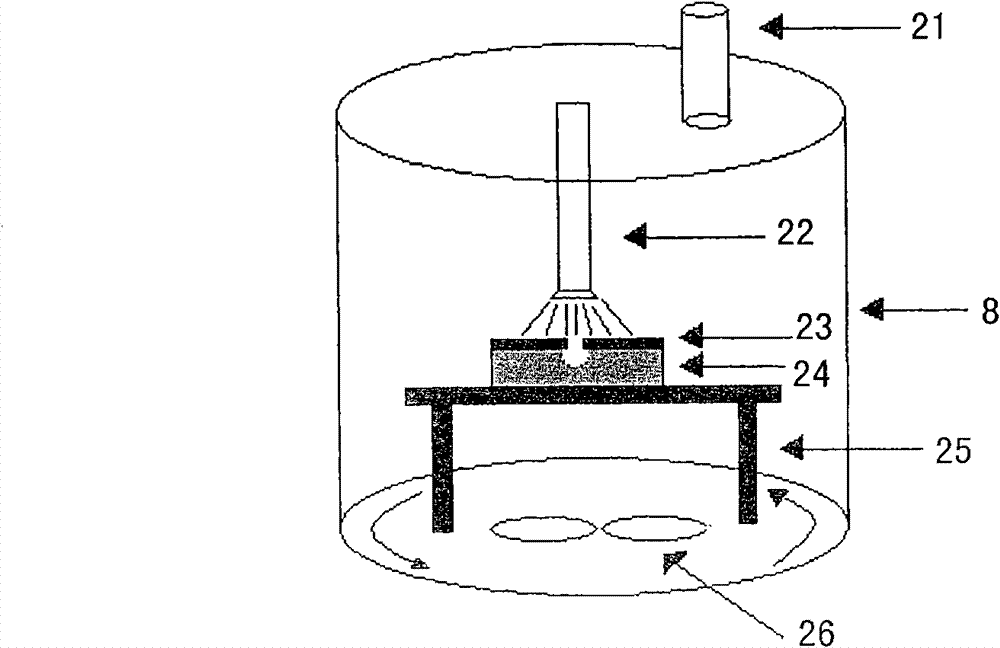

[0041] The invention provides a method for releasing a MEMS structure by etching a silicon sacrificial layer. The method uses xenon difluoride as an etching reaction gas, and supercritical carbon dioxide as a carrier gas to release the silicon sacrificial layer. Carbon dioxide makes use of its supercritical state properties to make the etching of silicon by xenon difluoride more uniform, the smoothness of the corroded surface is higher, and the etching is more complete. Compared with traditional wet release and plasma release, this release method avoids damage to the device due to stirring or adhesion in wet release, can improve the uniformity of the entire wafer, and has a faster reaction rate, high efficiency, and time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com