10B zirconium diboride and preparation method thereof

A technology of zirconium diboride and zirconium dioxide, which is applied in the field of 10B zirconium diboride and its preparation, can solve the problems of impossible preparation of zirconium diboride products, achieve good crystallinity, avoid operation losses and be easy to remove. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

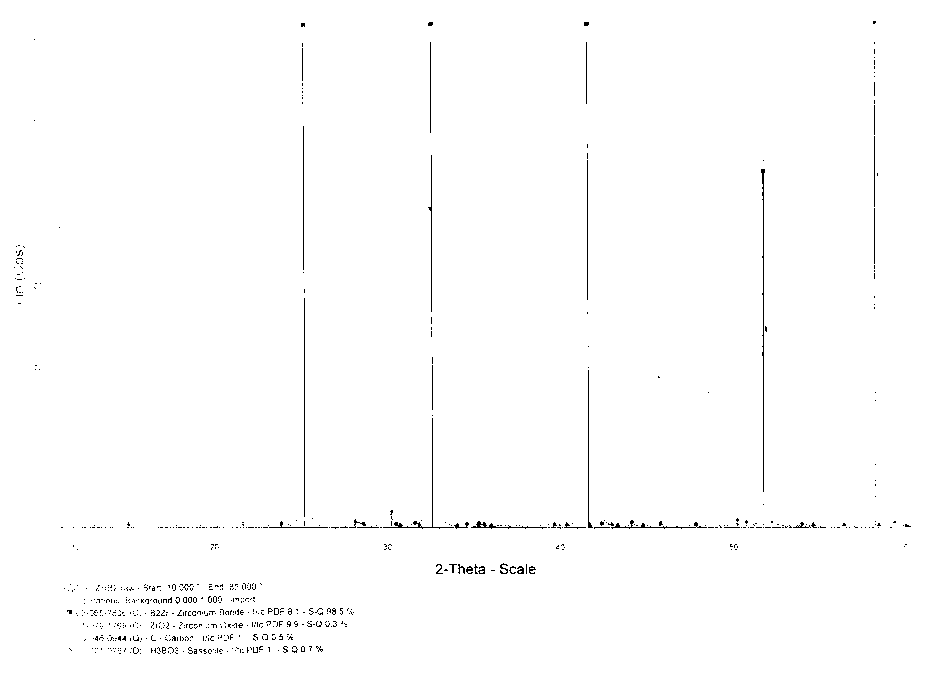

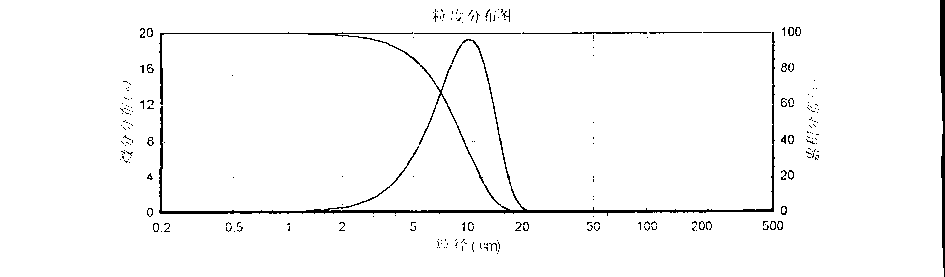

Image

Examples

Embodiment 1

[0027] preparation 10 The abundance of B is 25% (at.) zirconium diboride, the raw material used is zirconium dioxide, the purity is 99.9wt%, and the particle size is d 50 10 B boron carbide, 10 B abundance 25wt% (at.), boron carbide content 95wt%, particle size d 50 50 <4μm, for commercial products;

[0028] The preparation steps are as follows:

[0029] (1) by mass parts, 72 parts of zirconium dioxide, 10 B 22 parts of boron carbide with an abundance of 25% (at.) and 6 parts of graphite powder are mixed to form a mixed material, which is then loaded into a dispersing sand mill, and absolute ethanol with 5 times the mass of the mixed material is added as a dispersant , using zirconia balls, milling for 2 hours, to obtain ethanol mixed powder;

[0030] (2) Place the ethanol mixed powder in a drying oven, and dry at 100°C for 60 minutes until all the ethanol evaporates to obtain a dried mixed powder;

[0031] (3) Add the dry mixed powder into the graphite crucible of...

Embodiment 2

[0035] preparation 10The abundance of B is 65% (at.) zirconium diboride, the raw material used is dehafnium dioxide, the purity is 99.9wt%, and the particle size is d 50 10 B boron carbide, 10 B abundance 65% (at.), boron carbide content 95.6wt%, particle size d 50 50 <4μm, for commercial products;

[0036] The preparation steps are as follows:

[0037] (1) In parts by mass, 75 parts of dehafnium dioxide, 10 B 20 parts of boron carbide with an abundance of 65% (at.) and 5 parts of graphite powder are mixed to form a mixed material, which is then loaded into a dispersing sand mill, and absolute ethanol with 7 times the mass of the mixed material is added as a dispersant , using zirconia balls for 5 hours of ball milling time to obtain ethanol mixed powder;

[0038] (2) Place the ethanol mixed powder in a drying oven, and dry at 100°C for 60 minutes until all the ethanol evaporates to obtain a dried mixed powder;

[0039] (3) Add the dry mixed powder into the graphit...

Embodiment 3

[0042] preparation 10 The abundance of B is 99% (at.) zirconium diboride, the raw material used is zirconium dioxide, the purity is 99.9wt%, and the particle size is d 50 10 B boron carbide, 10 B abundance 99% (at.), boron carbide content 95.6wt%, particle size d 50 50 <4μm, for commercial products;

[0043] The preparation steps are as follows:

[0044] (1) by mass parts, 70 parts of zirconium dioxide, 10 B 21 parts of boron carbide with an abundance of 99% (at.) and 9 parts of graphite powder are mixed to form a mixed material, which is then loaded into a dispersing sand mill, and absolute ethanol with 10 times the mass of the mixed material is added as a dispersant , using zirconia balls, milling for 3 hours, to obtain ethanol mixed powder;

[0045] (2) Place the ethanol mixed powder in a drying oven, and dry at 100°C for 60 minutes until all the ethanol evaporates to obtain a dried mixed powder;

[0046] (3) Add the dry mixed powder into the graphite crucible o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com