Preparation method for composite film of chitosan/sulfonated polyethersulfone and polyethersulfone and application thereof

A technology of sulfonated polyethersulfone and polyethersulfone, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good dehydration performance, abundant raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

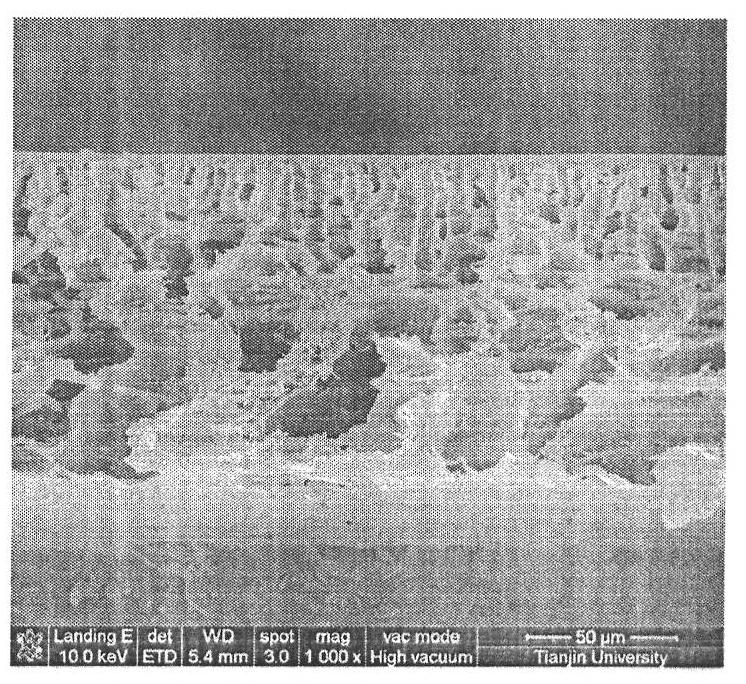

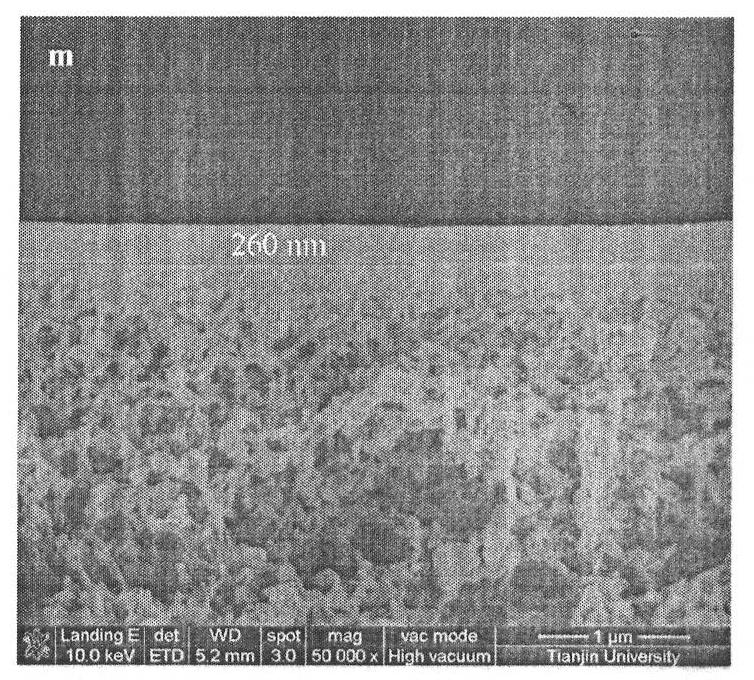

Image

Examples

Embodiment 1

[0011] Weigh 2.5g of chitosan with a deacylation degree of 90.2%, put 2.5g of glacial acetic acid and 95g of aqueous solution into a three-necked flask, heat in a constant temperature water bath at 80°C, and stir at a speed of 500r / min for 1h. After the chitosan is completely dissolved, the temperature is lowered to 25° C., filtered through a copper mesh, and allowed to stand for 1 hour for defoaming to prepare a chitosan-acetic acid solution with a mass concentration of 2.5%. Weigh 10g of polyethersulfone, measure 100mL of chloroform solution into a three-necked flask, put the three-necked flask into an ice-water bath after it is completely dissolved, add 50mL of chloroform solution containing 6g of chlorosulfonic acid drop by drop with a dropping funnel, at 500r / / Min speed stirring for 1.5h, the prepared solution was poured into a large amount of deionized water and washed several times until the solution became neutral, and dried to obtain sulfonated polyethersulfone. Weigh...

Embodiment 2

[0013] Weigh 2.5g of chitosan with a deacylation degree of 90.2%, put 2.5g of glacial acetic acid and 95g of aqueous solution into a three-necked flask, heat in a constant temperature water bath at 80°C, and stir at a speed of 500r / min for 1h. After the chitosan is completely dissolved, it is lowered to 25° C., filtered, and allowed to stand for 1 hour for defoaming to prepare a chitosan-acetic acid solution with a mass concentration of 2.5%. Weigh 10g of polyethersulfone, measure 100mL of chloroform solution into a three-necked flask, put the three-necked flask into an ice-water bath after it is completely dissolved, add 50mL of chloroform solution containing 6g of chlorosulfonic acid drop by drop with a dropping funnel, at 500r / / Stir at a speed of min for 3 hours, pour the solution into a large amount of deionized water and wash it several times until the solution becomes neutral, and dry to obtain sulfonated polyethersulfone. Weigh 1.2g of sulfonated polyethersulfone, 1.8g ...

Embodiment 3

[0015] Weigh 2.5g of chitosan with a deacylation degree of 90.2%, put 2.5g of glacial acetic acid and 95g of aqueous solution into a three-necked flask, heat in a constant temperature water bath at 80°C, and stir at a speed of 500r / min for 1h. After the chitosan is completely dissolved, it is lowered to 25° C., filtered, and allowed to stand for 1 hour for defoaming to prepare a chitosan-acetic acid solution with a mass concentration of 2.5%. Weigh 10g of polyethersulfone, measure 100mL of chloroform solution into a three-necked flask, put the three-necked flask into an ice-water bath after it is completely dissolved, and add 50mL of chloroform solution containing 6g of chlorosulfonic acid drop by drop with a dropping funnel, at 500r / / Stir at a speed of min for 4.5 hours, pour the solution into a large amount of deionized water and wash it several times until the solution becomes neutral, and dry to obtain sulfonated polyethersulfone. Weigh 1.2g of sulfonated polyethersulfone,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com