Debitterized honey pomelo granule beverage and making method thereof

A production method and honey pomelo technology are applied in the direction of food science, etc., which can solve the problems of poor product molding state and taste, easy boiled honey pomelo meat, and insufficient degree of bitterness removal of honey pomelo particles, so as to shorten the debittering time, Chewing taste is good, the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

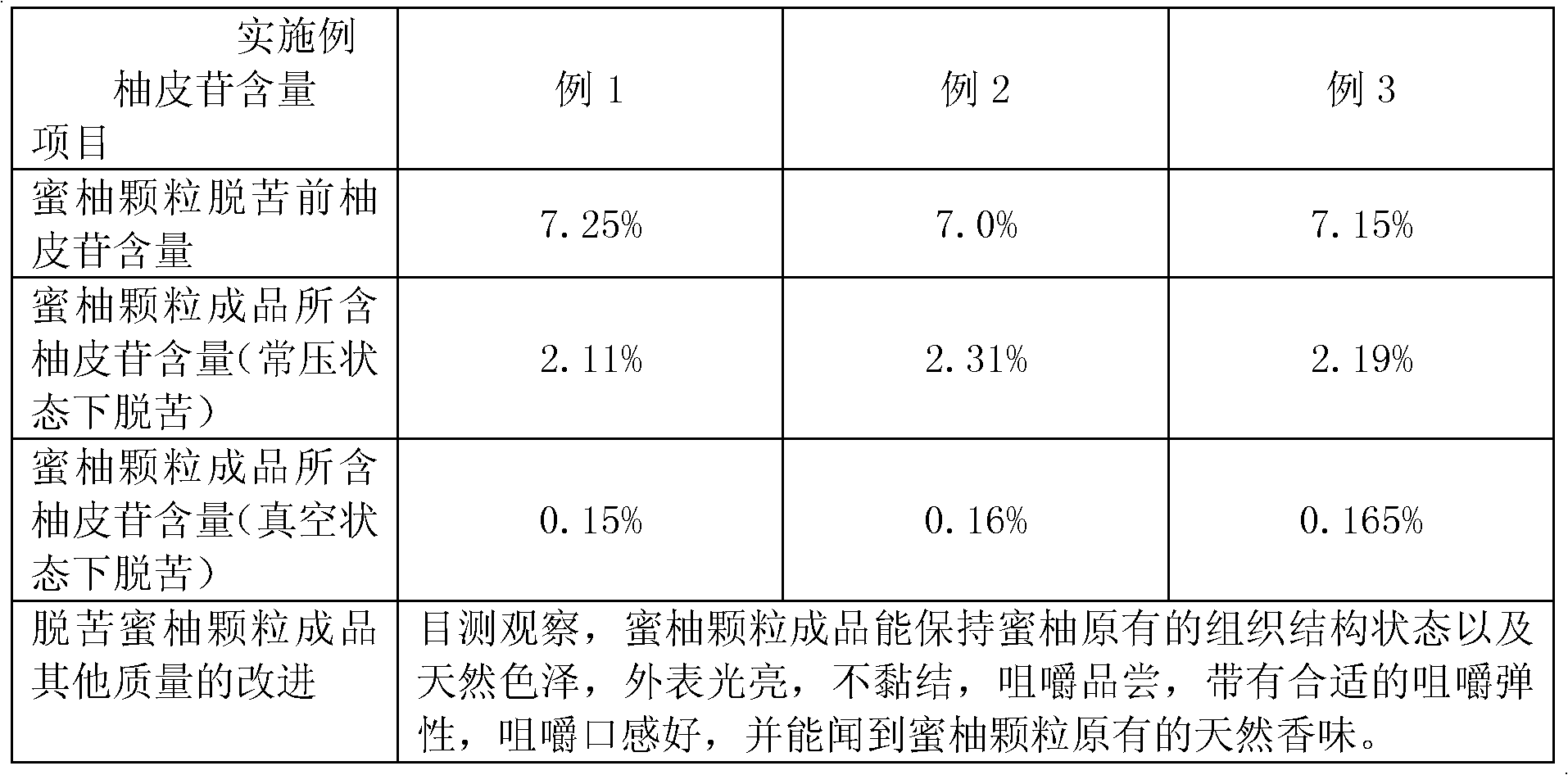

Embodiment 1

[0031] (1) Pretreatment of pomelo fresh fruit: the pomelo fresh fruit is automatically cleaned in 25-35°C room temperature water for 2-3 minutes for clean water and cleaning. Sterilize in a chlorine dioxide solution with a concentration of 100ppm for 30 seconds at room temperature, then blow dry, cut the honey pomelo into pieces, and separate the honey pomelo peel from the honey pomelo pulp.

[0032] (2) Add the pomelo pulp into the water of the separator and separate it into particles.

[0033] (3) Under vacuum conditions, the bittering element in the granules is removed by debittering liquid reverse osmosis, and the debittered honey pomelo granules are separated from the debittering liquid. Wherein honey pomelo granule, the process condition of vacuum debittering are: debittering solution is divided into by weight percentage proportioning ratio:

[0034] Sodium chloride 3% β-cyclodextrin 0.2% Vacuum degree 0.08mpa The balance is water Temperature 60°C

[0035] Put the debi...

Embodiment 2

[0041] Its processing steps (1) (2) (3) (5) (6) (7) are the same as in Example 1, and the other steps are that the processing conditions are separation from the debittering solution. Wherein the technological condition of vacuum debittering of pomelo granule is: debittering solution is divided into by weight percentage ratio:

[0042] Sodium chloride 4% β-cyclodextrin 0.2% Vacuum degree 0.08mpa The balance is water Temperature 70°C

[0043] Put the debittering liquid and pomelo granules of the above formula into a vacuum tank, the weight ratio of the pomelo granules to the debittering liquid is 100:25, and debitterize for 80 minutes at a temperature of 70° C. and the above-mentioned vacuum conditions.

[0044] The proportioning liquid is as follows according to weight percentage: 9% of white granulated sugar, 0.40% of citric acid, 20% of debittered pomelo granules, 15% of debittered pomelo juice, 0.15% of stabilizer cmc, and the balance is water. Wherein the purity of white g...

Embodiment 3

[0046] Its processing step (1) (2) (3) (5) (6) (7) is identical with embodiment 1, and the processing condition of other steps is:

[0047] The debittering liquid is used to remove the bittern in the pomelo granules under vacuum condition, and the debittering pomelo granules are separated from the debittering liquid. Wherein the technological condition of honey pomelo particle vacuum debittering is:

[0048] Sodium chloride 5%, β-cyclodextrin 0.3%, vacuum degree 0.08mpa, balance is water, temperature 80℃

[0049] Put the debittering liquid and honey pomelo granules of the above formula into an empty tank, the weight ratio of the honey pomelo granules to the debittering liquid is 100:27%, and debitterize for 80 minutes at a temperature of 80° C. and the above-mentioned vacuum degree.

[0050] The proportioning liquid is as follows according to weight percentage: 10% of white granulated sugar, 0.50% of citric acid, 12% of debittered pomelo granules, 12% of debittered pomelo jui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com