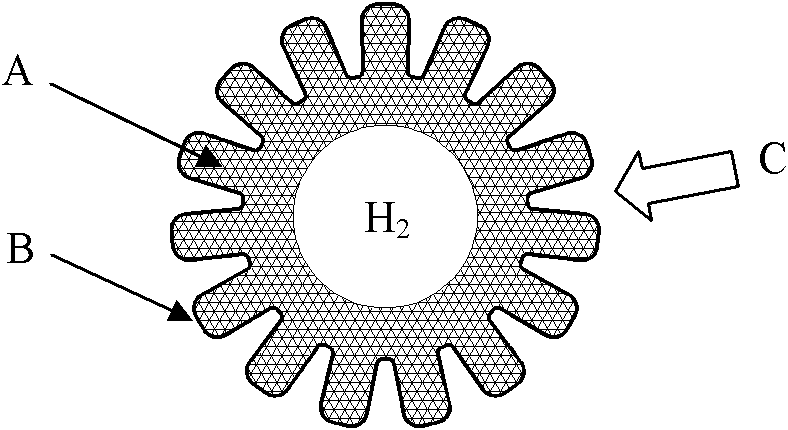

Gear type hydrogen-permeable palladium or palladium alloy film and hydrogen separator

A palladium alloy membrane, gear-type technology, applied in the field of high-efficiency hydrogen permeable membrane, can solve the problems of high preparation difficulty, poor mechanical strength, expensive base material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The gear-shaped palladium membrane is prepared by electroless plating, and the membrane area of the membrane is increased by 120% compared with the tubular membrane with the same outer diameter and length.

[0025] (1). The outer diameter of the gear-type porous ceramic substrate is 30 mm, the inner diameter is 15 mm, the number of teeth is 15, the height of the teeth is 5 mm, the length of the gear is 200 mm, and the length of the round tubes at both ends is 25 mm. After cleaning the substrate with commercially available dish soap, rinse with water.

[0026] (2). Using conventional SnCl 2 / PdCl 2 The activation method activates the surface of the gear-type substrate, wherein the sensitizing solution contains SnCl 2 5g / L, hydrochloric acid 1ml / L; activation solution contains PdCl 2 0.2g / L, hydrochloric acid 1ml / L. Plug the inner tube of the matrix with a silica gel plug, first dip it in the sensitizing solution and rinse it with water, then dip it in the activat...

Embodiment 2

[0031] The gear-shaped palladium-silver alloy membrane is prepared by electroless plating, and the membrane area of the membrane is increased by 130% compared with the tubular membrane with the same outer diameter and length.

[0032] (1). Same as the steps (1), (2), (3), (4), (5) of Example 1, but select the gear-type porous ceramic substrate with an outer diameter of 20 mm, an inner diameter of 10 mm, a number of teeth of 15, and a tooth height 3mm, the length of the gear is 200mm, and the length of the round tube at both ends is 25mm; step (2) is changed to Pd(OH) 2 For the activation method, refer to the Chinese patent (an activation process of electroless plating on non-metallic substrates. ZL200710022996.6); step (4) is changed to a theoretically calculated palladium film thickness of 4 μm, and the electroless plating is stopped.

[0033] (2). Electroless silver plating on the surface of palladium film. The composition of the silver plating solution is: AgNO 3 5g / L,...

Embodiment 3

[0037] The gear-type palladium-copper alloy membrane is prepared by electroless plating and electroplating, and the membrane area of the membrane is increased by 270% compared with the tubular membrane with the same outer diameter and length.

[0038] (1). Steps (1), (2), (3), (4), and (5) of Example 1, but select the gear type porous ceramic substrate with an outer diameter of 50 mm, an inner diameter of 25 mm, a number of teeth of 30, and a tooth height 8mm, gear length 200mm, and circular tube lengths at both ends of 30mm; step (4) was changed to a theoretically calculated palladium film thickness of 3 μm, and the electroless plating was stopped.

[0039] (2). Electroplating is used to plate copper on the surface of the palladium film, and the composition of the copper electroplating solution is CuSO 4 ·5H 2 O 150-200g / L, sulfuric acid 50-70g / L, chloride ion 20-80mg / L, polyethylene glycol 0.05-0.1g / L, ethylene thiourea 0.2-0.7mg / L. The current density is 2A / dm 2 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com