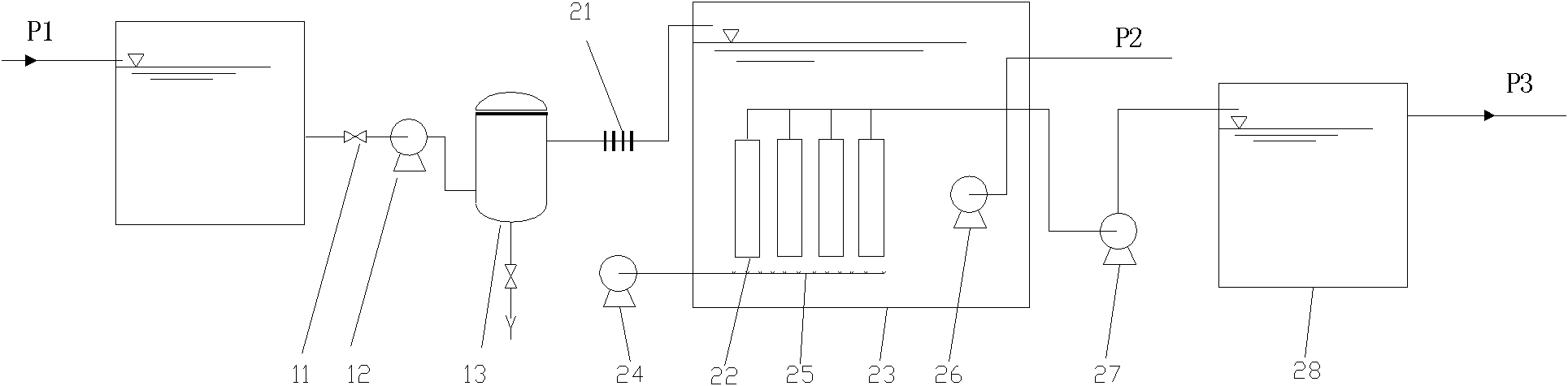

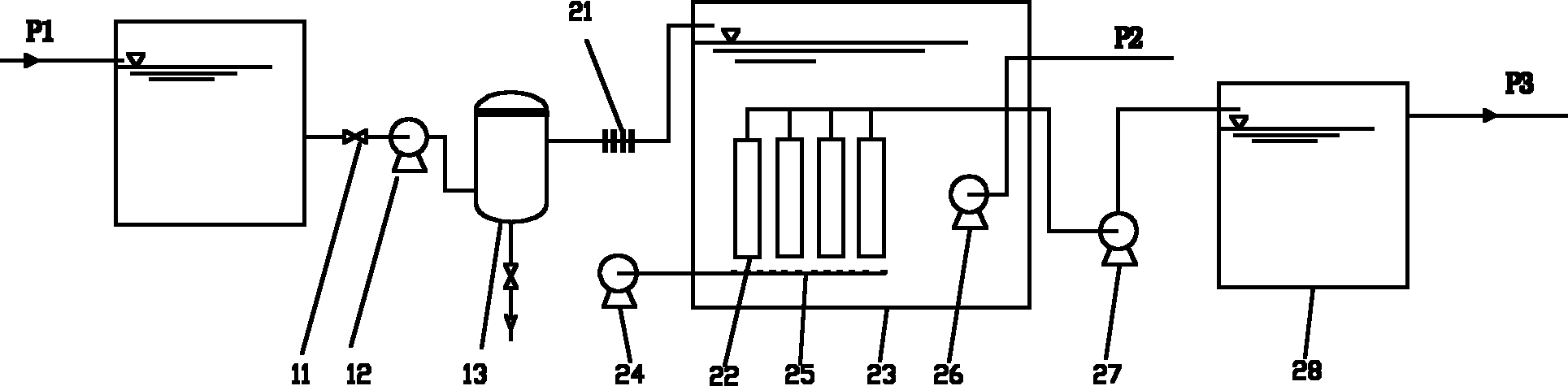

Sewage recycling device based on electrolysis and membrane biological reactor technology and method thereof

A technology of sewage circulation and technology, applied in the direction of chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult to meet the water quality requirements of production process water, poor quality of regenerated water, high operating costs, etc., to achieve Save material consumption, high recovery rate, good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: 500 tons / day advanced treatment sewage purification and recycling project.

[0050] The measured indicators of the sewage are shown in Table 1.

[0051] Table 1

[0052] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

56

5

19

2

BOD 5

mg / L

7

6

Chroma

60

3

SS

mg / L

13

7

pH

7.3

4

NH 3 -N

mg / L

23

8

μS / cm

410

[0053] Step 1, electrolysis: start the water supply pump 12, and the sewage 3 The / h flow rate enters the electrolysis machine 13 through the stop valve 11 for electrolysis. The working voltage of the electrolysis is 12V, the voltage between the two electrodes is 3.5-8.2V, and the current density is 130mA / cm 2 , Under the action of current, the nascent chlorine [Cl], hydroxyl [OH] ...

Embodiment 2

[0061] Example 2: 3000 tons / day advanced treatment industrial sewage purification recycling project.

[0062] The measured indicators of the sewage are shown in Table 4.

[0063] Table 4

[0064] serial number

[0065] 1

[0066] Step 1, electrolysis: start the water supply pump 12, and the sewage is 137m 3 The / h flow rate enters the electrolysis machine 13 through the stop valve 11 for electrolysis. The working voltage of electrolysis is 48V, the voltage between the two electrodes is 5.5-8.2V, and the current density is 190mA / cm 2 , Under the action of current, the nascent chlorine [Cl], hydroxyl [OH] and nascent oxygen [O] produced by electrolysis make the macromolecules in the sewage open or break the chain, improving the biodegradability of the sewage. At the same time, it oxidizes and decomposes organic matter, ammonia nitrogen, colored substances, etc. in wastewater, and makes suspended solids, colloids, and charged particles in wastewater form l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com