Method for reducing operation power consumption of phase change memory unit

A phase-change memory, cell operation technology, applied in static memory, digital memory information, information storage, etc., to achieve the effect of reducing operating voltage and operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

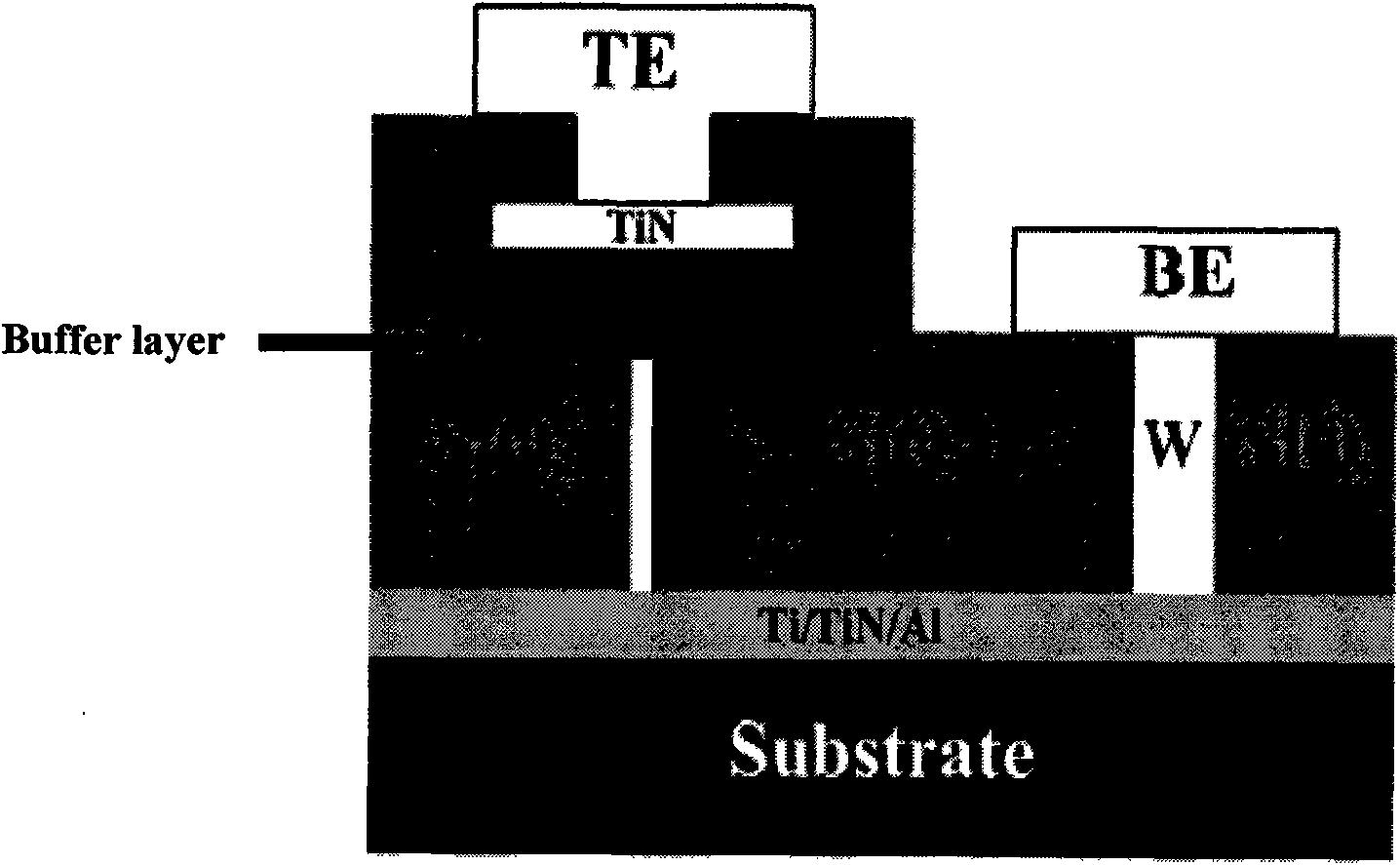

[0022] Adoption of BaTiO in Phase Change Memory Devices 3 as a buffer layer.

[0023] a. SiO after photolithography treatment by magnetron sputtering 2 / Si substrate prepared BaTiO with a thickness of 10nm 3 Thin film, the sputtering power is 20W, oxygen and argon gas are passed through during sputtering, and the ratio of oxygen partial pressure to argon partial pressure is 1:3.

[0024] b. The prepared BaTiO 3 The film was annealed in an oxygen atmosphere for 10 minutes at a temperature of 400° C. to obtain the final buffer layer material.

[0025] c. SiO coated with buffer layer material 2 GST phase-change material with a thickness of 150nm was prepared by magnetron sputtering on the / Si substrate, and packaged into a phase-change memory device.

Embodiment 2

[0027] The use of SrTiO in phase change memory devices 3 as a buffer layer.

[0028] a. SiO after photolithography treatment by magnetron sputtering 2SrTiO with a thickness of 10nm was prepared on a Si substrate 3 Thin film, the sputtering power is 20W, oxygen and argon gas are passed through during sputtering, and the ratio of oxygen partial pressure to argon partial pressure is 1:3.

[0029] b. The prepared SrTiO 3 The film was annealed in an oxygen atmosphere for 10 minutes at a temperature of 400° C. to obtain the final buffer layer material.

[0030] c. SiO coated with buffer layer material 2 GST phase-change material with a thickness of 150nm was prepared by magnetron sputtering on the / Si substrate, and packaged into a phase-change memory device.

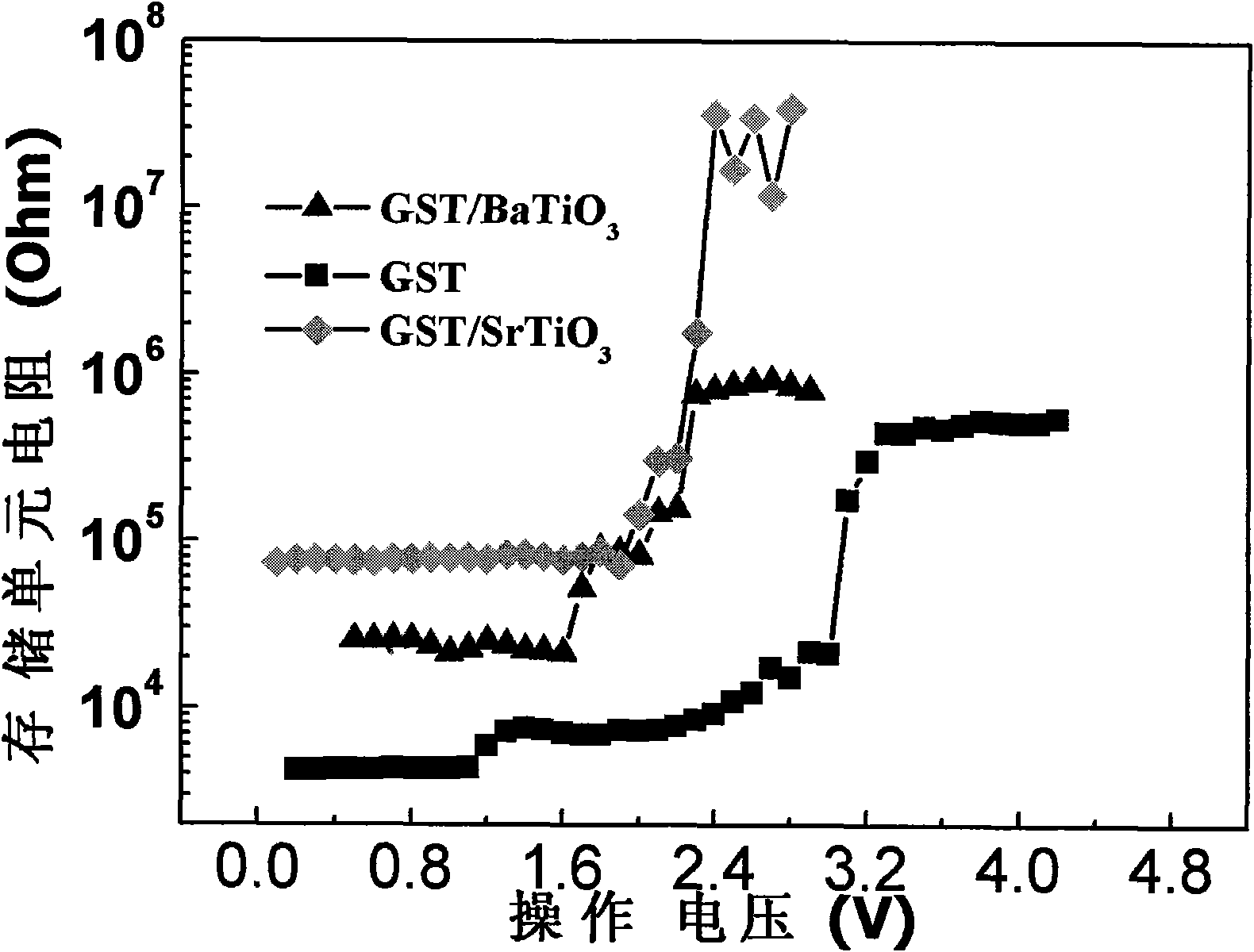

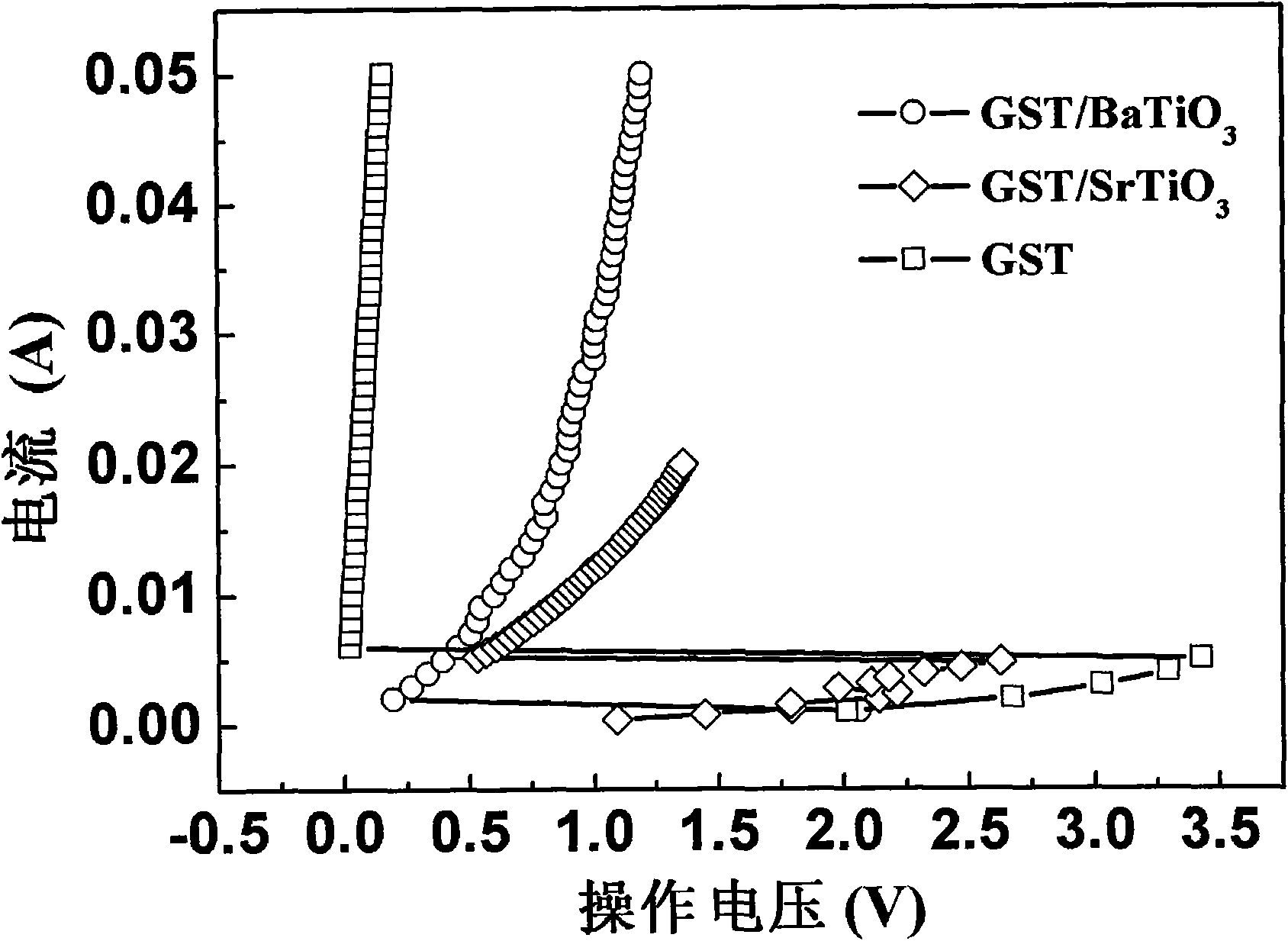

[0031] The test of the resistance-voltage and current-voltage performance during the reset process of the phase change memory device is to use the Agilent-81104A pulse signal generator to output a specific voltage pulse,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com