Cladded pumping optical fiber capable of efficiently adsorbing pumping light

A high-efficiency technology for pumping optical fibers, applied in the direction of cladding optical fibers, graded index core/clad optical fibers, multi-layer core/clad optical fibers, etc., can solve low flexibility, difficult pump absorption, Problems such as high splicing loss of optical fiber, to achieve good flexibility, simplify the process flow, and reduce the effect of splicing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

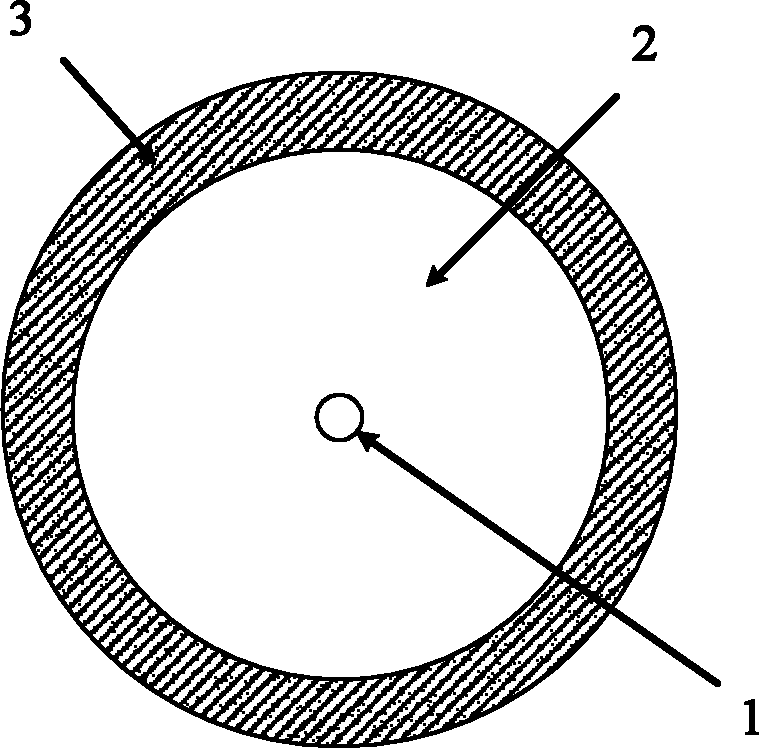

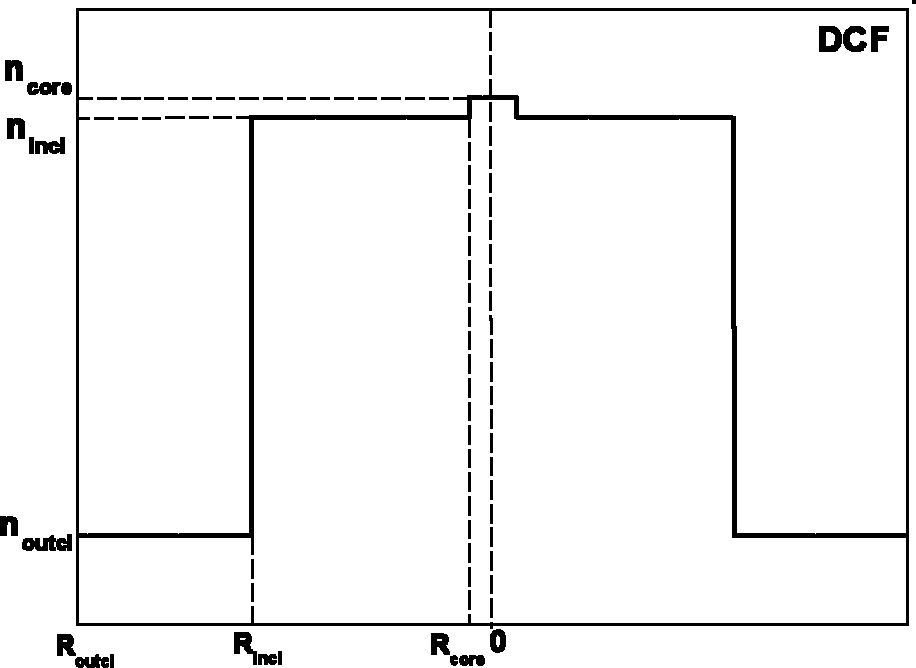

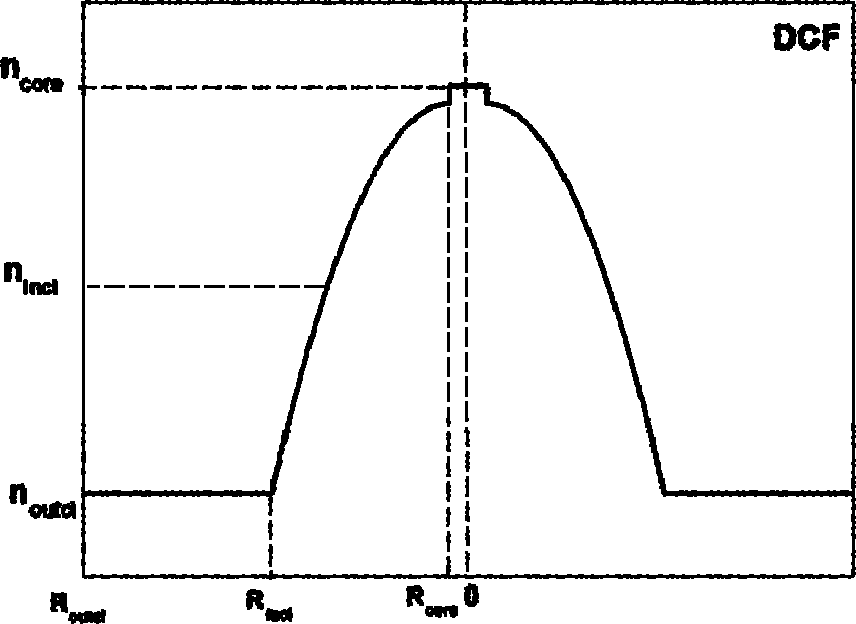

[0031] The double-clad rare-earth-doped optical fiber of the present invention includes three parts: core 1, inner cladding 2 and outer cladding 3, the refractive index of the core region is uniformly distributed, and its refractive index is the largest, and the refractive index of the outer cladding is also uniformly distributed , its refractive index is the smallest, and the inner cladding is composed of 10 layers of quartz structures whose refractive index changes from high to low, such as Figure 5 As shown, the gradual change of the inner cladding refractive index is realized through the multi-layer structure, the inner cladding refractive index gradually decreases from the core to the outer cladding direction, the core refractive index is greater than the maximum refractive index of the inner cladding, and the outer cladding refractive index is smaller than the inner cladding minimum refractive index.

Embodiment 2

[0033] Such as Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the inner cladding is composed of 20 layers of quartz whose refractive index varies from high to low.

Embodiment 3

[0035] Such as Figure 7As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the inner cladding is composed of 30 layers of quartz whose refractive index varies from high to low.

[0036] The more layers of the stepped inner cladding structure, the closer the refractive index distribution of the inner cladding is to continuous, but the manufacturing difficulty will also increase relatively.

[0037] Figure 4 It is a comparison chart of the pump absorption coefficient of step type and graded double clad fiber. The data is calculated through a strict mathematical model. The same size of incident pump beam, doped core radius, and core absorption coefficient are used in the calculation. and inner cladding area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com