Metal foil winding type vacuum coating equipment

A vacuum coating and metal foil strip technology, which is applied in vacuum evaporation coating, metal material coating process, sputter coating, etc., can solve the problem of correcting coating process parameters, poor firmness and reliability of the entire roll of foil strip, and process Unreliable and other problems, achieve uniform etching, ensure color uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be further described in detail below in conjunction with the accompanying drawings.

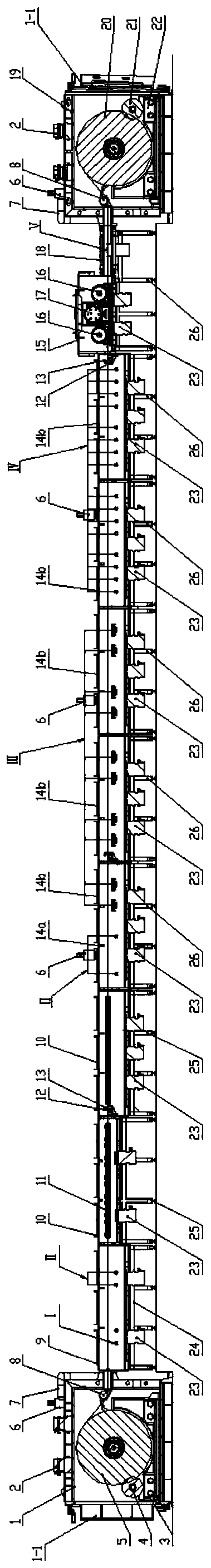

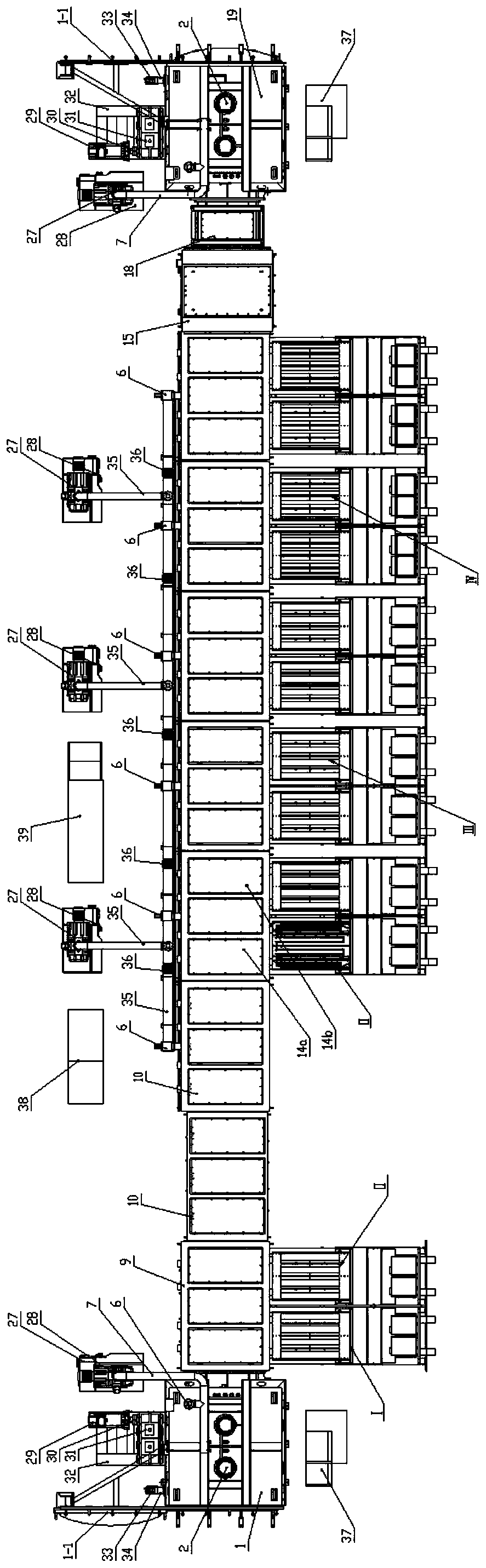

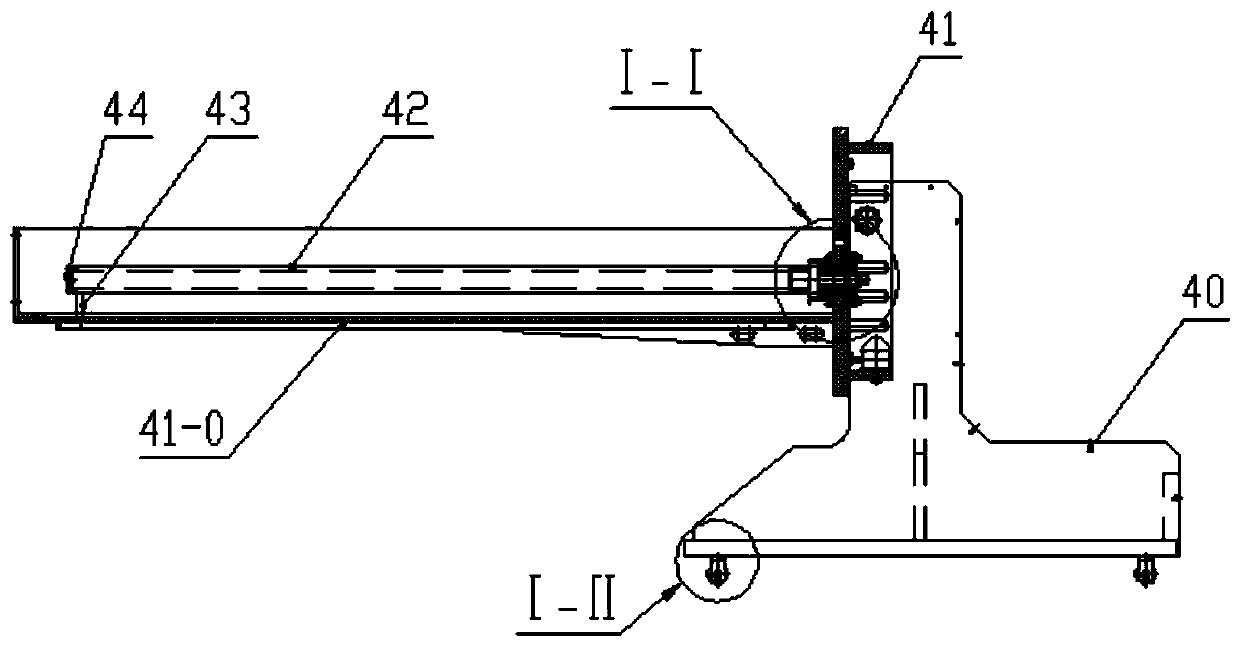

[0089] figure 1 It is a schematic diagram of the main view of the continuous coating production line of ion plating on metal foil strip winding, figure 2 for figure 1 top view diagram.

[0090] The two pictures show the layout structure of the entire production line. The production line is divided into eight cabins connected by vacuum successively. The first cabin is the unwinding cabin 1, the second is the vacuum ion removal cabin 9, and the third is the heating cabin 10. , the fourth is the arc electron source ion bombardment etching chamber 14a, the fifth is the coating chamber 14b, the sixth is the cooling and foil tension adjustment chamber 15, the seventh is the online color detection chamber 18, the eighth For the winding cabin 19.

[0091] There are movable doors at the front and rear of each compartment of the production line for the entry and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com