Composite material stripline waveguide array antenna

A technology of composite materials and waveguide arrays, which is applied to antenna arrays, antennas, antenna supports/mounting devices, etc., can solve the problems of relatively stringent weight requirements for microwave antennas, reduce material costs, overcome complex structures, and have good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

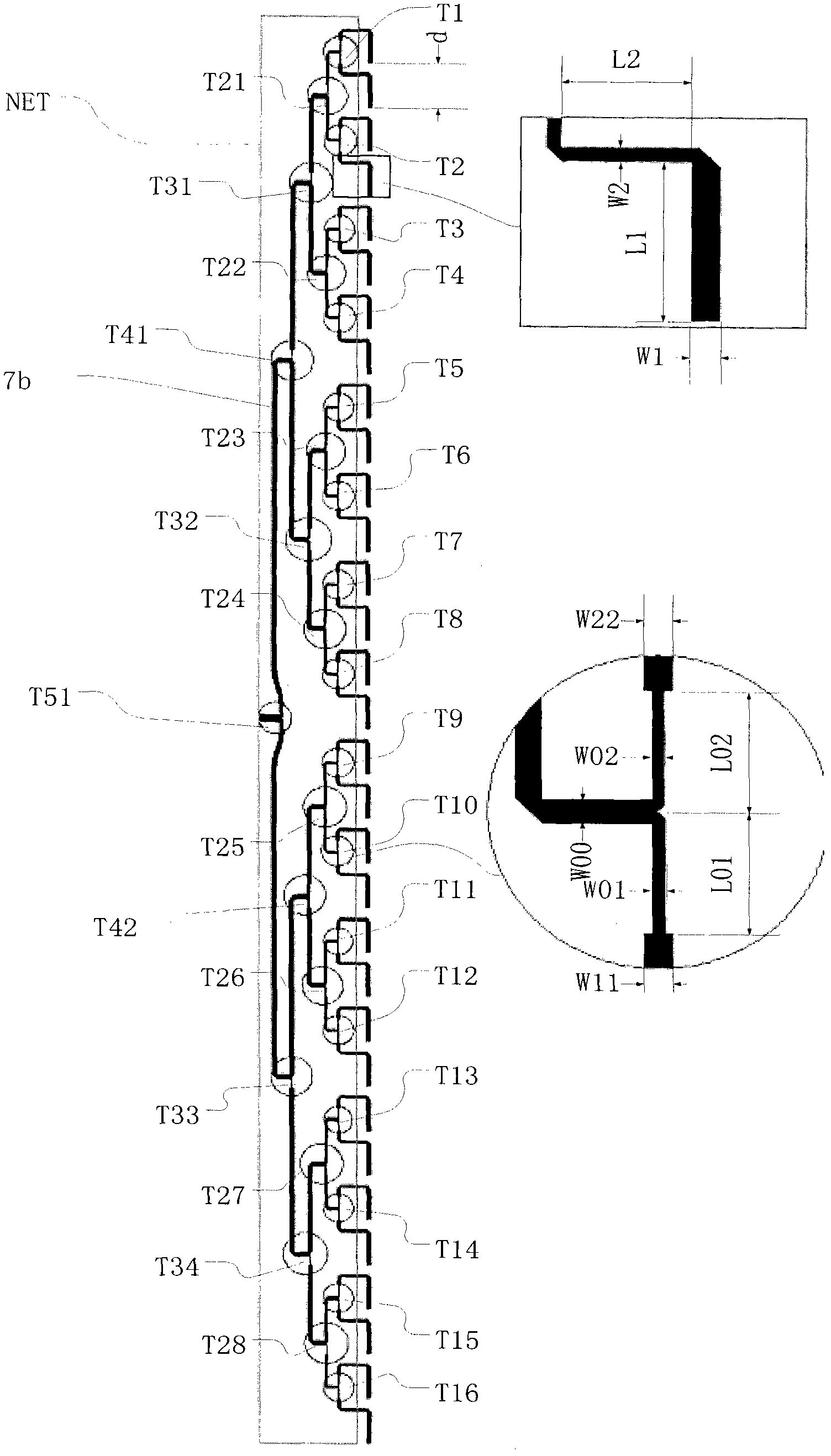

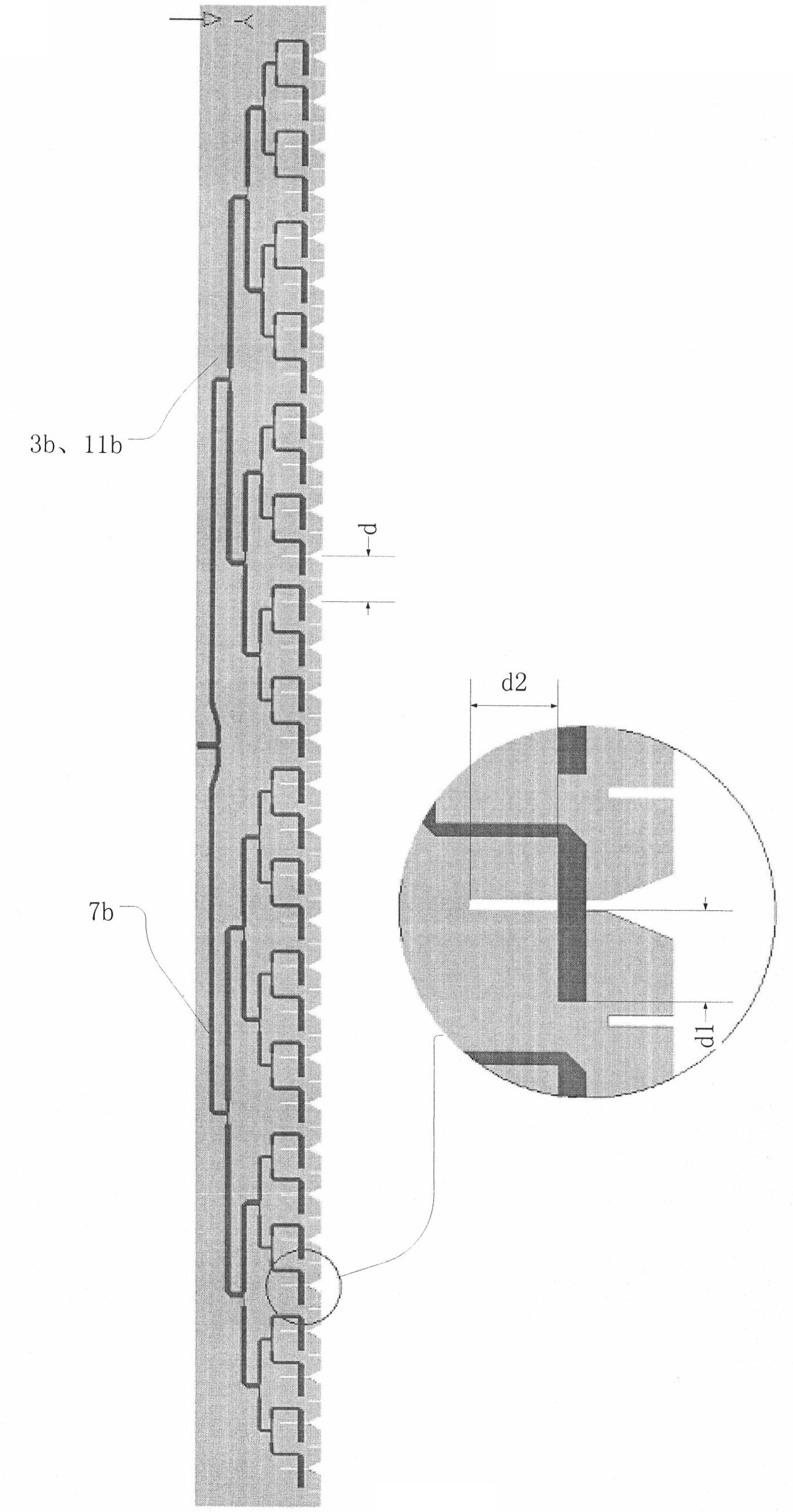

[0014] The design frequency band of the present invention is S-band 3.1GHz-3.4GHz, the number of array units is 32, and the unit spacing d=72mm Combined with the above-mentioned drawings, the present invention will be further described through the embodiments.

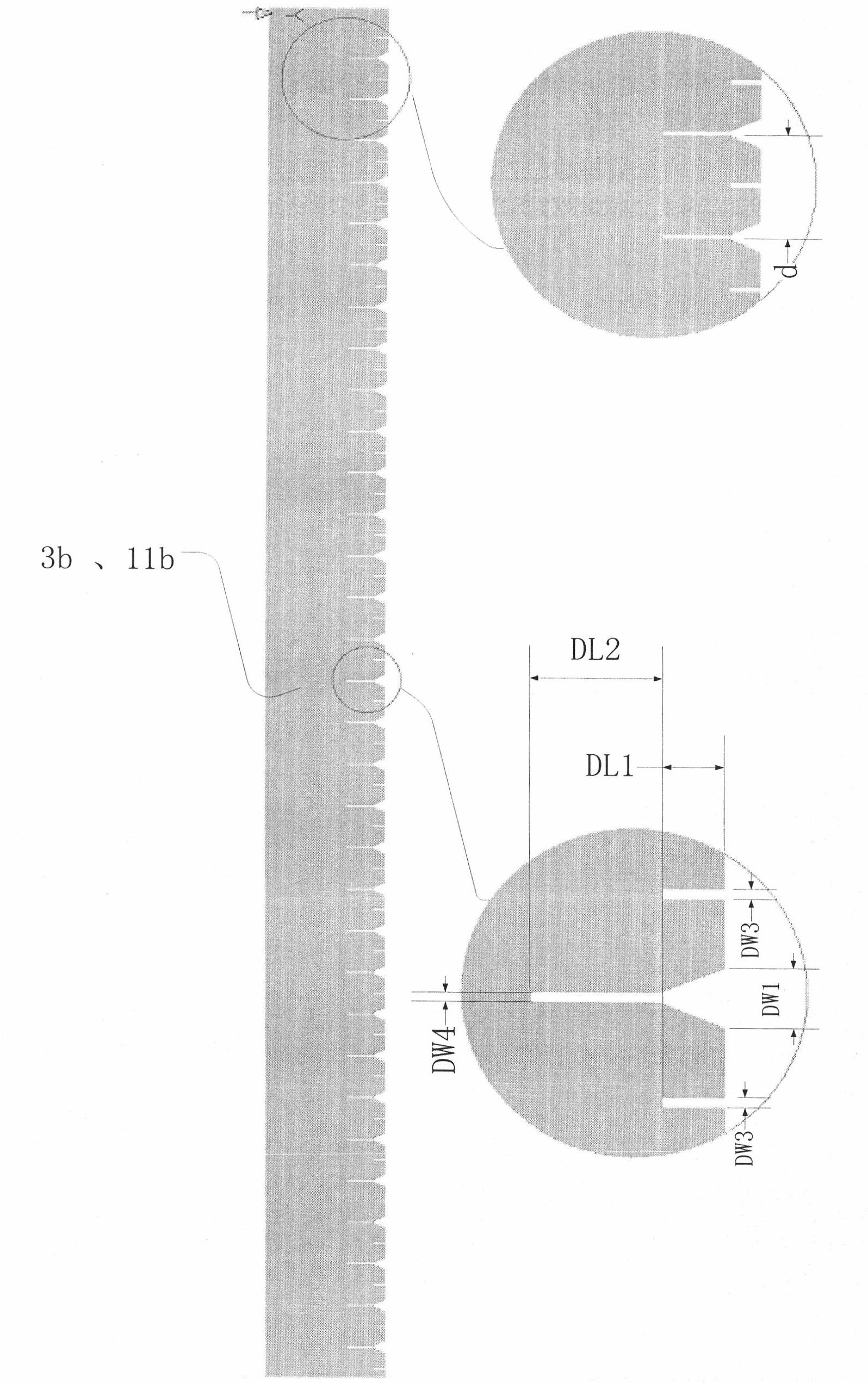

[0015] Such as figure 2 As shown, two LPI halogen-free polyimide film single-sided copper-clad laminates 3 and 11 are used, one positive and one reverse are used as the outer conductor of the composite strip line array antenna, and one positive and one reverse are printed simultaneously. Radiating slot horns and isolation slots with equal spacing d such as figure 2 3b and 11b shown are used as the radiating slot horn array of the array antenna. Such as figure 1 As shown, another single-sided copper-clad laminate of LPI halogen-free polyimide film is used as the center conductor of the composite strip line array antenna, and the inner conductor and the strip line power division of 32 are printed on it. The feeder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com